Quality inspection device for white spirit production line

A technology of production line and liquor, which is applied to detect the appearance of fluid at the leakage point, manipulator, chuck and other directions, can solve the problems of wasting manpower, low efficiency, and leakage is not easy to find, so as to improve work efficiency, improve detection quality, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

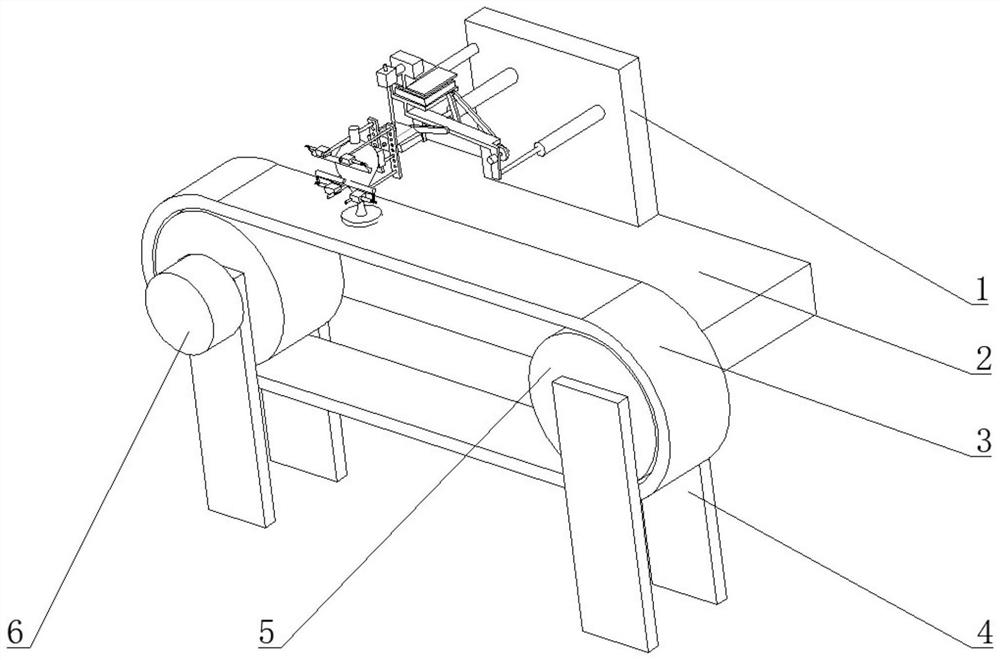

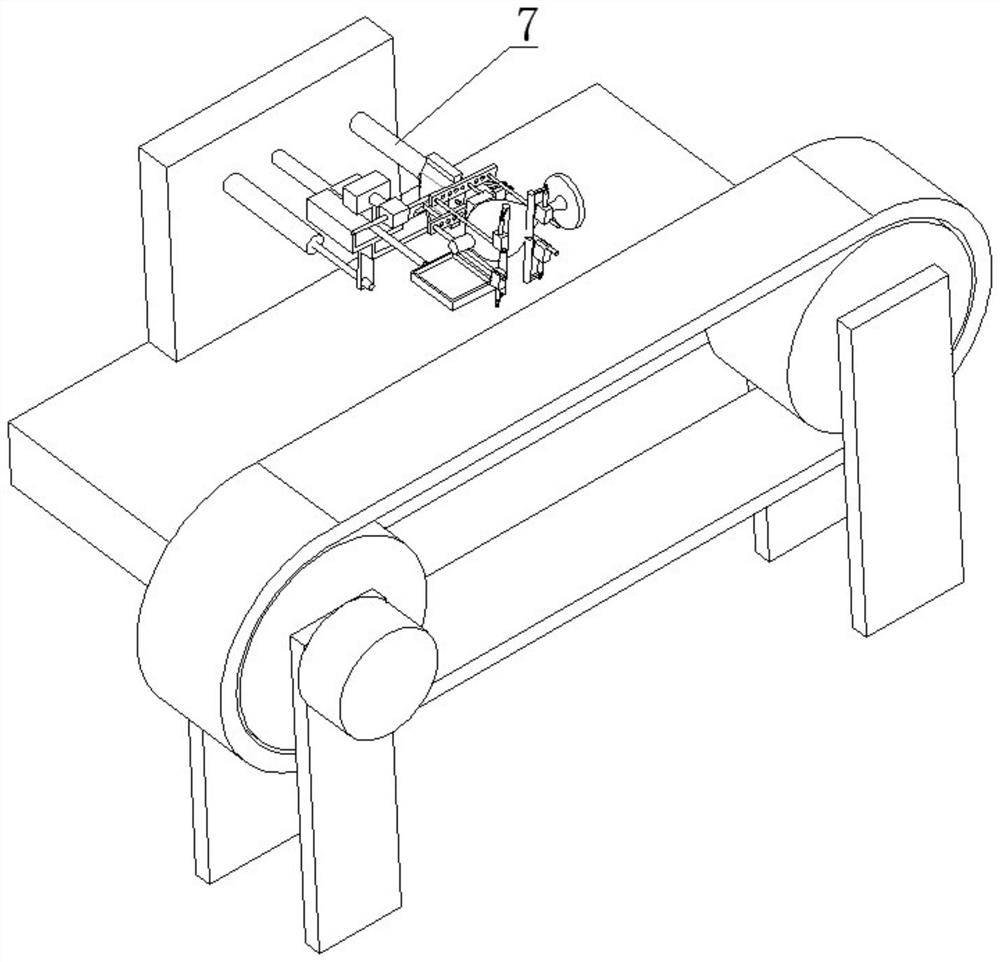

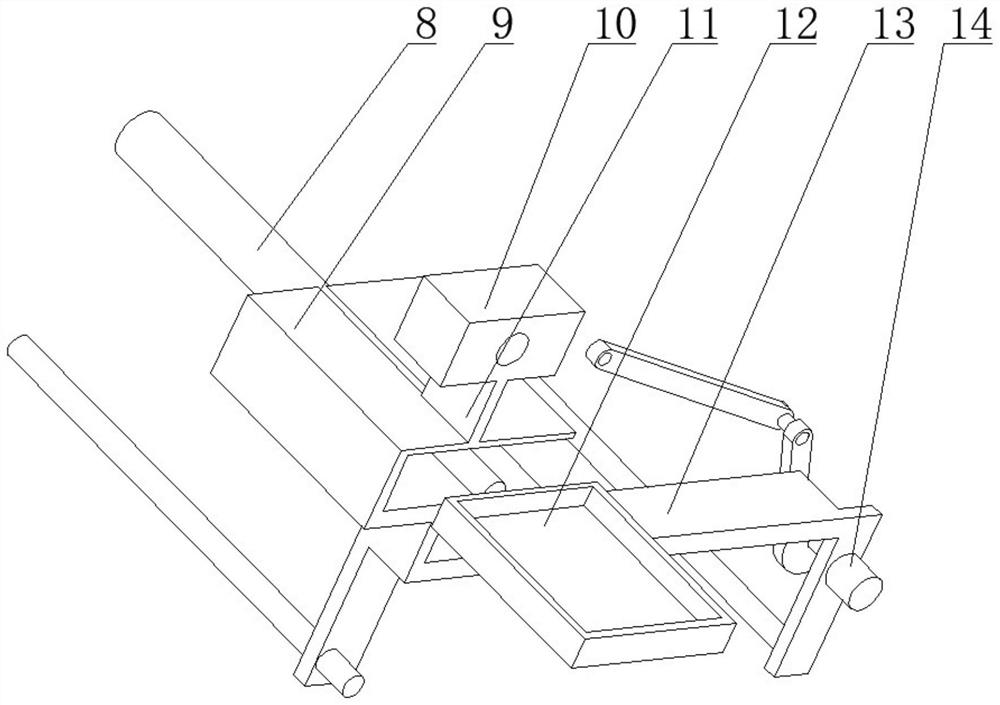

[0029] like Figure 1-Figure 6 As shown, the present invention includes two sets of symmetrical risers 4, one set of symmetrical risers 4 is fixedly connected to a motor one 6, and the output shaft of the motor one 6 passes through a set of symmetrical vertical risers. One of the plates two 4, the output shaft of the motor one 6 is fixedly connected to one end of the central shaft of a runner 5, and the other end bearing of the central shaft of one runner 5 is connected to a group of symmetrical vertical plates two 4 Wherein the other one, another set of symmetrical vertical plates 2 4 are respectively bearing connected to the central axis of the other runner 5, and the two ends of the conveyor belt 3 respectively surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com