Dicing device for seafood processing

A seafood and dicing technology, which is applied in metal processing, cutting fish into components, etc., can solve the problems of dicing size difference, low dicing efficiency, affecting the consistent packaging process of dicing, etc. The effect of improving work efficiency and improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

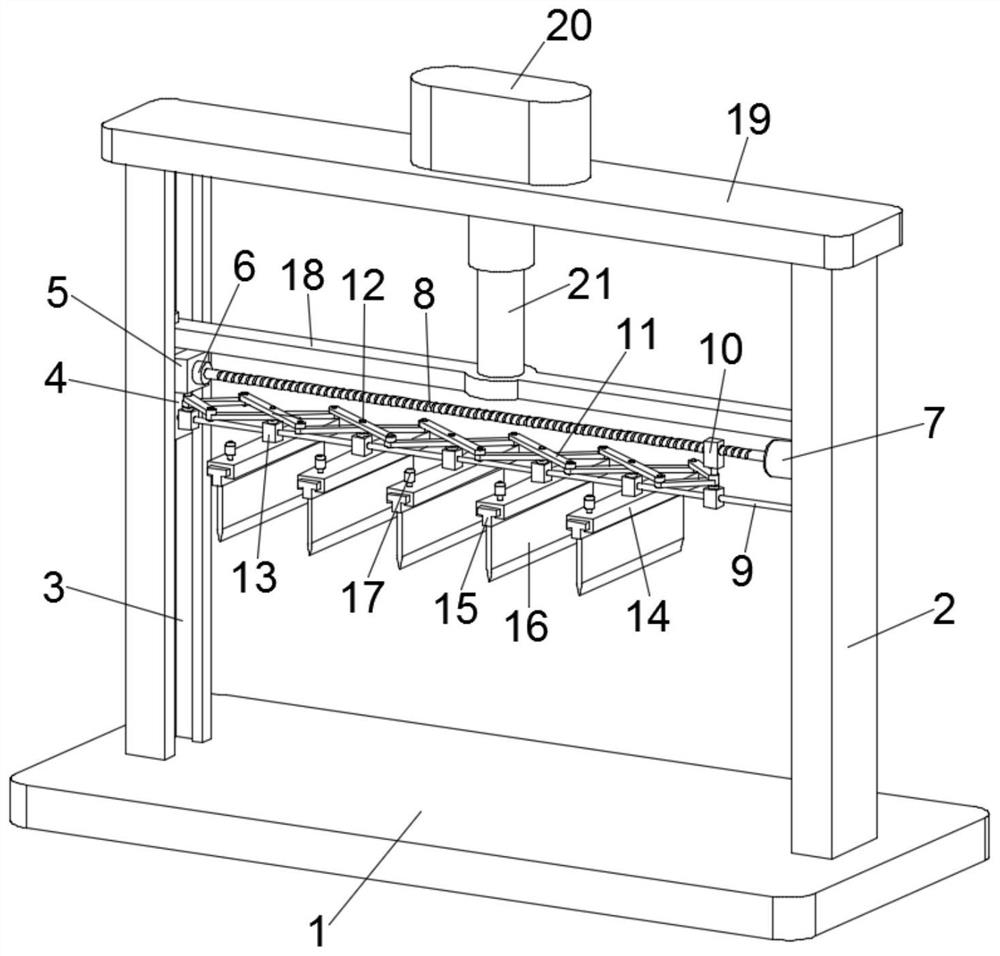

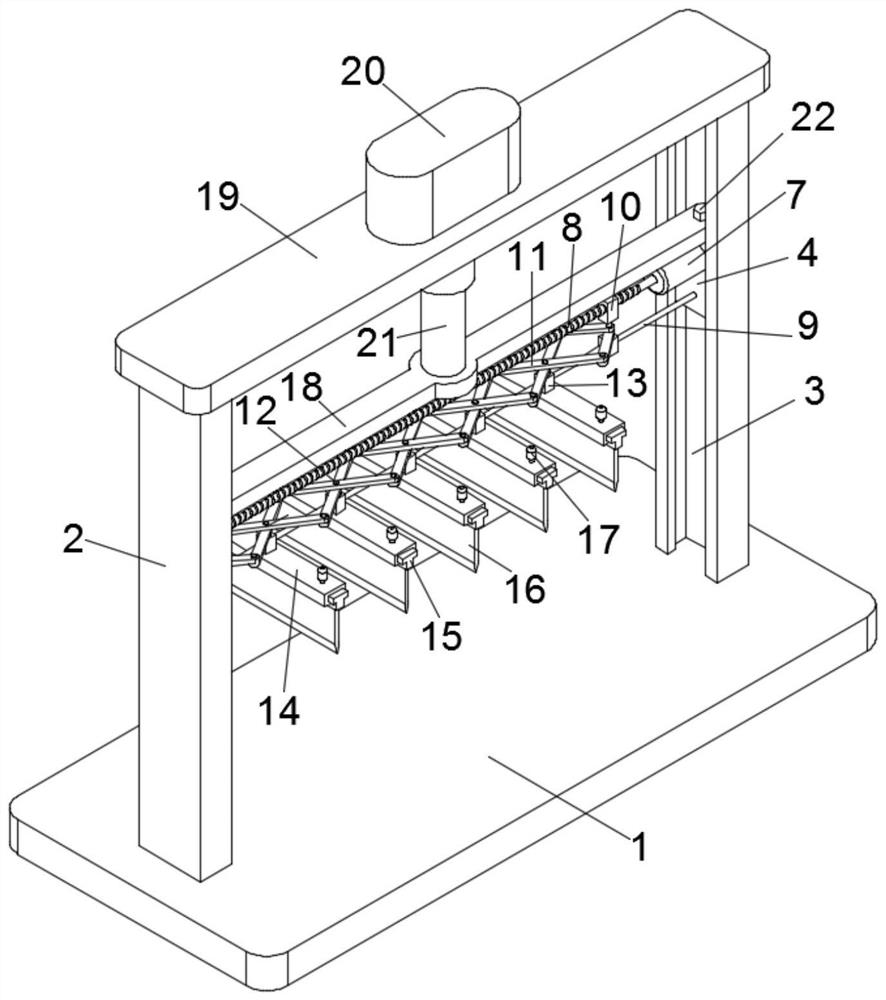

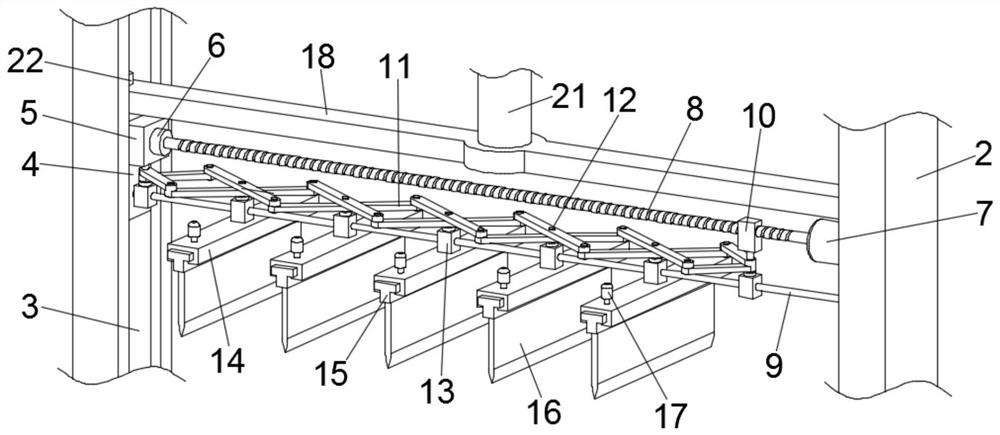

[0027] see Figure 1-2 , a kind of cutting device for seafood processing, comprising a workbench 1, a support plate 2 is installed vertically symmetrically on both sides of the workbench 1, a chute 3 is provided in the support plate 2, and a chute 3 is provided in the chute 3 Slide block 4 is embedded in vertical sliding, and fixed block 5 is installed on one side slide block 4, and bearing housing 6 is arranged on described fixed block 5, and adjustment motor 7 is installed on the other side slide block 4, and described adjustment A screw 8 is installed horizontally between the motor 7 and the bearing seat 6, and the screw sleeve 10 is provided on the screw sleeve on the screw rod 8;

[0028] see image 3 , a scissors mechanism is connected between the spiral sleeve 10 and the fixed block 5, the scissors mechanism is hinged by several connecting rods 11, the middle parts of each connecting rod are connected by a central hinge shaft 12, the two of the scissors mechanism The ...

Embodiment 2

[0039]A dicing device for seafood processing, comprising a workbench 1, a support plate 2 is symmetrically and vertically installed on both sides of the workbench 1, a chute 3 is opened in the support plate 2, and a vertical chute 3 is provided inside the chute 3 The straight slide is embedded with a slider 4, a fixed block 5 is installed on the slider 4 on one side, a bearing seat 6 is arranged on the fixed block 5, and an adjusting motor 7 is installed on the slider 4 on the other side, and the adjusting motor A screw rod 8 is horizontally installed between the 7 and the bearing seat 6, the screw sleeve on the screw rod 8 is provided with a helical sleeve 10, and a scissor mechanism is connected between the helical sleeve 10 and the fixed block 5, and the scissor mechanism consists of several The connecting rods 11 are hinged, and the middle parts of each connecting rod are connected by the central hinge shaft 12. The two ends of the scissor mechanism are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com