Welding seam welding device used by being based on wind energy motor unit protection shell

A technology for protecting shells and welding devices, which is applied to auxiliary devices, welding equipment, auxiliary welding equipment, etc., and can solve problems such as difficult welding and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

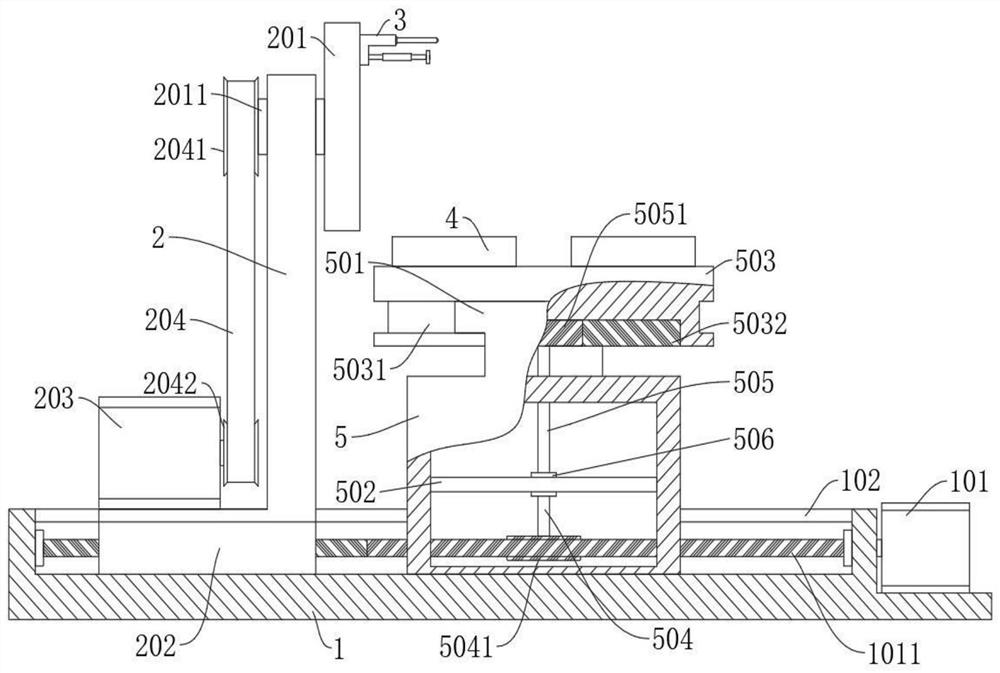

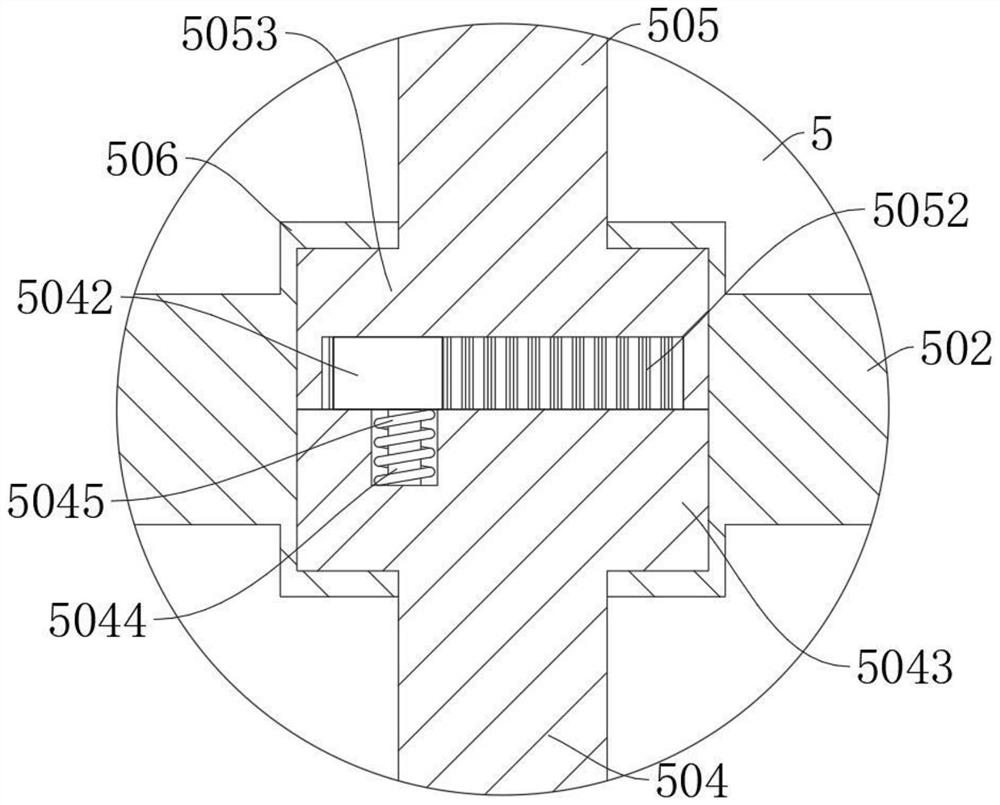

[0029] refer to figure 1 , image 3 and Figure 4, a seam welding device based on the protective shell of a wind energy generator, comprising a welding head 304, a three-jaw chuck 4, a base 1, a bracket 2 and a mounting seat 5 slidingly connected to the base 1, the bracket 2 and the mounting base 5 are fixedly connected with a first slider 202, the base 1 is provided with a first chute 102, the first slider 202 is slidably connected in the first chute 102, and the base 1 is fixedly connected with a first motor 101 , the output end of the first motor 101 extends to the first chute 102 and is fixedly connected with the worm 1011, the first slider 202 is provided with a worm thread hole matching the worm 1011, and the mounting seat 5 is rotatably connected with the first rotating shaft 504 and the second rotating shaft 505, one end of the first rotating shaft 504 is fixedly connected with the worm gear 5041 meshed with the worm 1011, the other end of the first rotating shaft 50...

Embodiment 2

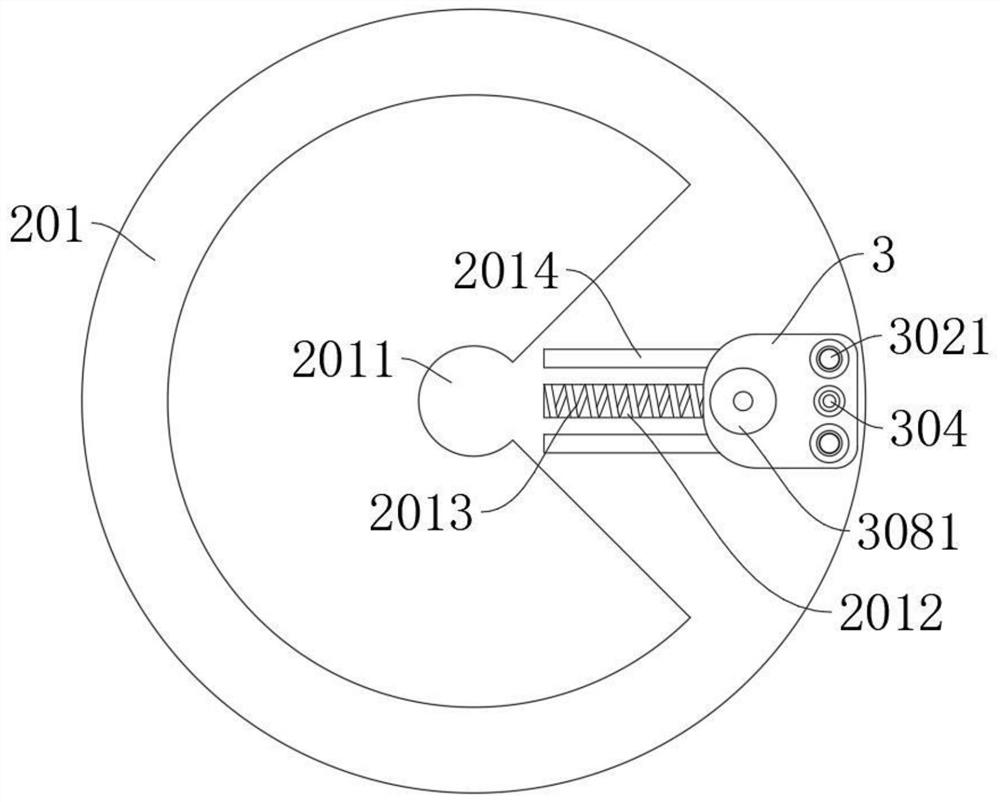

[0032] refer to Figure 3-5 , is basically the same as that of Embodiment 1, furthermore, the adjustment mechanism includes a first screw rod 307 and a second screw rod 308, the first screw rod 307 is screwed with the second screw rod 308 through a threaded sleeve 3072, and the first screw rod 307 is fixedly connected with a third sliding block 3071, the working head 3 is provided with a third chute 306, the third sliding block 3071 is slidably connected in the third chute 306, and the end of the second screw rod 308 away from the threaded sleeve 3072 is rotatably connected There is a roller 3081, the working head 3 is fixedly connected with a second slider 3011, the second slider 3011 is slidably connected in the second chute 2012, the first spring 2013 is offset against the second slider 3011, and the working head 3 is fixedly connected with a Auxiliary slider 3012, drive disc 201 is provided with auxiliary chute 2014, auxiliary slider 3012 is slidably connected in the auxil...

Embodiment 3

[0036] refer to figure 1 , is basically the same as Embodiment 1, furthermore, the driving part includes a second motor 203, the second motor 203 is fixedly connected on the support 2, the output end of the second motor 203 is fixedly connected with a second pulley 2042, and the drive shaft 2011 is fixedly connected with a first pulley 2041 at one end away from the drive disc 201, and the first pulley 2041 and the second pulley 2042 are connected in rotation through the belt 204. Here, when the second motor 203 drives the drive disc 201 to rotate through the belt 204 , the belt 204 can preferably choose a gear belt with a precise transmission ratio, so as to ensure the stable movement of the welding head 304 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com