S-shaped edible mushroom bar conveying vehicle

An edible fungus and wheel technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of affecting the survival rate of rod making, affecting the handling efficiency, and laborious pulling and pushing, so as to increase the wrapping property, improve the survival rate, increase the The effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

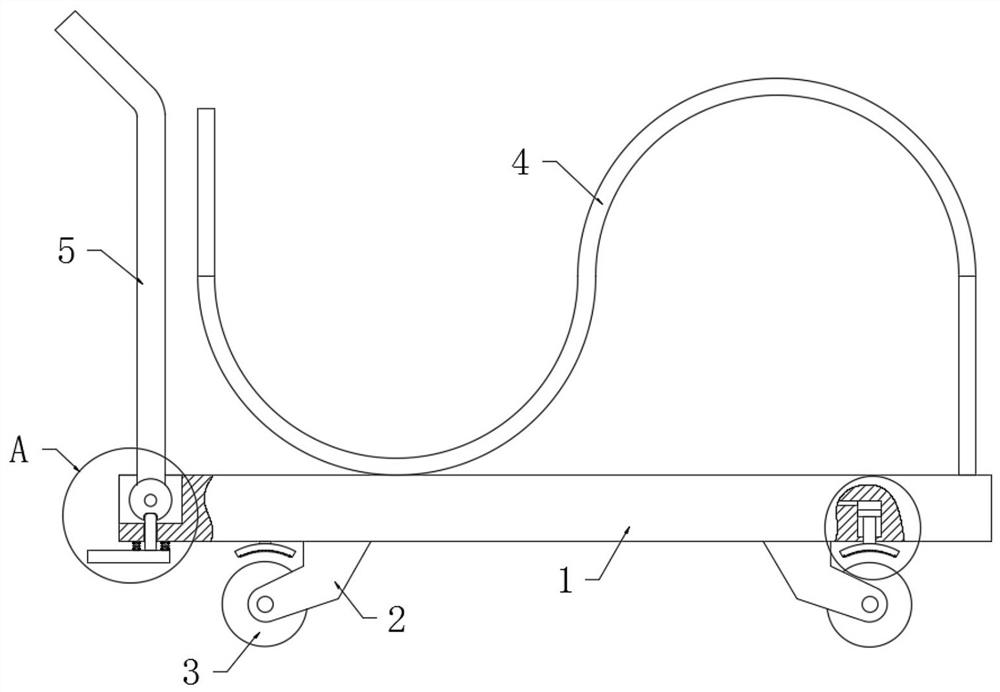

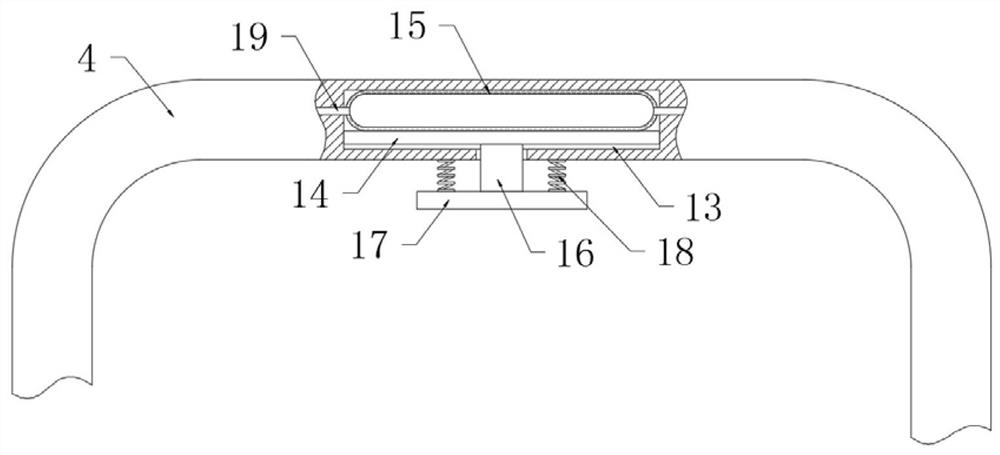

[0022] refer to Figure 1-4 , an S-shaped edible fungus transporter, comprising a base 1, four wheel bearings 2 are welded on the lower end of the base 1, a wheel 3 is connected to the lower end of each wheel bearing 2 through bearing rotation, and a wheel 3 is fixedly connected to the base 1 An S-shaped structure of the frame plate 4, the width of the frame plate 4 is equal to the width of the base 1, and the frame plate is made of aluminum alloy material, which has the advantages of light weight and high strength.

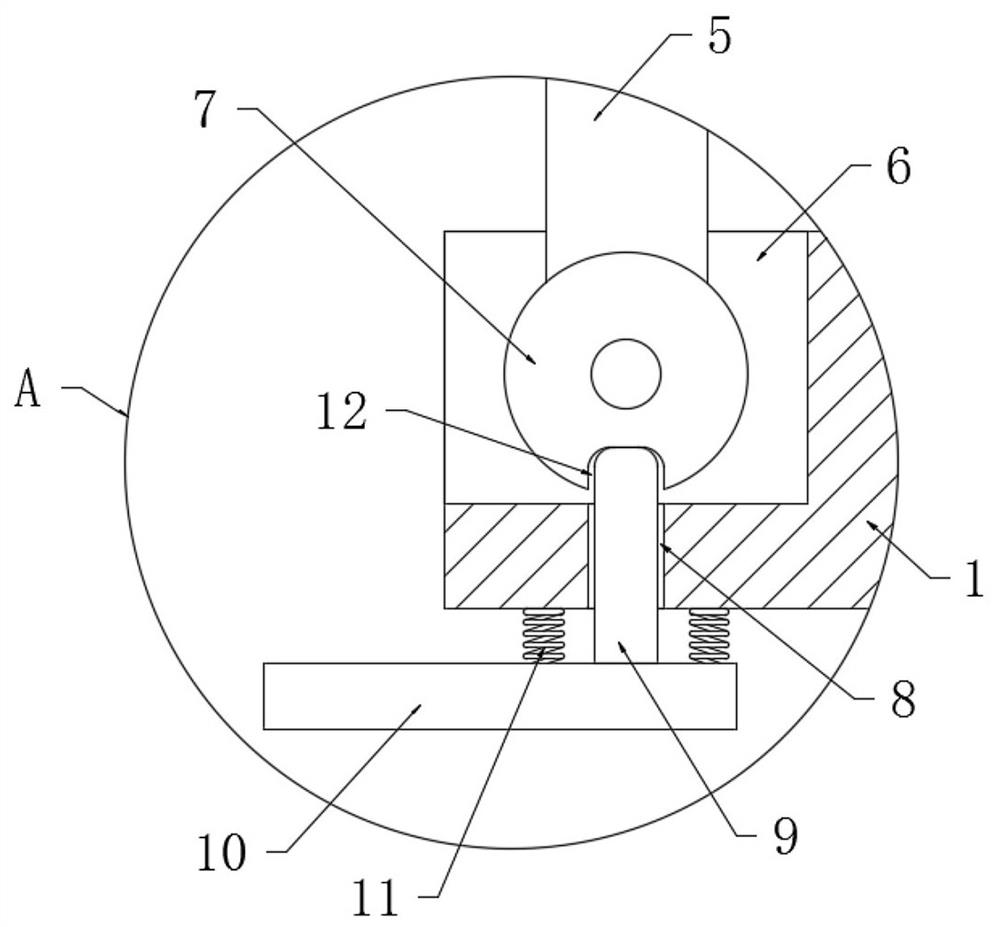

[0023] One side plate edge of base 1 is provided with rotatable handle device, and rotatable handle device comprises the handle 5 of U-shaped structure, and one end of base 1 is provided with two rotating grooves 6, and the groove wall on both sides of each rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com