nbse 2 Research method of tribological properties of single crystal as solid lubricant for electrical contact

An electrical contact solid, tribological technology, applied in lubricating compositions, additives, scientific instruments, etc., can solve problems such as high requirements and low output, and achieve the effects of no equipment requirements, quick results, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0060] NbSe 2 A method for researching tribological properties of a single crystal as an electrical contact solid lubricant, comprising the following steps,

[0061] S1: Using NbSe 2 Single crystal preparation of NbSe 2 layer;

[0062] Specifically, the top-down mechanical exfoliation method was used to prepare NbSe 2 layer, specifically: take NbSe 2 Single wafer, peel off repeatedly with mechanical peeling tape, stick it on the cleaned copper surface, let it stand for 24 hours, tear off the tape, and get NbSe 2 layer.

[0063] S2: Research on NbSe 2 Layer surface features;

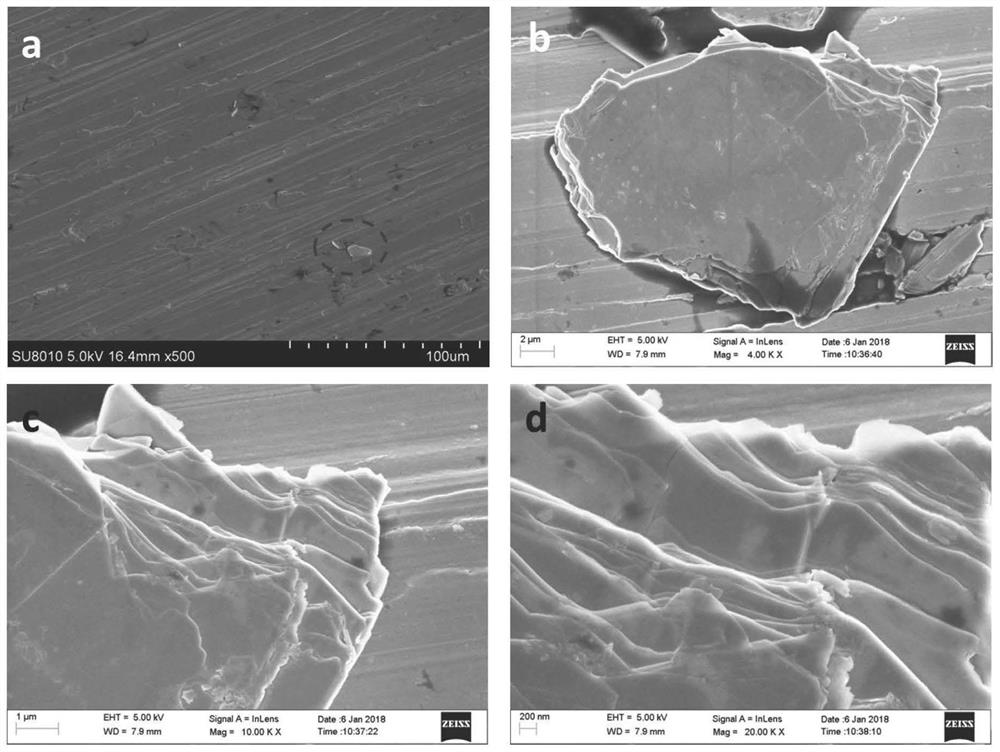

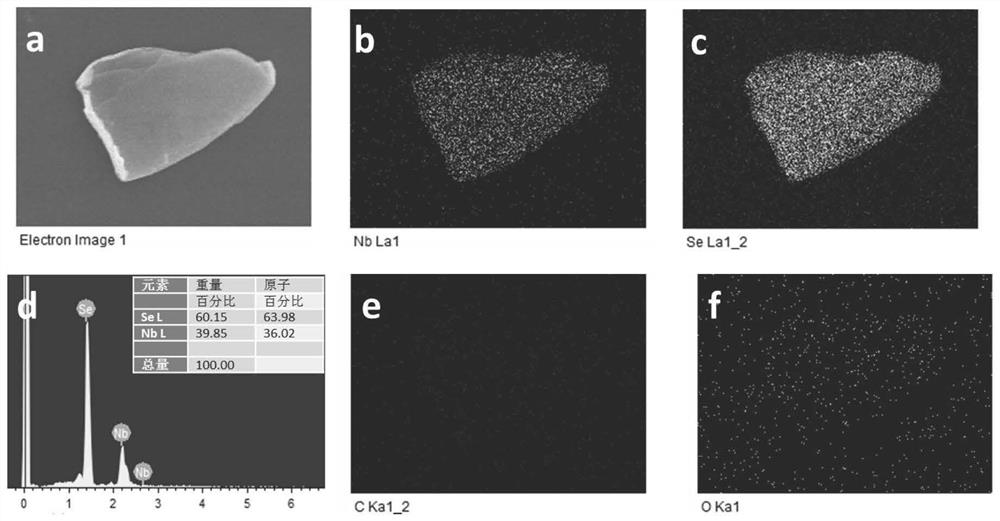

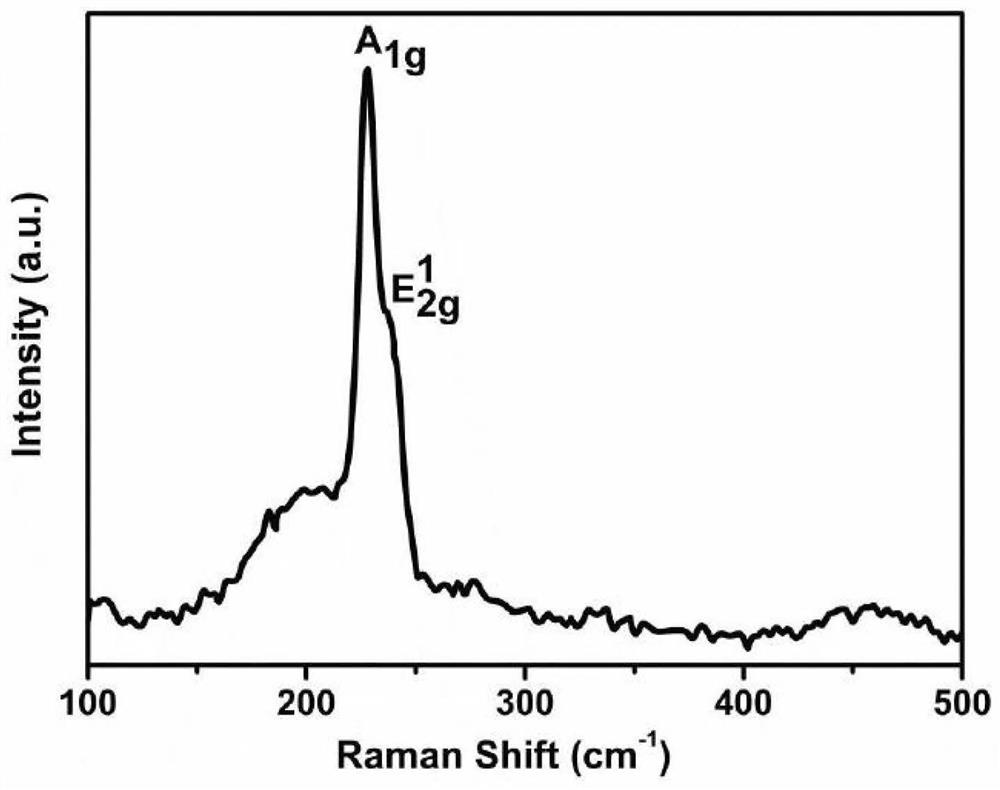

[0064] Specifically, the NbSe prepared by the top-down mechanical exfoliation method 2 The SEM image of the layer is attached figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com