An optical correction method for reflective deimage rotation components of aerospace optical remote sensing instruments

A technology of optical remote sensing and optical correction, which is applied in optical components, instruments, optics, etc., can solve the problems of public reports on the optical correction of reflective anti-image rotation components of aerospace optical remote sensing instruments, etc., achieve fast and accurate correction, improve The effect of correcting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The optical correction of the reflective anti-image rotation component of the DQ-1 satellite wide imaging spectrometer has been successfully completed by using the above method.

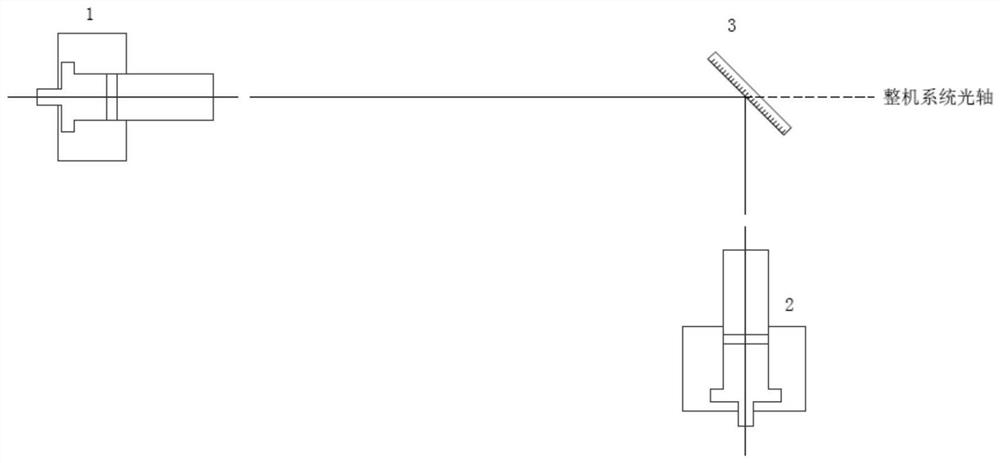

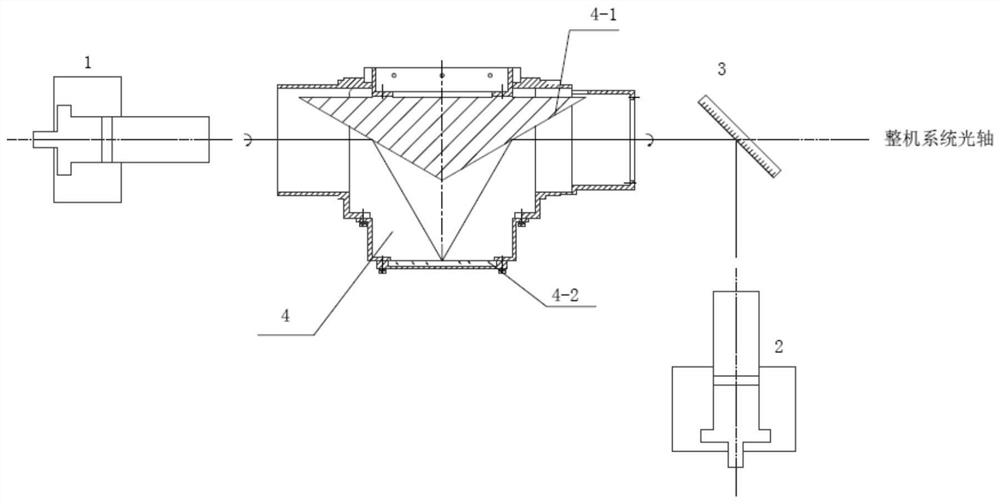

[0028] Such as figure 2 , adjust the central optical axis of the No. 1 internal focusing telescope 1 to coincide with the optical axis of the whole system, and pass the optical axis of the No. 2 internal focusing telescope 2 through the 45-degree turning plane mirror 3 and the No. 1 internal focusing telescope 1 The central optical axes of the telescopes coincide, that is, the central optical axes of the two inner focusing telescopes coincide and coincide with the optical axis of the whole machine system.

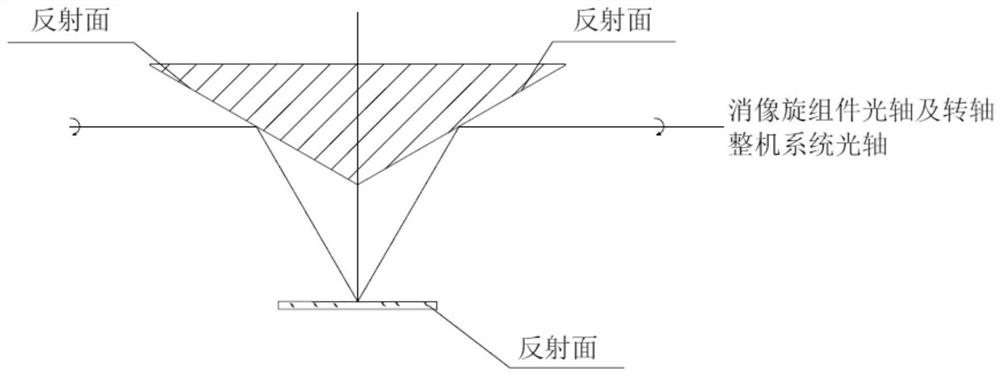

[0029] Paste the cross target paper on both ends of the hollow motor of the image elimination rotation assembly 4, so that the cross point on the target paper is the rotation center of the image elimination rotation assembly 4. Put the image elimination rotation assembly 4 into the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com