Preparation method of composite fruit and vegetable powder

The technology of fruit and vegetable powder and mango freeze-dried powder is applied in the directions of preservation of fruits and vegetables, forming of food, function of food ingredients, etc. Good industrial prospects, convenient to eat, and the effect of prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

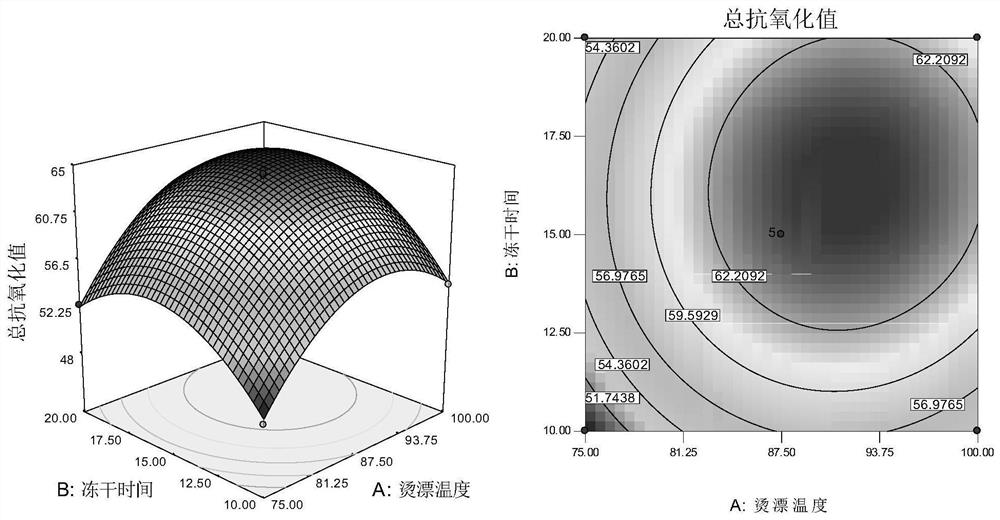

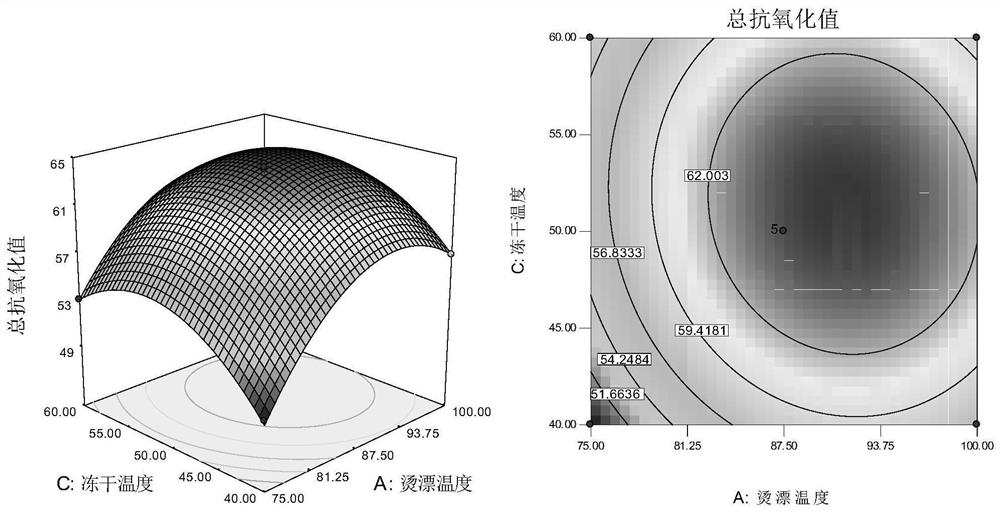

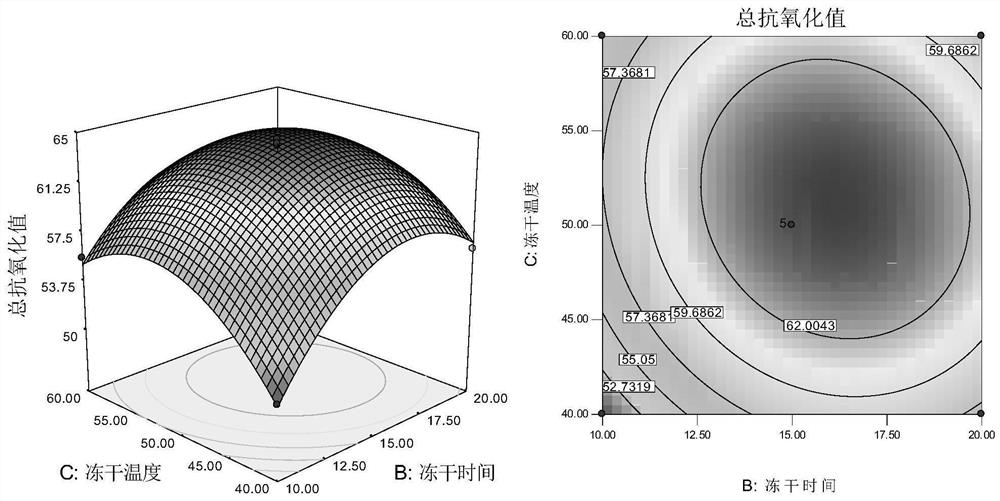

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of composite fruit and vegetable powder, comprising the following steps:

[0041] (1) Select fresh yams and bananas, wash and peel them, cut yams and bananas into 6mm thick slices respectively, and soak them for 20 minutes with 0.05% citric acid by mass fraction;

[0042] (2) Vacuum freeze-drying the soaked yam slices and banana slices at a cold trap temperature of -40°C, a vacuum degree of 100Pa, and a heating plate temperature of 60°C for 16 hours to obtain yam freeze-dried tablets and banana freeze-dried tablets;

[0043] (3) Select fresh jackfruit and mango, wash, peel and remove the core, cut the mango into thin slices with a thickness of 0.5cm, and blanch the sliced mango and jackfruit meat separately, and the blanching temperature of both is 70 ℃, blanching time is 15s;

[0044] (4) Freeze-dry the blanched mango slices and jackfruit meat respectively. The freeze-drying temperature of the mango slices is 30° C., and the freeze-drying time i...

Embodiment 2

[0048] A preparation method of composite fruit and vegetable powder, comprising the following steps:

[0049] (1) Select fresh yams and bananas, wash and peel them, cut yams and bananas into 6mm thick slices respectively, and soak them for 20 minutes with 0.05% citric acid by mass fraction;

[0050] (2) Vacuum freeze-drying the soaked yam slices and banana slices at a cold trap temperature of -40°C, a vacuum degree of 100Pa, and a heating plate temperature of 60°C for 16 hours to obtain yam freeze-dried tablets and banana freeze-dried tablets;

[0051] (3) Select fresh jackfruit and mango, wash, peel and remove the core, cut the mango into thin slices with a thickness of 0.5cm, and separately blanch the cut mango slices and jackfruit meat. The blanching temperature of the mango slices is 89°C , the blanching time is 45s, the blanching temperature of jackfruit meat is 84°C, and the blanching time is 45s;

[0052] (4) Freeze-dry the blanched mango slices and jackfruit meat resp...

Embodiment 3

[0056] A preparation method of composite fruit and vegetable powder, comprising the following steps:

[0057] (1) Select fresh yams and bananas, wash and peel them, cut yams and bananas into 6mm thick slices respectively, and soak them for 20 minutes with 0.05% citric acid by mass fraction;

[0058] (2) Vacuum freeze-drying the soaked yam slices and banana slices at a cold trap temperature of -40°C, a vacuum degree of 100Pa, and a heating plate temperature of 60°C for 16 hours to obtain yam freeze-dried tablets and banana freeze-dried tablets;

[0059] (3) Select fresh jackfruit and mango, wash, peel and remove the core, cut the mango into thin slices with a thickness of 0.5cm, and separately blanch the cut mango slices and jackfruit meat. The blanching temperature of both is 100 ℃, blanching time is 45s;

[0060] (4) Freeze-dry the blanched mango slices and jackfruit meat respectively. The freeze-drying temperature of the mango slices is 60° C., and the freeze-drying time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com