Vehicle-mounted fuel cell system and fuel cell vehicle

A fuel cell system and fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of stack failure, complicated circuit design, unusable fuel cell systems, etc., and achieve good insulation. performance, improved security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

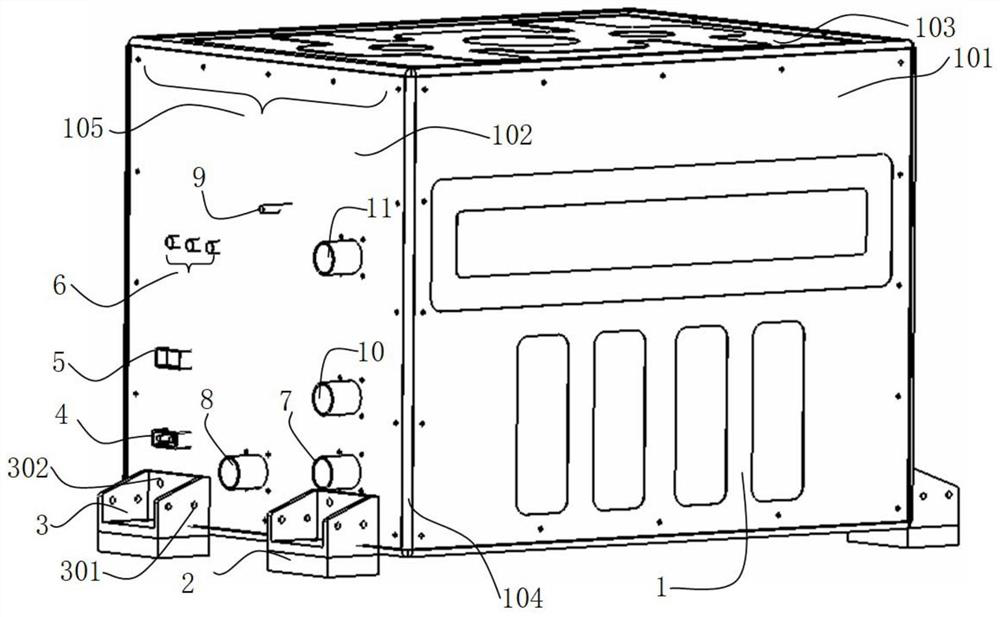

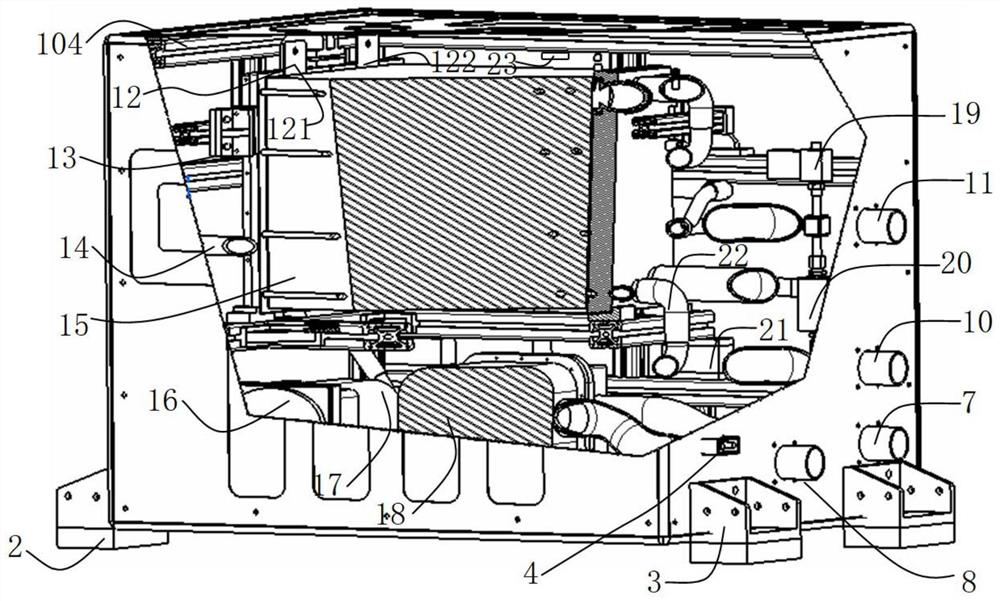

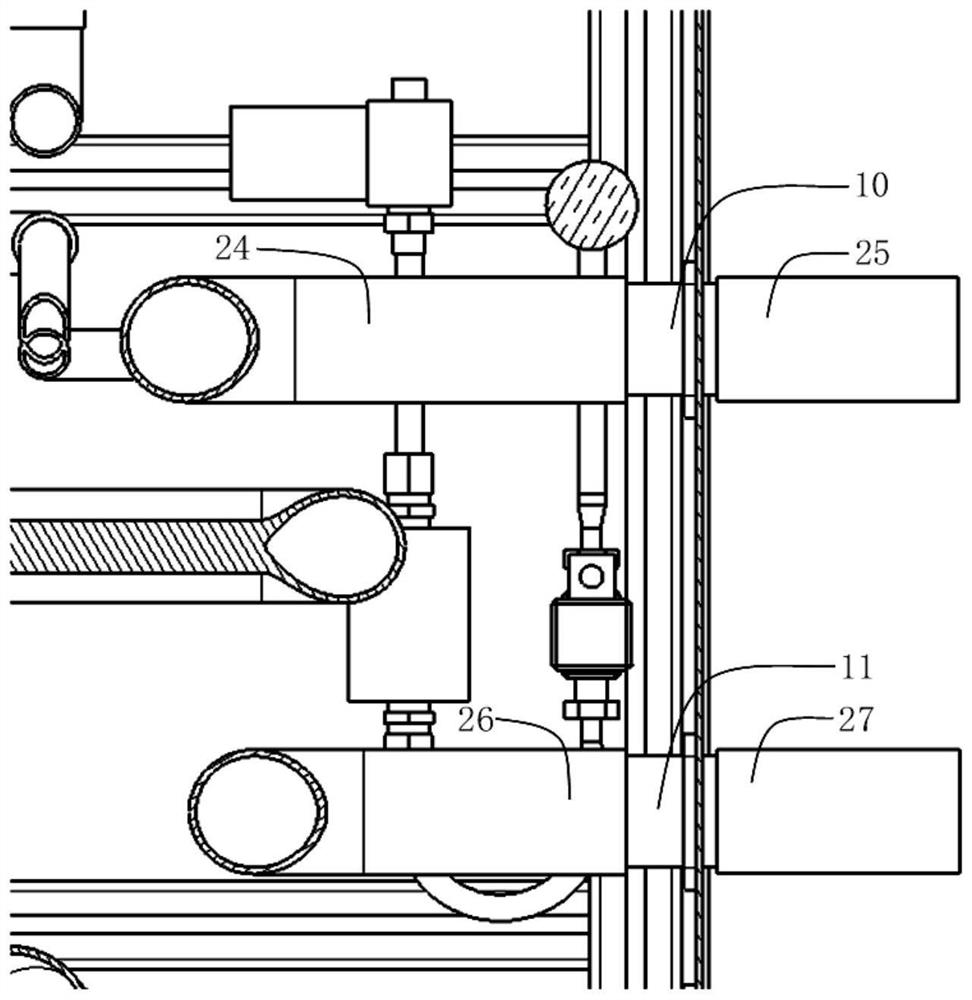

Embodiment 1

[0062] In the vehicle-mounted fuel cell system of this embodiment, the first panel 101, the second panel 102 and the third panel 103 are made of aluminum alloy material, the main frame is made of CFRP material, and the mounting bracket 3 is made of aluminum alloy material. The thickness of the installation pad 2 is 60mm, the thickness of the buffer block 21 is 40mm, the main controller connection terminal 5, the power output terminal 4, the low-voltage drive power supply and the control signal connection terminal 6 are all IP67 protection grades, the air intake pipe 7 and the air The gas outlet pipe 8 is made of HDPE material, the hydrogen inlet pipe 9 is made of stainless steel, the first liquid passing pipe 11 and the second liquid passing pipe 10 are made of HDPE material, and the hydrogen return pipeline 14 and the hydrogen exhaust pipeline 22 are made of Made of stainless steel, the electric stack 15 has a power of 90kW, the gas-water separator 16 is a cyclone-type gas-wat...

Embodiment 2

[0066] In the vehicle-mounted fuel cell system of this embodiment, the first panel 101, the second panel 102 and the third panel 103 are made of CFRP material, the main frame is made of CFRP material, and the mounting bracket 3 is made of aluminum alloy material. The thickness of the block 2 is 20mm, the thickness of the buffer block 21 is 20mm, the main controller connection terminal 5, the power output terminal 4, the low-voltage drive power supply and the control signal connection terminal 6 are all IP67 protection grades, the air inlet pipe 7 and the air outlet The air pipe 8 is made of PA6 material, the hydrogen inlet pipe 9 is made of stainless steel, the first liquid passing pipe 11 and the second liquid passing pipe 10 are made of PTFE material, the hydrogen return pipeline 14 and the hydrogen exhaust pipeline 22 are made of stainless steel The electric stack 15 has a power of 72kW, the gas-water separator 16 is a cyclone-type gas-water separator, and the humidifier 18 ...

Embodiment 3

[0070] In the vehicle-mounted fuel cell system of this embodiment, the first panel 101, the second panel 102 and the third panel 103 are made of aluminum alloy material, the main frame is made of aluminum alloy material, and the mounting bracket 3 is made of aluminum alloy material , the thickness of the mounting block 2 is 40mm, the thickness of the buffer block 21 is 30mm, the main controller connection terminal 5, the power output terminal 4, the low-voltage drive power supply and the control signal connection terminal 6 are all IP67 protection grades, the air intake pipe 7 and The air outlet pipe 8 is made of PVC material, the hydrogen inlet pipe 9 is made of stainless steel, the first liquid passing pipe 11 and the second liquid passing pipe 10 are made of POM material, the hydrogen return pipeline 14 and the hydrogen exhaust pipeline 22 Made of stainless steel, the electric stack 15 has a power of 56kW, the gas-water separation device 16 is a cyclone-type gas-water separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com