Enhanced quadrupole high-speed synchronous motor rotor damping structure

A high-speed synchronous motor rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of poor starting performance, high installation cost, and large contact resistance of four-pole high-speed synchronous motors, and achieve The effect of improving material utilization, reducing the amount of copper and iron, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

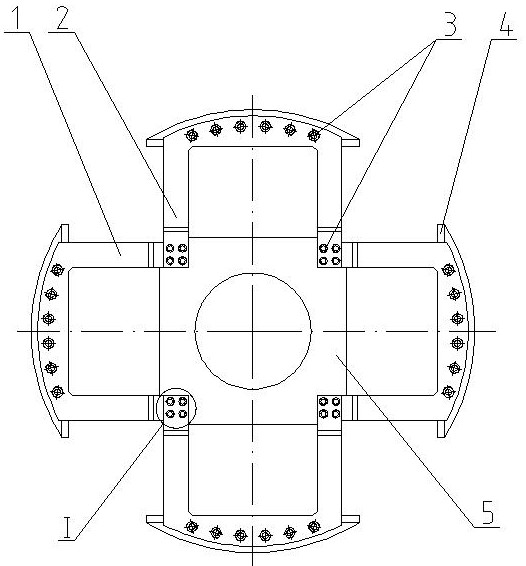

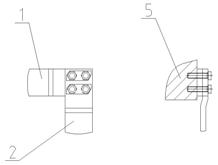

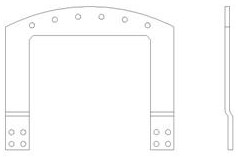

[0010] The present invention will be further described below in conjunction with accompanying drawings and examples. Such as figure 1 As shown, it includes (1) damping ring, (2) damping ring, (3) high strength bolt, (4) pole piece, (5) yoke, (6) silver spacer.

[0011] The damping ring is designed to be 冂 type, (1) damping ring and (2) damping ring are 2 pieces at each end, a total of 4 pieces at each end, when installing, first use (1) damping ring and (2) damping ring alternately ( 3) High-strength bolts are installed on the end face of (4) pole shoe, and the connecting parts of two adjacent damping rings are designed as a high-low lap joint structure, misaligned at right angles to each other, and fixed together on (5) yoke with (3) high-strength bolts On the end face, a tight fit. In order to solve the problem of excessive contact resistance between (4) pole piece end face and (1) damping ring, a layer of (6) silver gasket is placed between the two, and at the same time b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com