Eco-friendly antibacterial laundry detergent

A kind of laundry detergent, environmental protection technology, applied in the field of laundry detergent, can solve the problems such as the weak decontamination effect of laundry detergent, and achieve the effect of improving washing-related performance, strong decontamination ability, and good antibacterial and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

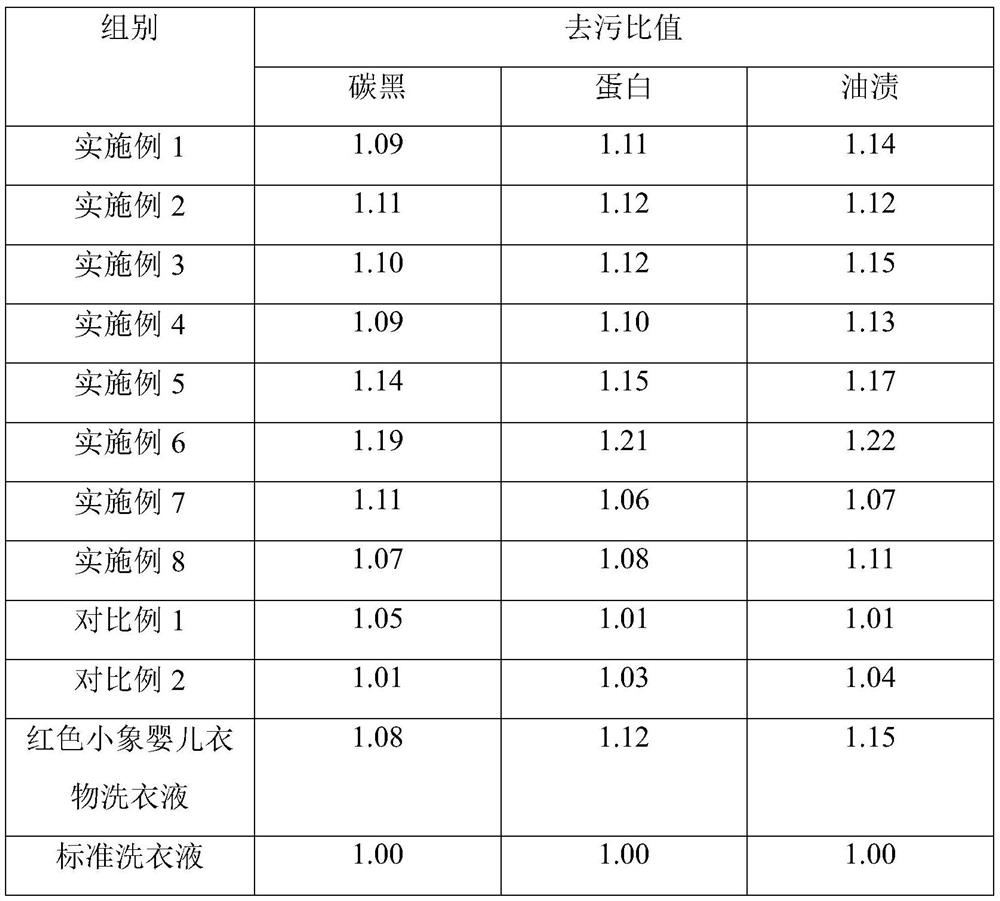

Embodiment 1

[0031] Embodiment 1 environmental protection antibacterial laundry detergent

[0032] Prepared from the following raw materials by weight percentage: saponin 0.5wt%, cactus total saponins 0.5wt%, cocamidopropylamine oxide 2wt%, lysozyme 0.1wt%, eucalyptus essential oil 0.1wt%, sorbitan Monooleate Polyoxyethylene Ether 3wt%, Xanthan Gum 0.5wt%, Disodium EDTA 0.01wt%, Cocamidopropyl Betaine 2.5wt%, Chitin 0.01wt%, Liquidambar Leaf Extract 0.1wt% and water balance.

[0033] The preparation method of cactus total saponins is as follows:

[0034] S1. Rinse the cactus, crush it to below 100 mesh, and dry it at 50°C for 1 hour to obtain a powder with a water content of 1 wt%;

[0035] S2. Add 0.5L of the powder obtained in step S1 into a WZJ-6BI vibrating ultrafine pulverizer, add 70 media, and perform ultrafine pulverization for 15 minutes to obtain an ultrafine powder with a particle size below 300 mesh;

[0036] S3. Add the superfine powder obtained in step S2 into glycerol, th...

Embodiment 2

[0044] Embodiment 2 environmental protection antibacterial laundry detergent

[0045] Prepared from the following raw materials by weight percentage: Quillaja saponins 2wt%, cactus total saponins 3wt%, cocamidopropylamine oxide 5wt%, lysozyme 0.5wt%, peppermint essential oil 0.3wt%, sorbitan mono-oil Ester polyoxyethylene ether 6wt%, xanthan gum 1.5wt%, EDTA disodium 0.2wt%, cocamidopropyl betaine 4wt%, chitin 0.1wt%, sweetgum leaf extract 0.3wt% and water quantity.

[0046] The preparation method of cactus total saponins is as follows:

[0047] S1. Rinse the cactus, crush it to below 100 mesh, and dry it at 70°C for 3 hours to obtain a powder with a water content of 5wt%;

[0048] S2. Add 0.7L of the powder obtained in step S1 into a WZJ-6BI vibrating ultrafine pulverizer, add 80 media, and perform ultrafine pulverization for 30 minutes to obtain an ultrafine powder with a particle size below 300 mesh;

[0049] S3. Add the superfine powder obtained in step S2 into glycerol...

Embodiment 3

[0057] Embodiment 3 environmental protection antibacterial laundry detergent

[0058] Prepared from the following raw materials by weight percentage: Quillaja saponins 0.7wt%, cactus total saponins 0.9wt%, cocamidopropylamine oxide 3wt%, lysozyme 0.2wt%, rose essential oil 0.15wt%, sorbitan Monooleate Polyoxyethylene Ether 4wt%, Xanthan Gum 0.7wt%, EDTA Disodium 0.05wt%, Cocamidopropyl Betaine 3wt%, Chitin 0.05wt%, Liquidambar Leaf Extract 0.15wt% and water balance.

[0059] The preparation method of cactus total saponins is as follows:

[0060] S1. Rinse the cactus, crush it to below 100 mesh, and dry it at 55°C for 2 hours to obtain a powder with a water content of 2wt%;

[0061] S2. Add 0.55L of the powder obtained in step S1 into a WZJ-6BI type vibrating ultrafine pulverizer, add 72 media, and perform ultrafine pulverization for 17 minutes to obtain an ultrafine powder with a particle size below 300 mesh;

[0062] S3. Add the superfine powder obtained in step S2 into gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com