Jacking and descending platform for shield station passing, shield station passing system and construction method

A construction method and station passing technology, which is applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of high construction cost and long time consumption, and achieve the effect of reducing construction difficulty, simple structure, and complex station structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

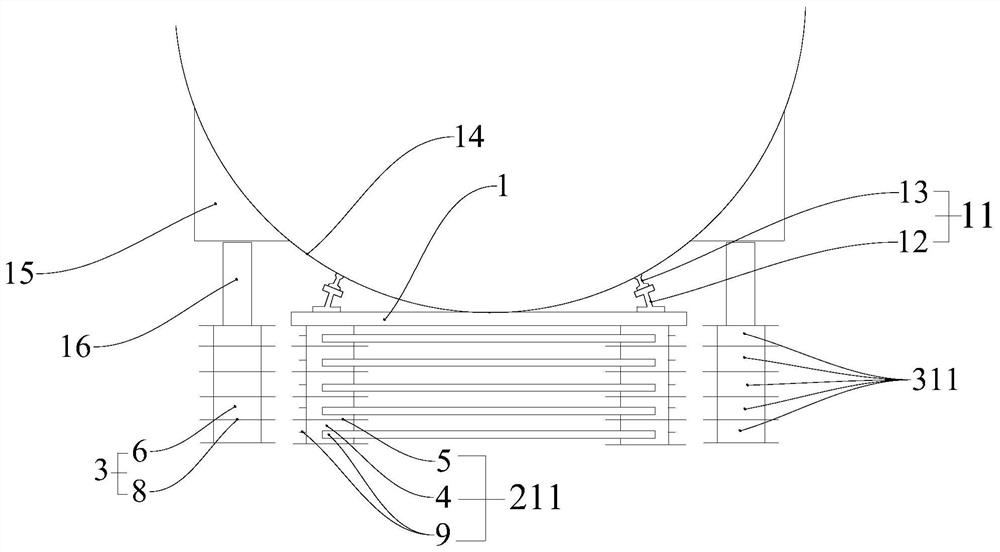

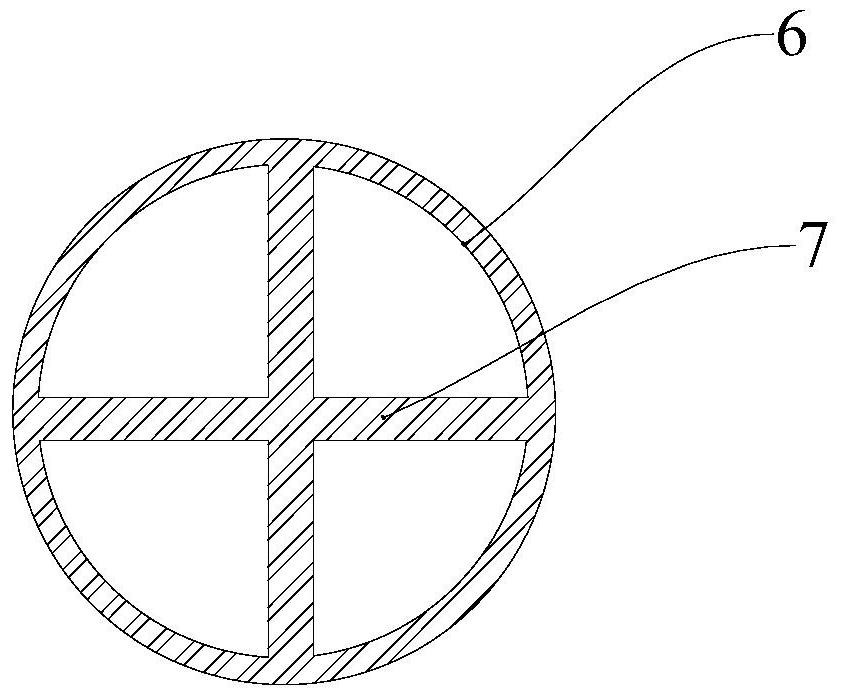

[0040] A shield passing station system, comprising a shield passing lifting and lowering platform and a shield moving device, the shield passing lifting and lowering platform includes a bracket 1, a bracket base 2 and a jacking base Seat 3; the bracket 1 is rectangular, the bracket 1 is arranged above the bracket base 2, the bracket base 2 includes a multi-layer first cushion layer 211, and each layer of the first cushion layer 211 It includes a plurality of first steel cylinders 4, and the plurality of first steel cylinders 4 are rectangularly distributed, including two rows. In this embodiment, each row of bracket bases 2 is provided with six first steel cylinders 4 with a spacing of 1600mm; Wherein, the diameter of the first steel cylinder 4 is 609mm. Specifically, first steel plates 5 are fully welded on the upper and lower surfaces of each first steel cylinder 4, and the specification of each first steel plate 5 is 70mm*70mm *10mm, the height of each layer of steel cylind...

Embodiment 2

[0047] A shield tunneling station construction method, using a shield tunneling station system of embodiment 1, specifically includes the following steps:

[0048] S1: Preparations before construction: Verify the detailed height from the station floor to the bottom of the middle plate, and meet the station passing conditions when the clearance height is greater than the shield machine 14 height of 300mm or more;

[0049] S2: Installation of the shield passing system: install the platform for the shield machine 14 to descend in advance at the position of the lower step; then stake out and mark the position of the upper step;

[0050] Specifically, the installation process of the forward moving system of the shield machine is as follows: weld the second section steel 19 on the two sides of the front and rear ends of the shield machine 14 respectively, and install a pulley 23 on each second section steel 19; A lifting lug 22 and a reaction support 17 is installed on the first sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com