Intelligent well head safety control system with flow monitoring

A technology of safety control and flow monitoring, which is applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc. It can solve problems such as safety valve leakage valve opening degree, leakage measurement monitoring, safety accidents, etc. To achieve the effect of improving safety production operation, reducing loss of production stoppage, and satisfying intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

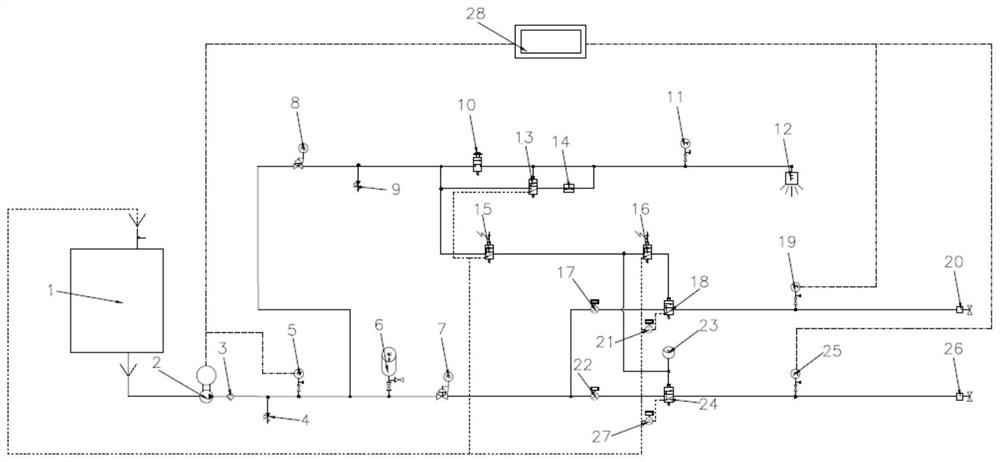

[0043] As attached figure 1 As shown, an intelligent wellhead safety control system with flow monitoring includes a high-pressure hydraulic system, a safety valve hydraulic control main road, a low-pressure control system, and a host computer control system 28.

[0044] The high-pressure hydraulic system includes: an oil tank 1, an electric hydraulic pump 2, a one-way valve 3, a first safety valve 4, a first pressure transmitter 5, an accumulator 6 and a first pressure regulating valve 7. The output end of the first pressure regulating valve 7 is respectively connected to the input end of the hydraulic control branch of the uphole safety valve and the hydraulic control branch of the downhole safety valve.

[0045] The safety valve hydraulic control main road includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com