A small mechanical mobile hoisting device for construction transportation

A technology for mechanical moving and lifting devices, applied in hoisting devices, hoisting devices, spring mechanisms, etc., can solve problems such as unstable operation and complex structure, and achieve stable, convenient operation, and easy maintenance and repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

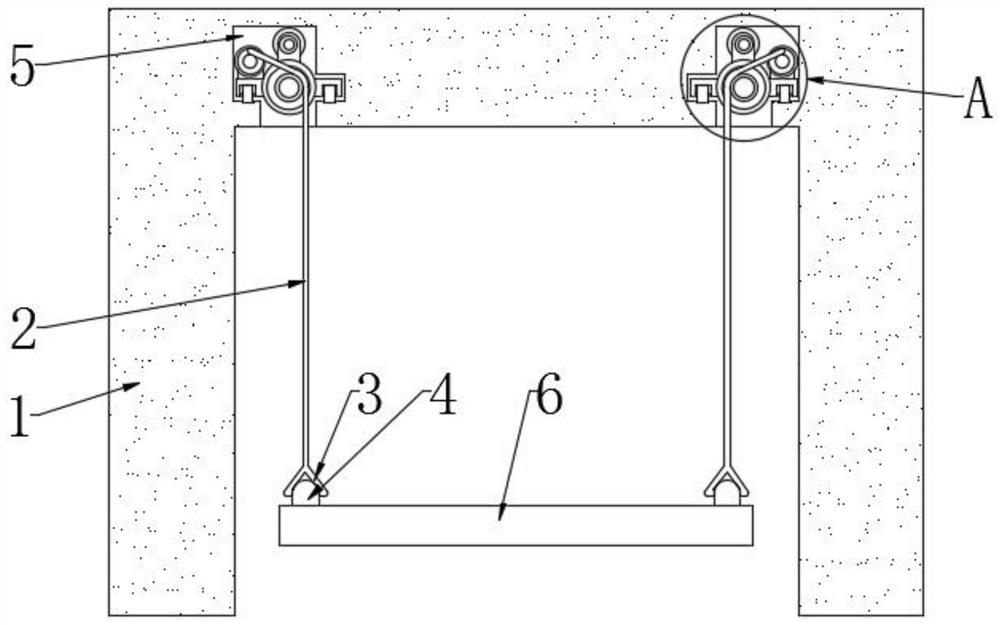

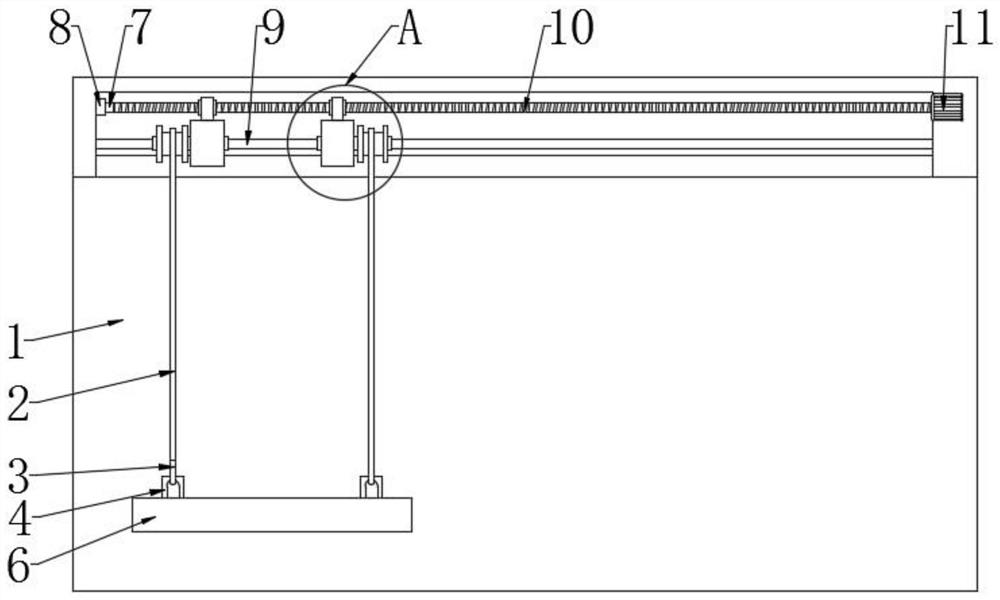

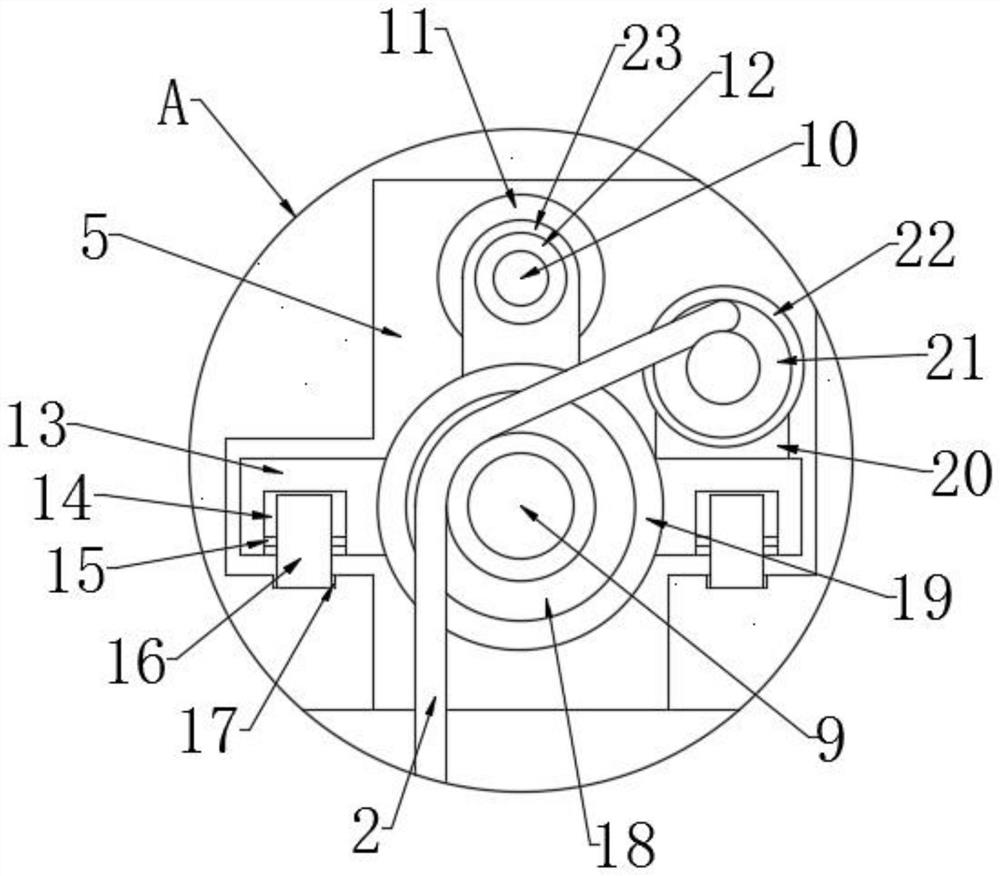

[0022] see Figure 1-4 , the present invention provides the following technical solutions: a small mechanical mobile hoisting device for construction transportation, comprising a main frame 1, characterized in that: the inside of the main frame 1 is provided with a cavity 5, and the inside of the cavity 5 is fixed A bearing 8 and a sliding rod 9 are connected, one end of the sliding rod 9 is fixedly connected to the surface of the main frame 1, a rotating shaft 7 is sleeved inside the bearing 8, and a threaded column 10 is fixedly connected to one end of the rotating shaft 7, By arranging the threaded post 10 and the slide bar 9, in practical applications, the stability of the support plate 6 during the movement can be ensured, thus ensuring the safe use of the device. One end of the threaded post 10 is fixedly connected with a first motor 11. The first motor 11 is fixedly connected inside the main frame 1, the surface of the threaded column 10 is sleeved with a threaded pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com