Preparation method and application of modified locust tree leaf charcoal

A technology of biochar and pagoda tree leaves, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of high cost, secondary pollution of the environment, and high requirements for production equipment, and achieve low cost, avoid pollution, The effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

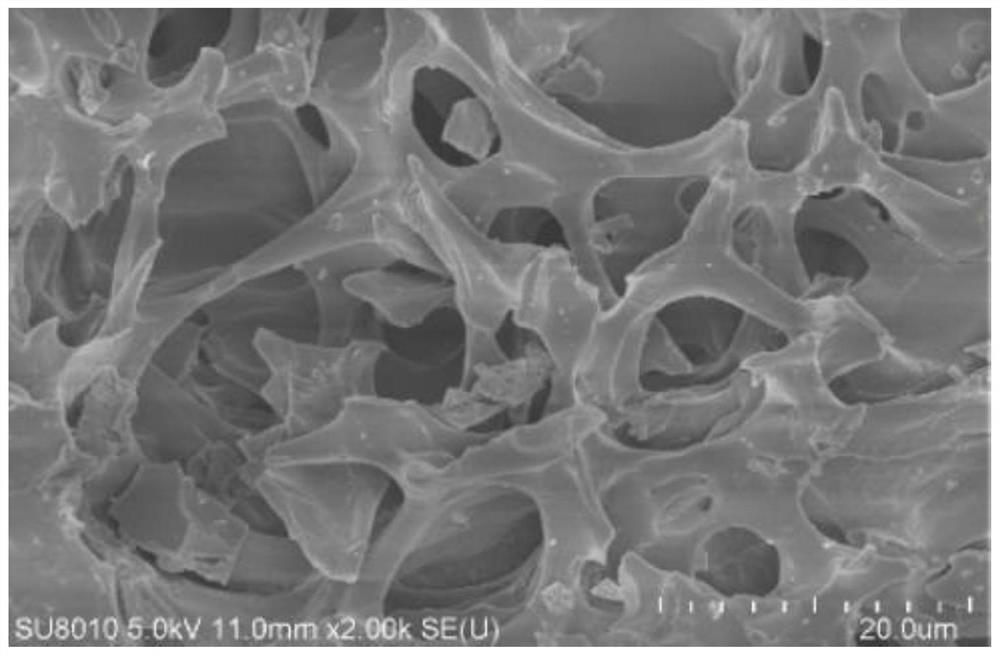

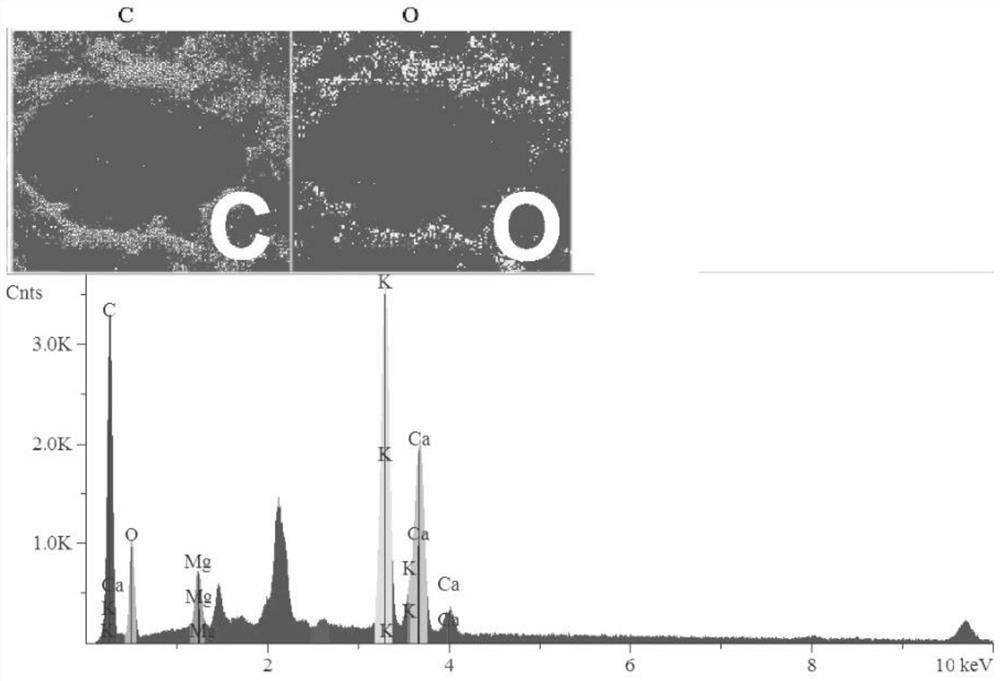

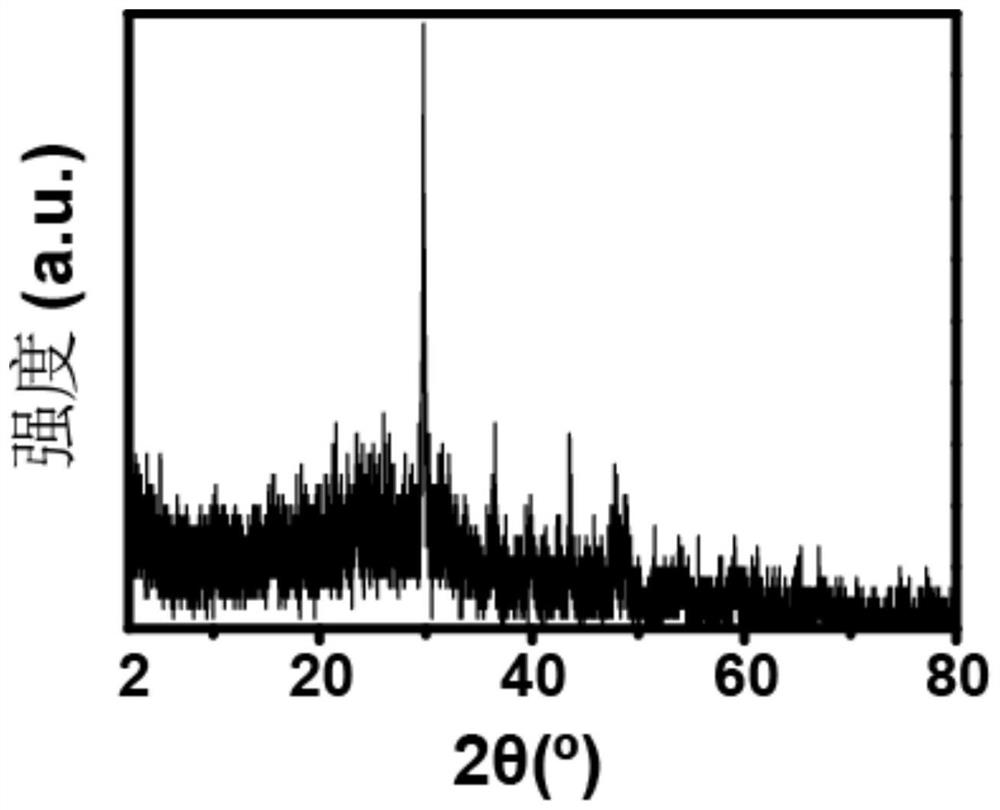

[0030] A preparation method of modified locust tree leaf biochar, comprising the following steps:

[0031] (1) Take locust tree leaves as raw material, wash them with tap water and dry them, place the dried locust tree leaves in a pulverizer to fully crush them, pass the crushed materials through a 50-mesh sieve, put the sieved locust tree leaves in chlorine Immerse in zinc chloride solution for 24 hours, filter and dry, then transfer the dried pagoda tree leaves to a vacuum furnace, raise the temperature to 450°C at 10°C / min under an inert atmosphere, and keep at 450°C for 3h to carbonize the material. After carbonization, cool down to room temperature naturally, then pass through NaOH solution and reversely spray the material in the vacuum furnace, let it stand for 0.5h, filter, and dry to obtain the initial activated biochar;

[0032] (2) Place the initially activated biochar in a vacuum furnace and reactivate it under an inert atmosphere at 500°C for 1 hour, cool to room t...

Embodiment 2

[0036] The modified locust tree leaf biochar was prepared according to the preparation method of Example 1 and used to adsorb bisphenol A, an organic pollutant in polluted water sources, except that the carbonization temperature in step (1) was 650°C.

Embodiment 3

[0038] The modified pagoda tree leaf biochar was prepared according to the preparation method of Example 1 and used to adsorb bisphenol A, an organic pollutant in polluted water sources, except that the carbonization temperature in step (1) was 850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com