Solid electrolyte based on iron pillared clay and ionic liquid and preparation method thereof

A solid electrolyte, ionic liquid technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems such as large influence, large interface resistance, and harsh preparation requirements, and achieve improved interface stability, high temperature stability, and interface. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of iron-pillared clay:

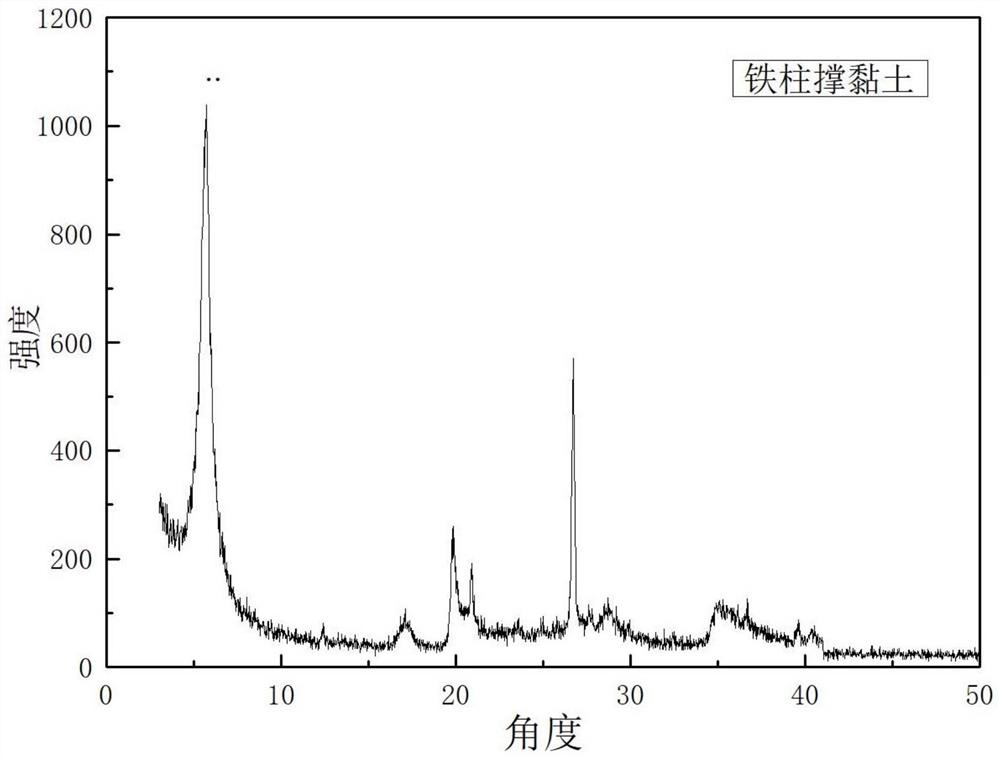

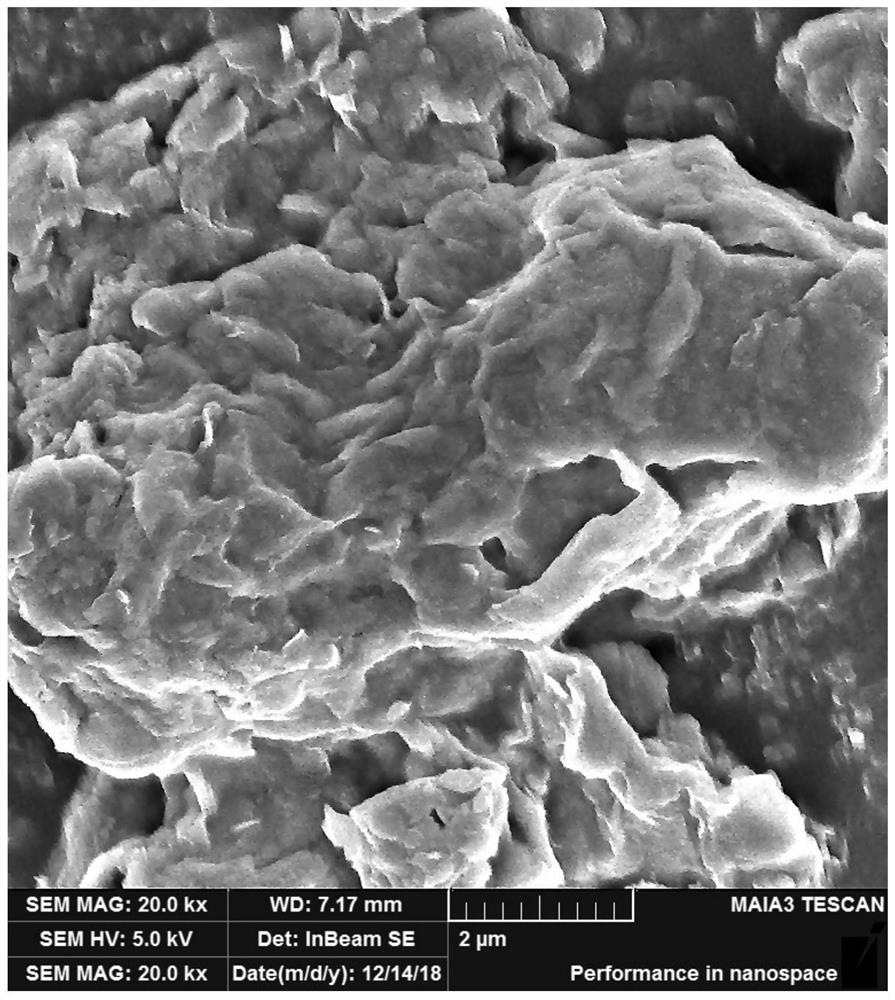

[0033] Add 250 mL of sodium carbonate solution with a concentration of 0.4 mol / L to 125 mL of ferric nitrate solution with a concentration of 0.4 mol / L dropwise under stirring, stir for 3 hours after the dropwise addition, then add 4 g of sodium-based montmorillonite, and ultrasonically treat it. 20min, stand for another 12h, centrifuge, add 500mL of deionized precipitate to centrifuge again (repeated 3 times), suction filtration, wash the solid obtained by suction filtration 5 times, and then place it in a drying box to dry at 80°C 8h, grinding to obtain iron-pillared clay (XRD pattern such as figure 1 As shown, the SEM image is as figure 2 shown).

[0034] Depend on figure 1 It can be seen that the pillar support of the iron pillar-supported clay is successful and has the expected structure.

[0035] Performance test of iron-pillared clay:

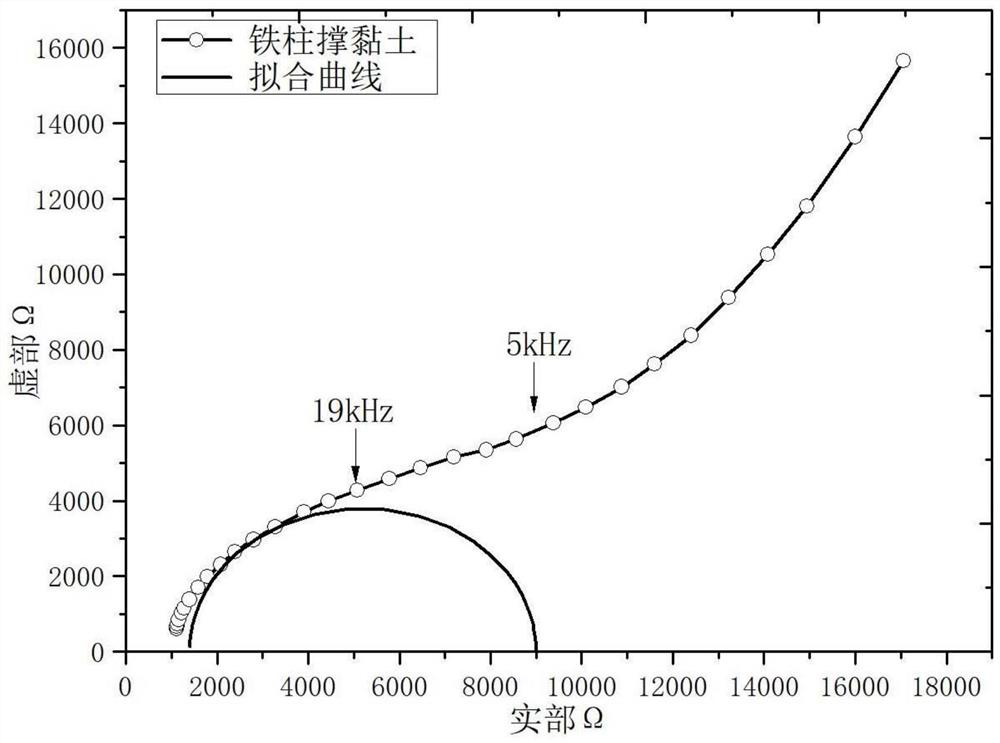

[0036] The iron-pillared clay was dried in a vacuum drying oven at 80 °C for 24 h, gr...

Embodiment 1

[0039] A solid electrolyte based on iron-pillared clay and ionic liquid, the preparation method comprising the following steps:

[0040] 1) Put lithium bistrifluoromethanesulfonimide, 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and iron-pillared clay in a vacuum drying oven, and dry at 80°C for 24h ;

[0041] 2) Under an argon atmosphere, bistrifluoromethanesulfonimide lithium and 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt are mixed uniformly to obtain a lithium salt-ionic liquid mixture (bis The mass ratio of lithium trifluoromethanesulfonimide to 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt is 1:19);

[0042] 3) In an argon atmosphere, mix the iron-pillared clay and the lithium salt-ionic liquid mixture evenly (the mass ratio of the iron-pillared clay and the lithium salt-ionic liquid mixture is 1:1.21), and then at a temperature of 1 °C / min. The rate of heating was increased to 150 °C, followed by calcination for 10 h...

Embodiment 2

[0045] A solid electrolyte based on iron-pillared clay and ionic liquid, the preparation method comprising the following steps:

[0046] 1) Put lithium bistrifluoromethanesulfonimide, 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt and iron-pillared clay in a vacuum drying oven, and dry at 80°C for 24h ;

[0047] 2) Under an argon atmosphere, bistrifluoromethanesulfonimide lithium and 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt are mixed uniformly to obtain a lithium salt-ionic liquid mixture (bis The mass ratio of lithium trifluoromethanesulfonimide and 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt is 1:3);

[0048] 3) In an argon atmosphere, mix the iron-pillared clay and the lithium salt-ionic liquid mixture evenly (the mass ratio of the iron-pillared clay and the lithium salt-ionic liquid mixture is 1:1.21), and then at a temperature of 1 °C / min. The rate was heated to 150 °C and calcined for 10 h to obtain a solid electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com