Riverway anti-blocking type environment-friendly dredging vehicle and dredging method

A dredging truck and anti-clogging technology, which can be applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the clogging of dredging heads, the influence of dredging efficiency, and the adsorption of flaring parts. Small force and other problems to avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

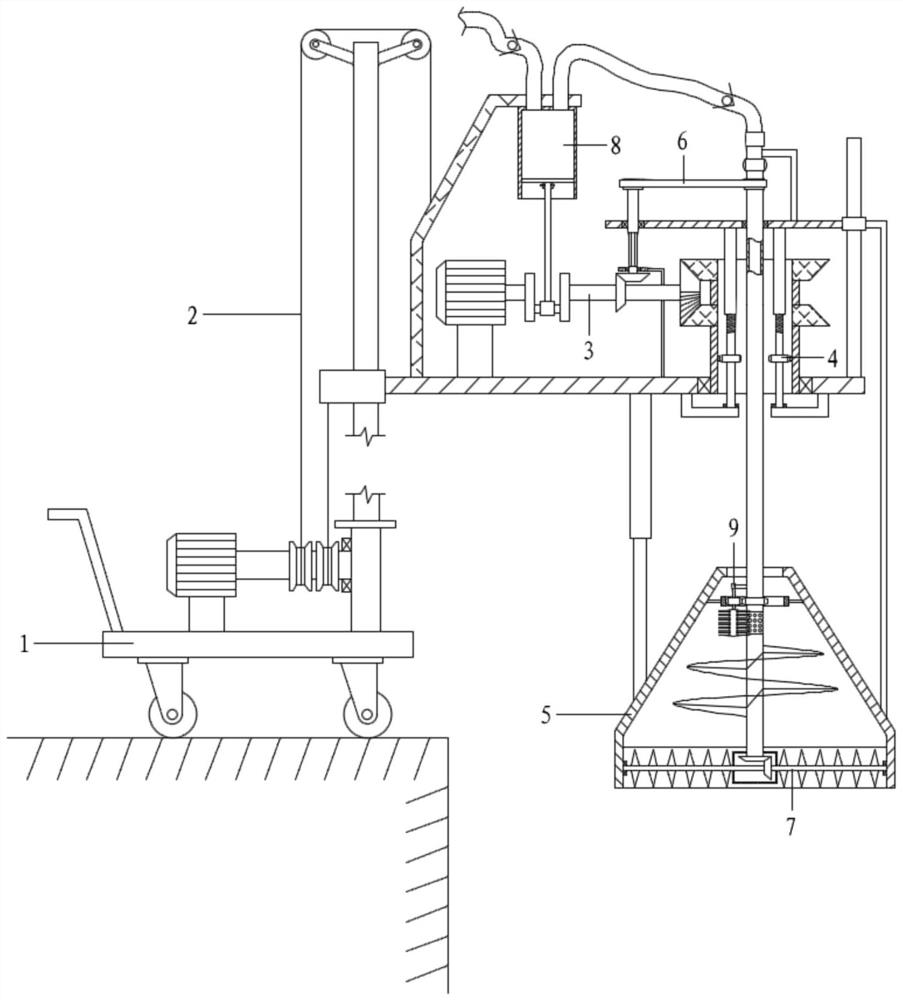

[0069] With reference to the accompanying drawings, an environmentally-friendly dredging vehicle with anti-clogging type for river channels includes a vehicle body assembly 1, a lifting assembly 2, a power assembly 3, a reciprocating assembly 4, a cover assembly 5, a negative pressure assembly 6 and a crushing assembly 7;

[0070] The car body assembly 1 includes a car plate 101, wheels 102, handlebars 103, a No. 1 support plate 104, a fixed plate 105, a No. 1 sliding rod 106, a No. 1 sliding sleeve 107 and a No. 2 support plate 108; the bottom of the car plate 101 is installed Wheel 102, a handlebar 103 is connected to the left side of the car plate 101; a support plate 104 is fixed to the car plate 101, a fixing plate 105 is fixed to the top of the first support plate 104, and a sliding rod 106 is fixed to the fixing plate 105 , The No. 1 sliding rod 106 is covered with a No. 1 sliding sleeve 107, and the right side of the No. 1 sliding sleeve 107 is connected with a No. 2 suppo...

Embodiment 2

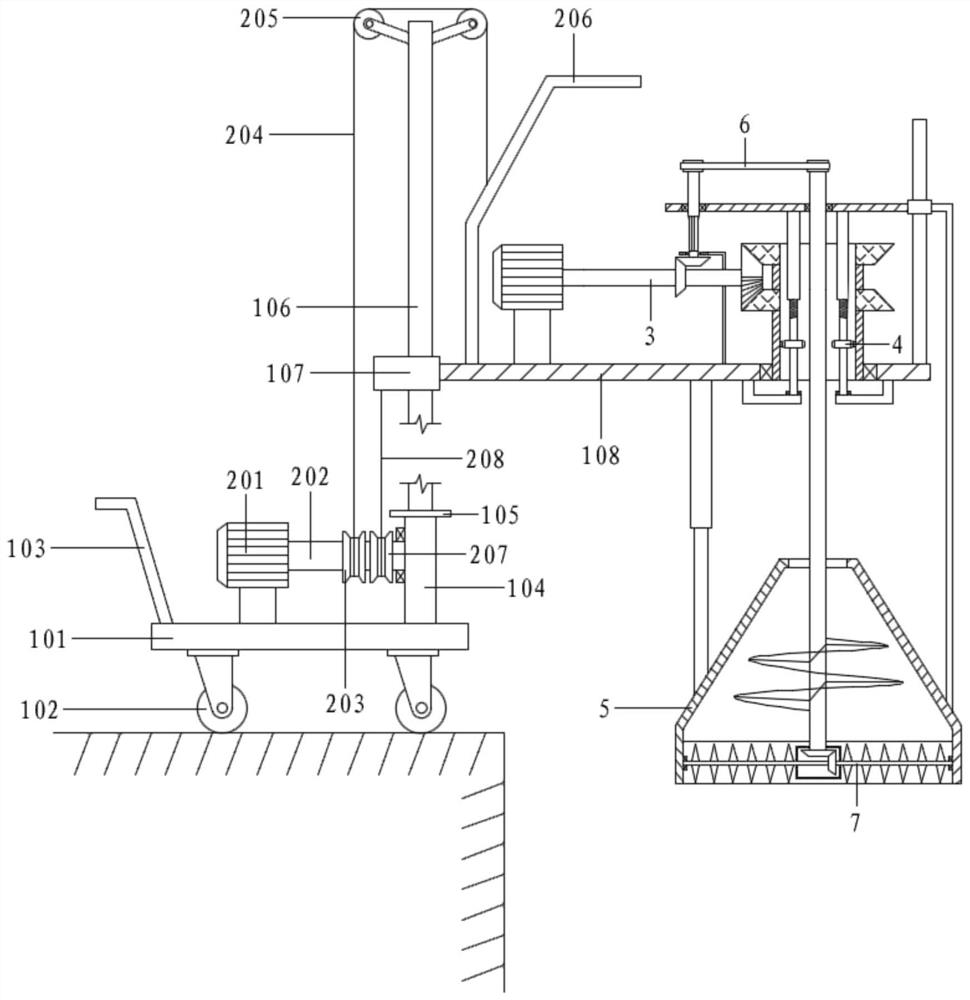

[0072] With reference to the accompanying drawings, an environmentally-friendly dredging vehicle with anti-clogging type for river channels includes a vehicle body assembly 1, a lifting assembly 2, a power assembly 3, a reciprocating assembly 4, a cover assembly 5, a negative pressure assembly 6 and a crushing assembly 7;

[0073] The car body assembly 1 includes a car plate 101, wheels 102, handlebars 103, a No. 1 support plate 104, a fixed plate 105, a No. 1 sliding rod 106, a No. 1 sliding sleeve 107 and a No. 2 support plate 108; the bottom of the car plate 101 is installed Wheel 102, a handlebar 103 is connected to the left side of the car plate 101; a support plate 104 is fixed to the car plate 101, a fixing plate 105 is fixed to the top of the first support plate 104, and a sliding rod 106 is fixed to the fixing plate 105 , The No. 1 sliding rod 106 is covered with a No. 1 sliding sleeve 107, and the right side of the No. 1 sliding sleeve 107 is connected with a No. 2 suppo...

Embodiment 3

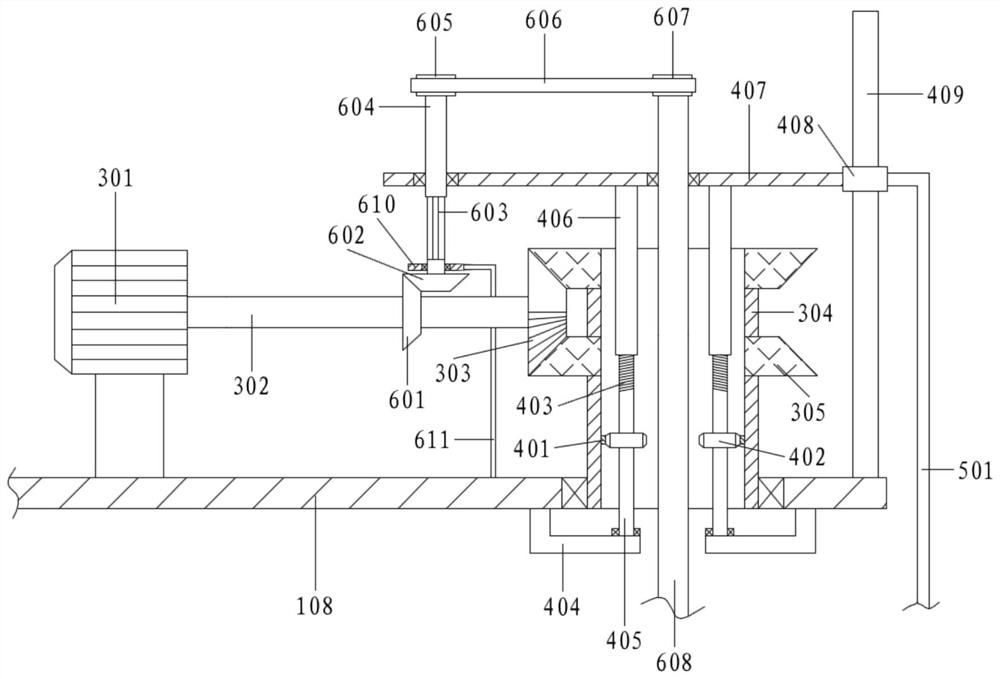

[0098] On the basis of Example 2,

[0099] It also includes a silt suction assembly 8; the silt suction assembly 8 includes a crankshaft 801, a sleeve 802, a piston rod 803, a piston plate 804, a piston barrel 805, a silt drainage pipe 806, a silt guide pipe 807, a type joint 808, and a rigid pipe 809 , The second connecting rod 810, the second type joint 811 and the suction hole 812;

[0100] The second rotating shaft 302 is connected with a crankshaft 801, and a sleeve 802 is installed on the crankshaft 801; a piston cylinder 805 is fixed on the mounting frame 206, and the piston cylinder 805 is equipped with a piston plate 804 that moves up and down; the sleeve 802 is connected upward with a piston rod 803, The piston rod 803 extends upward into the piston cylinder 805 and is hinged to the piston plate 804; the top of the piston cylinder 805 is connected with a silt discharge pipe 806, and the silt discharge pipe 806 is equipped with a one-way valve for controlling the sludge di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com