A Hybrid Excitation Switched Reluctance Motor with Modular Rotor

A technology of switched reluctance motor and mixed excitation, which is applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc. It can solve the problems of limiting the output capacity of the motor, affecting the mechanical strength of the rotor, and reducing the reliability of the motor, so as to achieve high electromagnetic utilization. , reduce the equivalent air gap length, reduce the effect of iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

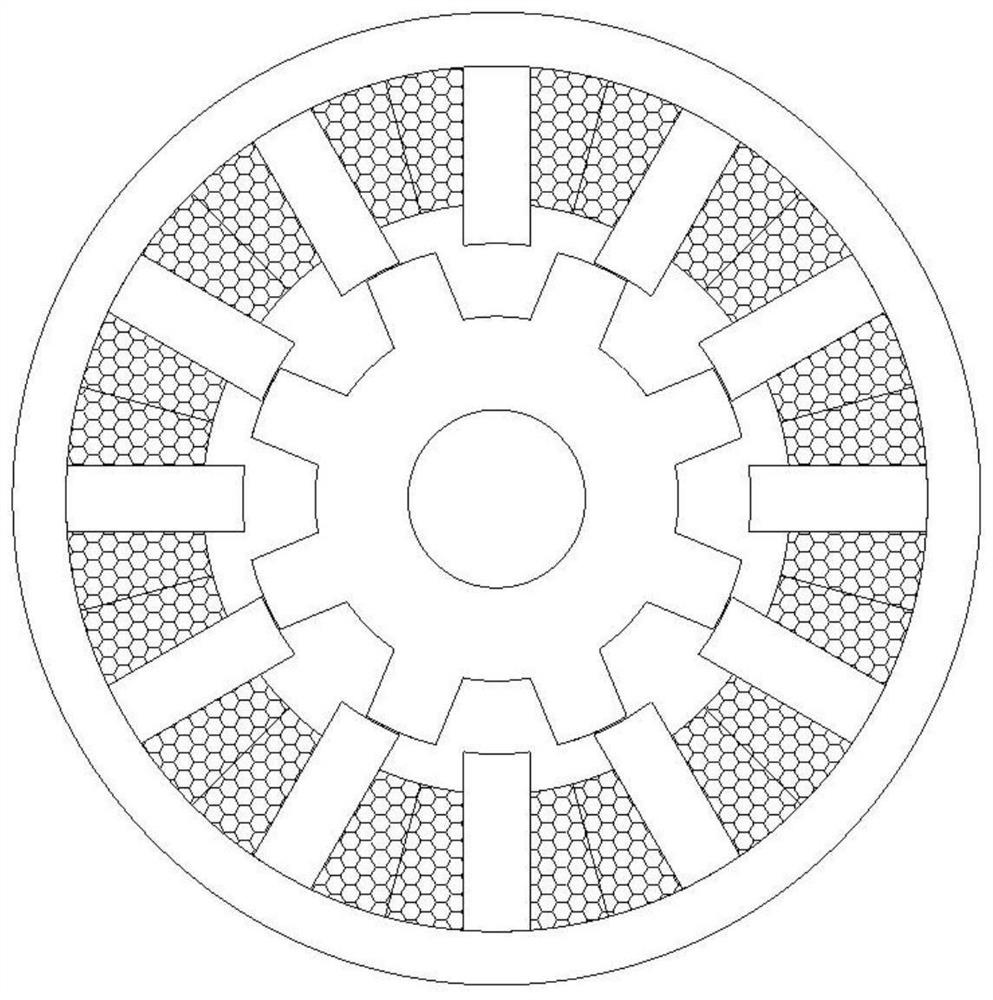

[0034] figure 1 It is a schematic diagram of a rotor modularized hybrid excitation switched reluctance motor of the present invention.

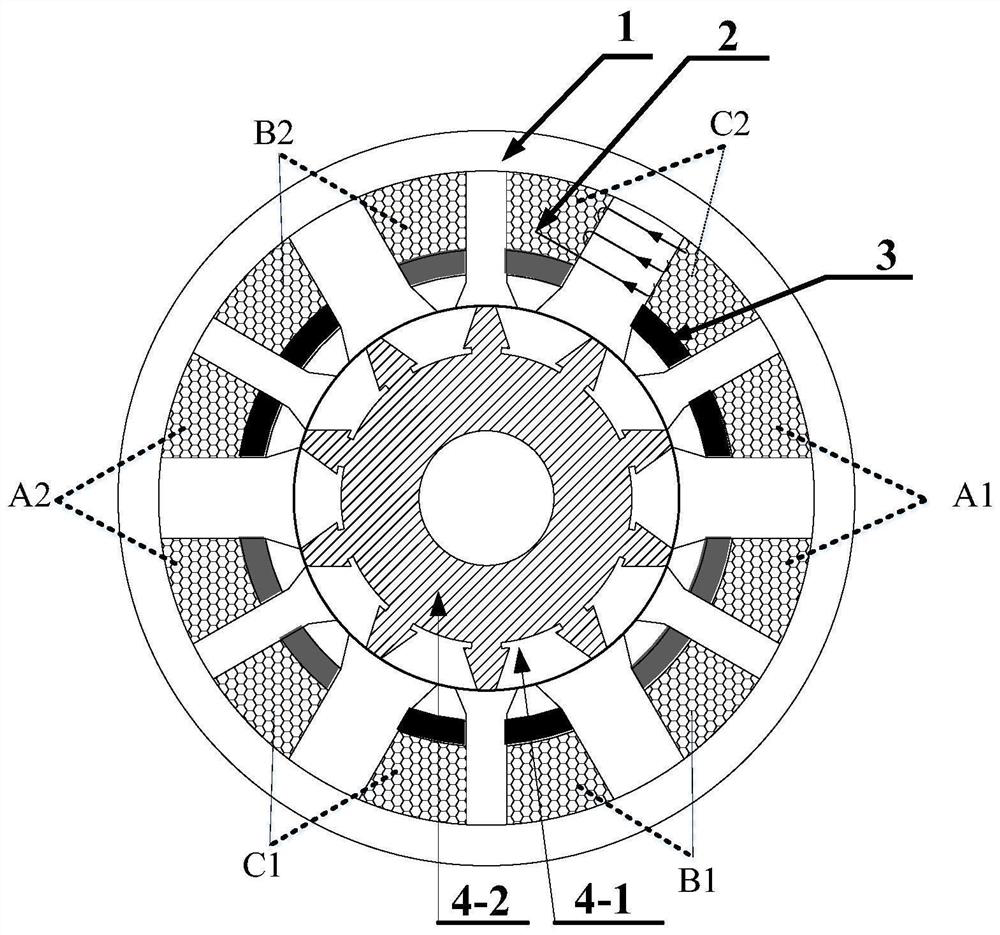

[0035] In this embodiment, as figure 2 As shown, the present invention is a rotor modular hybrid excitation switched reluctance motor, comprising: a stator core 1, an excitation winding coil 2, a permanent magnet 3, and a rotor 4;

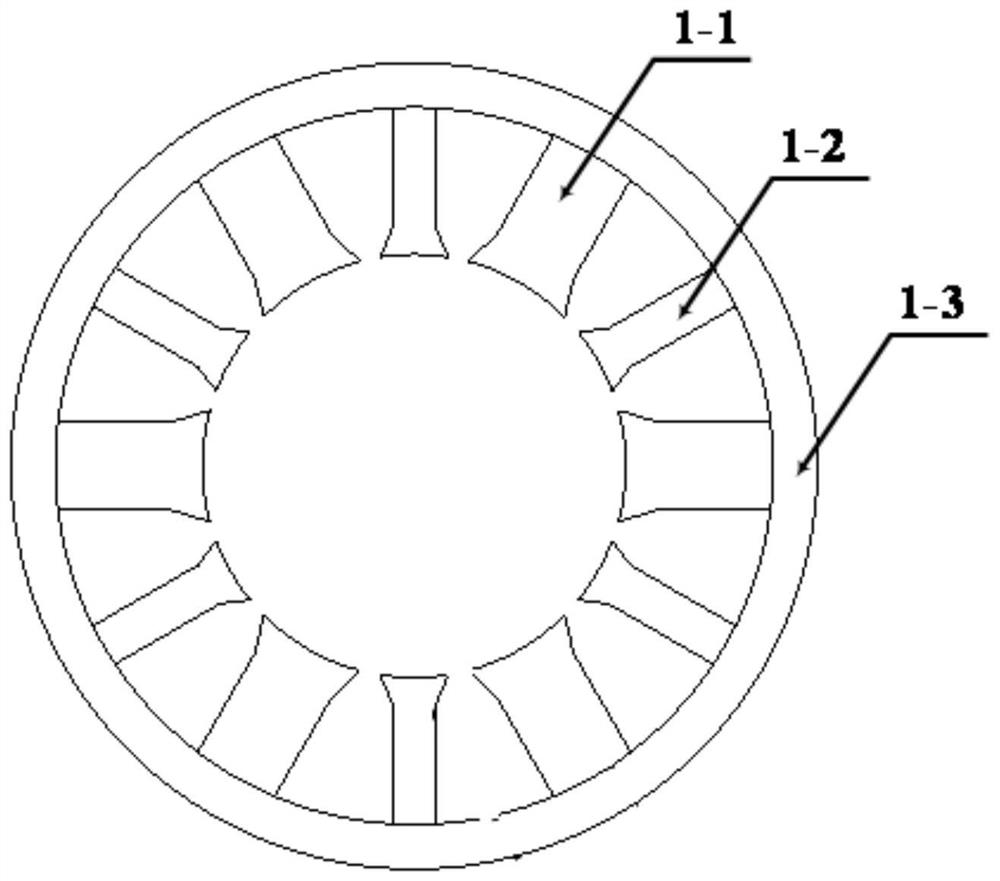

[0036] like image 3 As shown, the stator core 1 is a salient pole structure, including stator poles and stator yokes 1-3;

[0037] Among them, the stator yoke 1-3 is annular, and the stator poles are composed of six groups of excitation poles 1-1 and auxiliary poles 1-2 that are alternately and evenly distributed inside the stator yoke. The lower ends of the excitation poles and auxiliary poles are rectangular blocks, and the upper ends are It is an isosceles trapezoid block, but the upper bottom of the isosceles trapezoid block is an arc with the axis of the motor as the center of the circle; Figure 4 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com