Deep foundation pit underground structure anti-floating system and construction process

It is a technology for underground structures and deep foundation pits, which is applied in the direction of foundation structure engineering, buildings, sheet pile walls, etc., and can solve problems such as difficulty in formwork support and waterproof construction, influence of structure anti-floating stability, and fatigue damage of bottom plate drawing, etc. To achieve the effect of ensuring the risk of uneven settlement of gaps, avoiding narrow backfill construction and formwork construction, and enhancing the anti-floating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

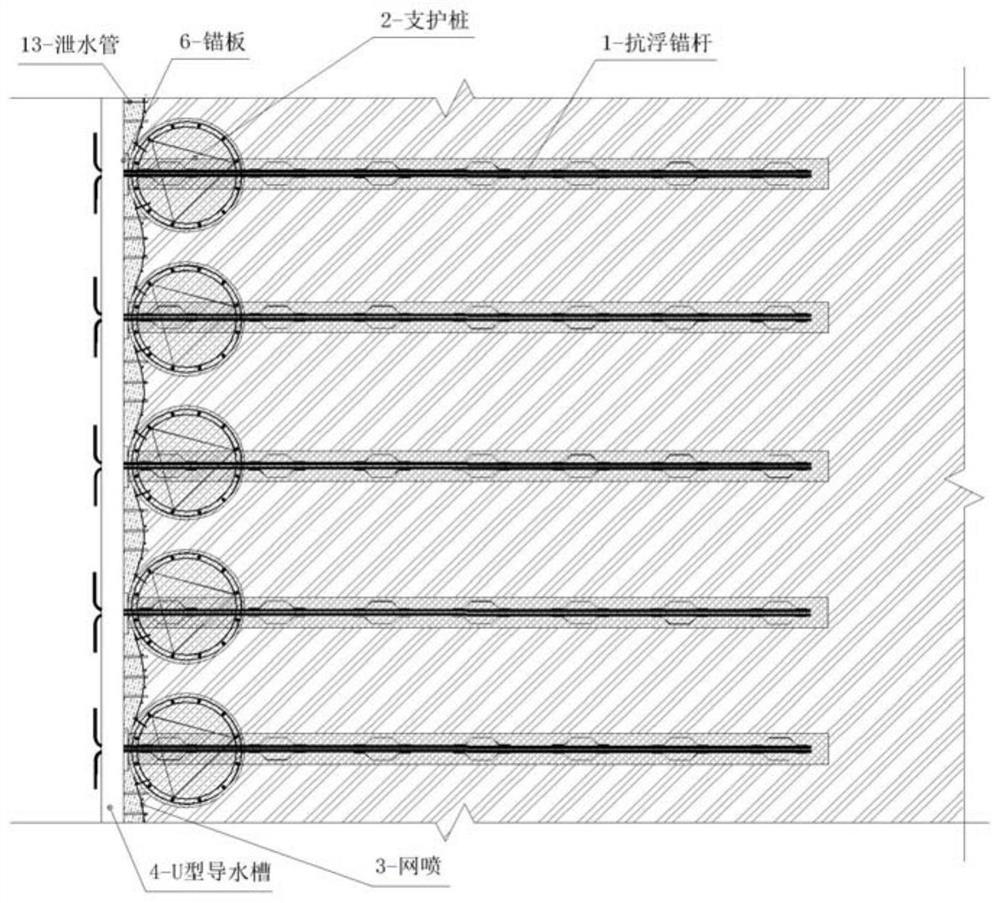

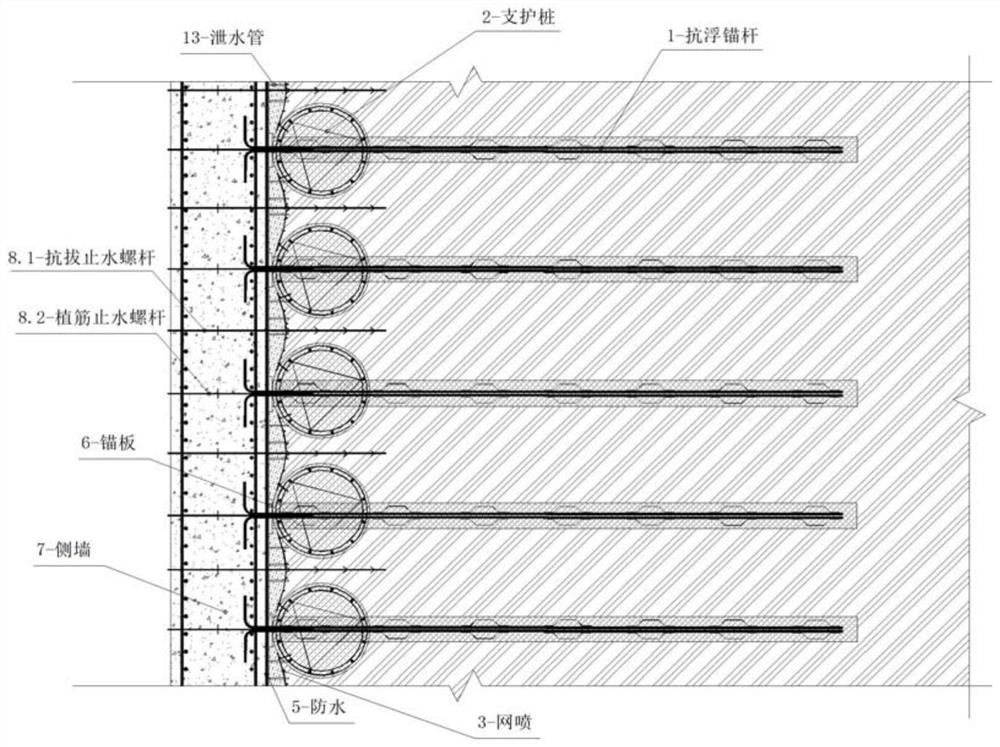

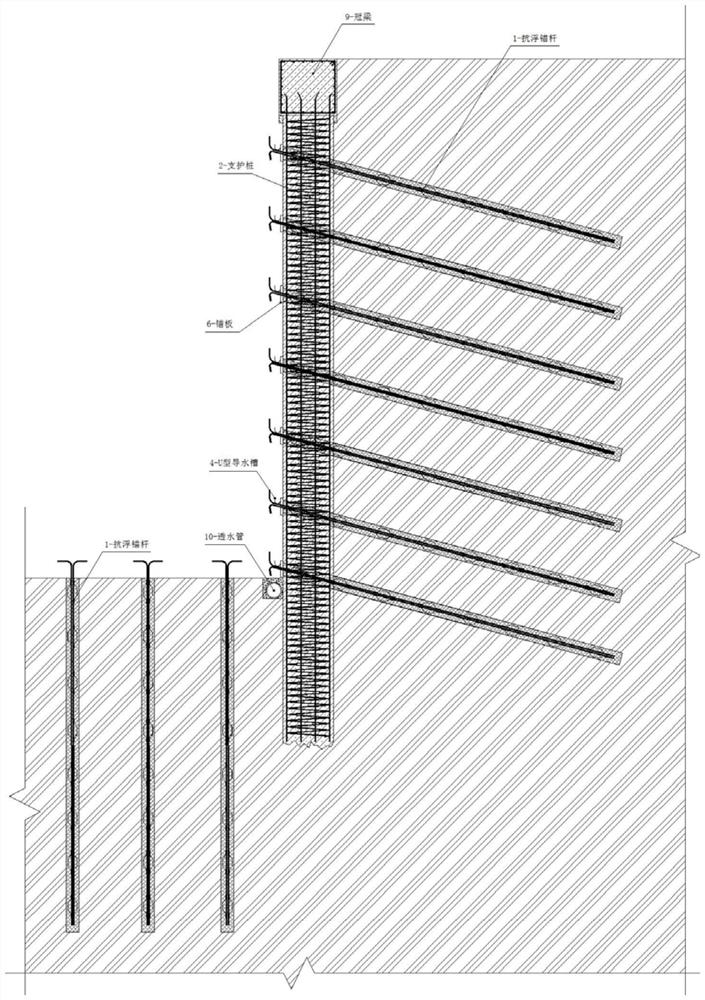

[0037]The invention discloses an anti-floating system for underground structures in deep foundation pits, which includes anti-floating anchor rods, anchor plates, support piles, crown beams, net spraying, drain pipes, U-shaped water guide channels, waterproofing, water sealing and leveling layers, water permeable Pipe, water stop screw, bottom plate, side wall plate and so on. Its structure adopts the anti-floating anchor rod as the anchor structure of the anchor pile, and the anchor plate is used to anchor the anti-floating anchor rod on the support pile. The beam is set on the top of the support piles to connect the support piles; the net sprayed structure is set between the support piles, and the net sprayed structure and the support piles are anchored by planting bars, and the net spray needs to be thickened to make the measured surface and The pile body is level and leveled manually; the U-shaped water guide groove is placed on the end of the anti-floating anchor rod and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com