100% grape juice and production method thereof

A production method and technology for grape juice, applied in the field of beverage products, can solve the problems of lack of aroma of grape juice, poor sensory quality, thin taste, etc., and achieve the effect of rich and fragrant overall taste, saving of processing raw materials, and rich and natural aroma of grapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

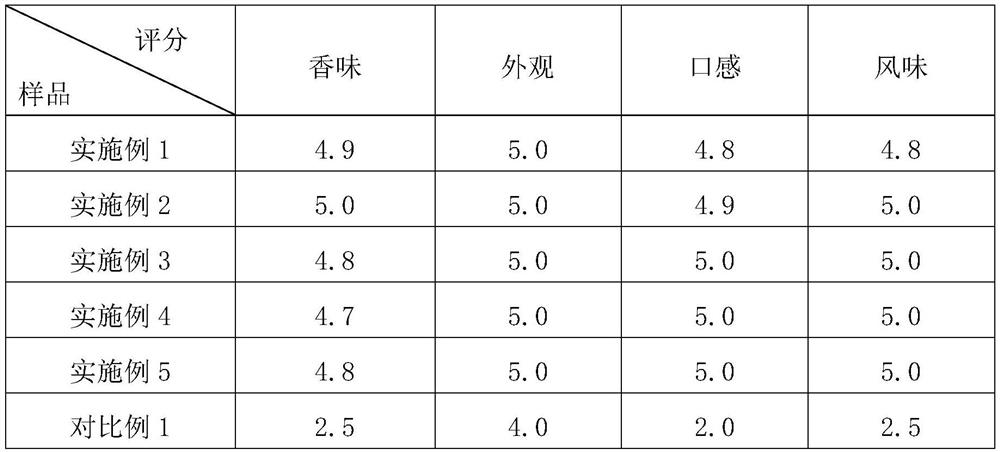

Embodiment 1

[0026] Follow the steps below to prepare 100% grape juice:

[0027] Step 1) Select suitable varieties of fresh grape fruit bunches, first put the fresh grape fruit bunches into flowing clear water to rinse for 40 seconds, then soak the washed grape fresh fruit bunches in 0.1% TD powder aqueous solution for bubble cleaning for 30 minutes. Then the fresh grape fruit bunches after air bubble cleaning are rinsed with clear water to complete the cleaning work, and then the stems on the fresh grape fruit bunches are removed to obtain grape fruit particles; in this example, the grape fruit Grains are composed of 80% summer black grapes, 5% kyoho grapes and 15% jasmine grapes;

[0028] Step 2) Carry out the primary extraction and primary filtration treatment of the grape fruit in sequence with a filter mesh number of 60 to obtain the separated grape juice A and peel and meat scraps (without grape seeds); then the obtained grape juice A is stored in in a temporary storage container fo...

Embodiment 2

[0034] Follow the steps below to prepare 100% grape juice:

[0035] Step 1) Select the fresh grape fruit bunches of suitable varieties, put the fresh grape fruit bunches into flowing clear water and rinse them for 50 seconds, then soak the fresh grape fruit bunches after washing in 0.2% TD powder aqueous solution for 25 minutes, and press them tightly. Then the fresh grape fruit bunches after air bubble cleaning are rinsed with clear water to complete the cleaning work, and then the stems on the fresh grape fruit bunches are removed to obtain grape fruit particles; in this example, the grape fruit Grains are composed of 80% summer black grapes, 10% Kyoho grapes and 10% jasmine grapes;

[0036] Step 2) Carry out the primary extraction and primary filtration of the grape fruit in sequence with a filter mesh number of 50 to obtain separated grape juice A and peel meat scraps (without grape seeds); subsequently, the obtained grape juice A is stored in in a temporary storage conta...

Embodiment 3

[0042] Follow the steps below to prepare 100% grape juice:

[0043] Step 1) Select the fresh grape fruit bunches of suitable varieties, put the fresh grape fruit bunches into flowing clear water and rinse them for 60 seconds, then soak the fresh grape fruit bunches after washing in 0.3% TD powder aqueous solution for 25 minutes, then press them tightly. Then the fresh grape fruit bunches after air bubble cleaning are rinsed with clear water to complete the cleaning work, and then the stems on the fresh grape fruit bunches are removed to obtain grape fruit particles; in this example, the grape fruit Grains are composed of 65% summer black grapes, 15% Kyoho grapes and 20% Jasmine grapes;

[0044]Step 2) Carry out the primary extraction and primary filtration of the grape fruit in sequence with a filter mesh number of 70 to obtain the separated grape juice A and peel and meat scraps (without grape seeds); then the obtained grape juice A is stored in in a temporary storage contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com