Cutting structure for cutting slab rubber into rubber strips

A technology of plastic sheeting and forming glue, applied in metal processing and other directions, can solve the problems of low production efficiency of manual cutting, expensive equipment, complicated cutting equipment, etc., and achieve the effects of simple structure, convenient operation and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

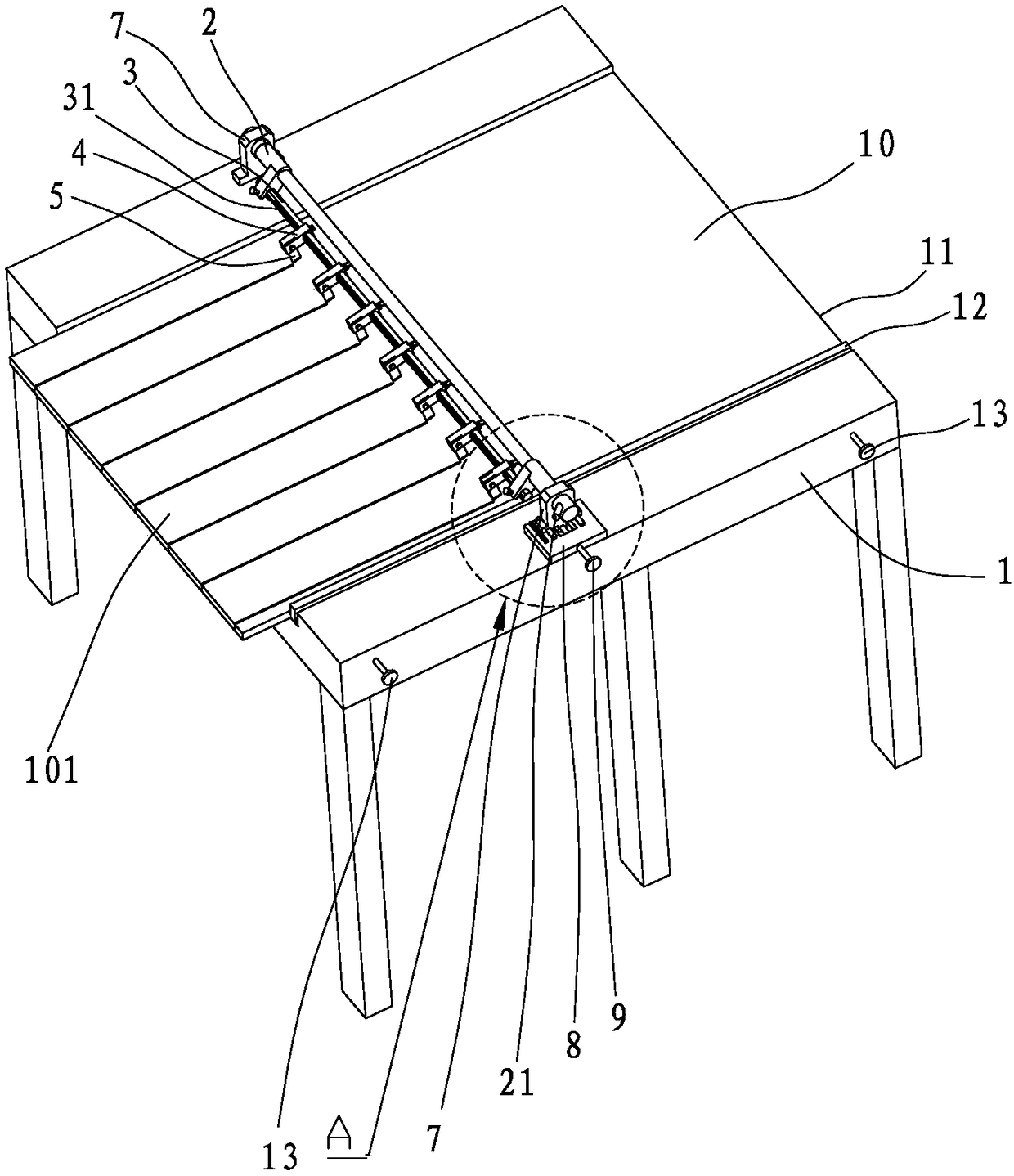

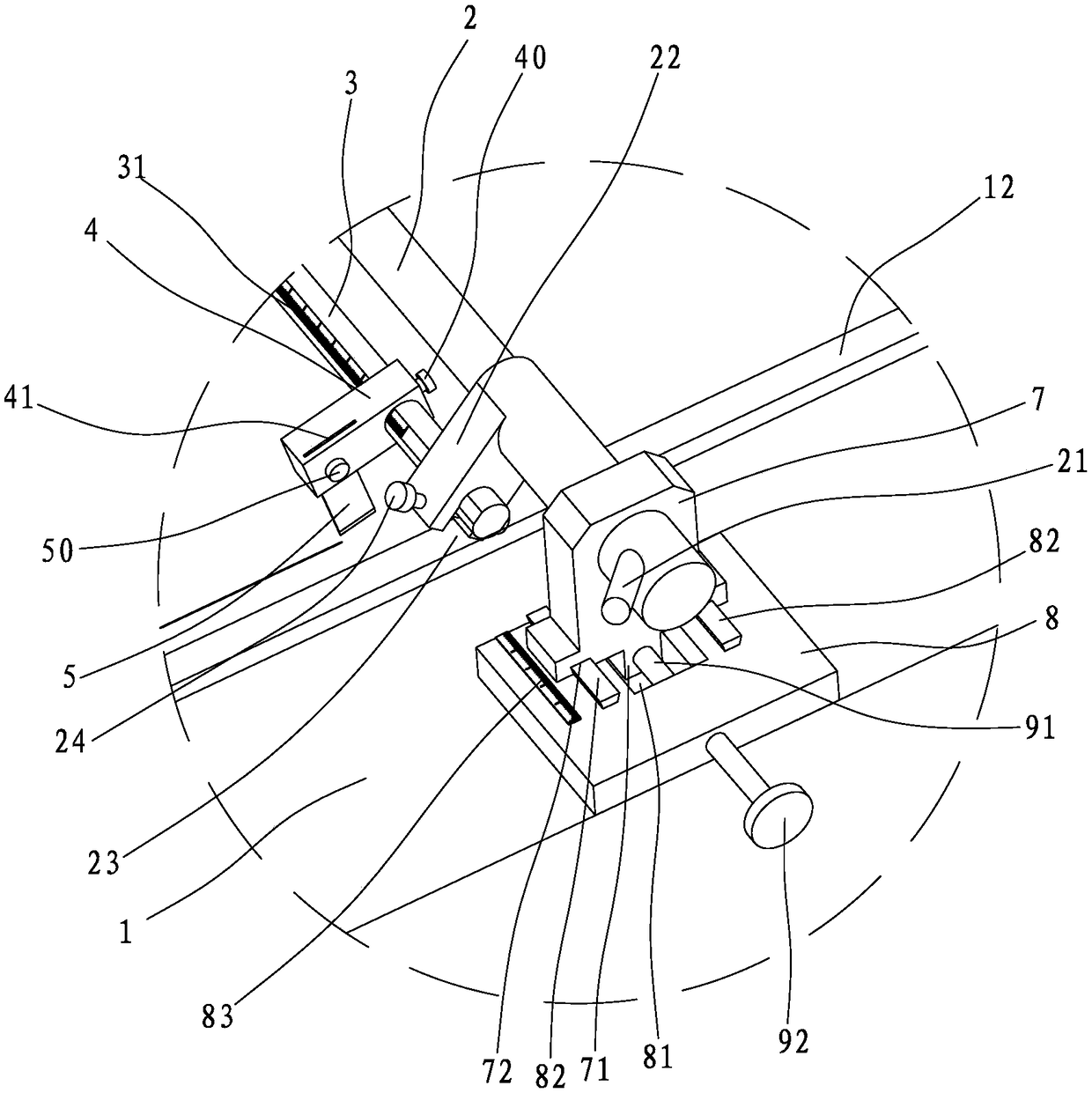

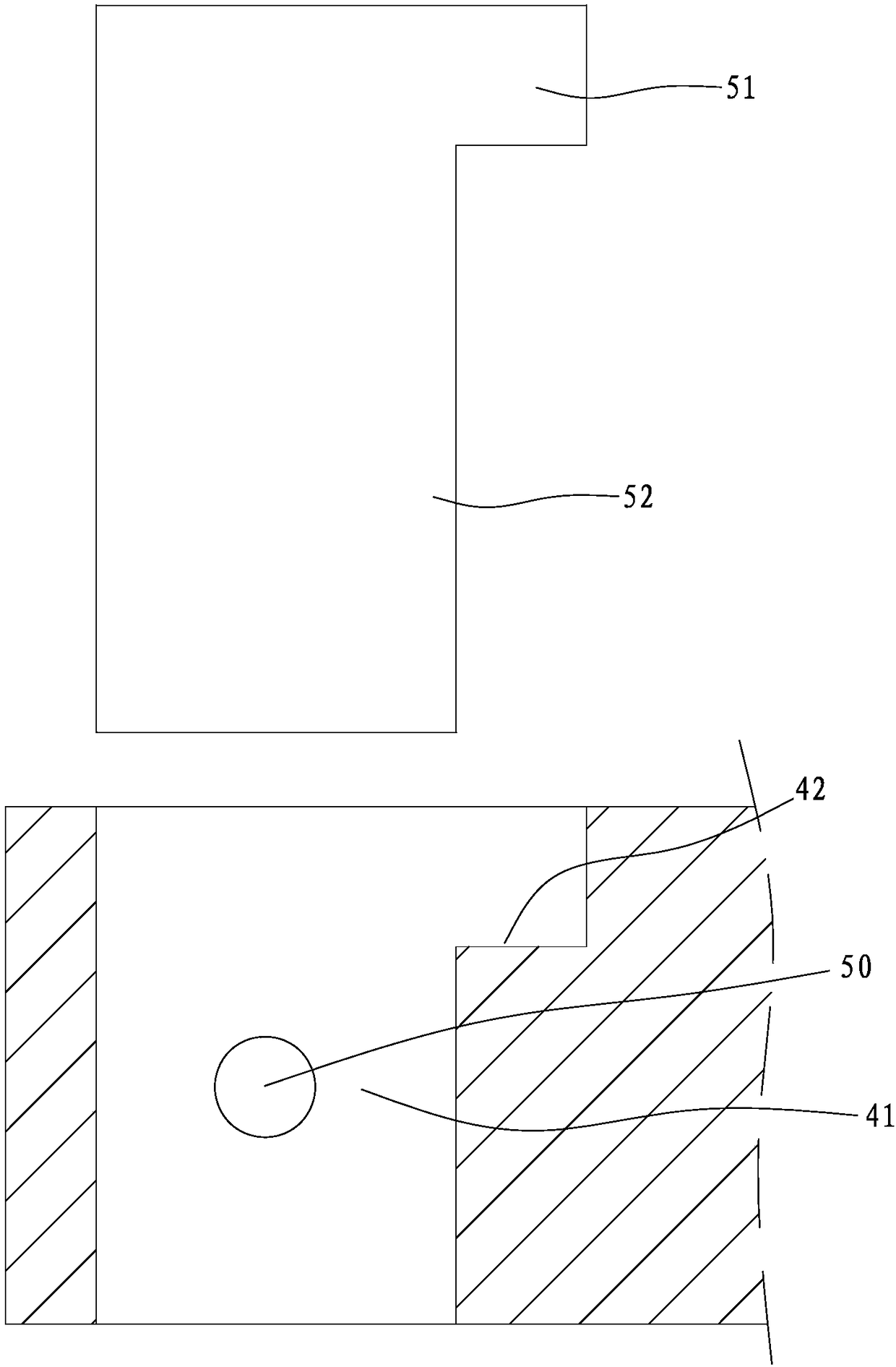

[0025] Such as Figure 1 to Figure 3 A split structure for dividing rubber sheets into rubber strips is shown, including a workbench 1, which is provided with a concave flow channel 11 for the rubber sheet 10 to move longitudinally inside. The workbench 1 is provided with an adjustment plate 12 that can adjust the working width of the flow channel 11, and an adjustment screw 13 that can adjust the left and right positions of the adjustment plate 12 in the flow channel 11. By rotating the adjustment screw 13, the adjustment plate 12 is driven in the flow channel. 11 to move left and right to adjust the left and right positions of the adjustment plate 12 on the flow channel, so that the working width of the flow channel 11 can be adjusted according to the rubber sheets 10 of different width specifications, and one machine with multiple functions can be realized.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com