A Construction Method for Reverse Obstacle Clearance of Pipe Jacking

A construction method and a technology for clearing obstacles, which can be applied to earth-moving drilling, shaft equipment, wellbore lining, etc., and can solve problems such as unfavorable ground pipe jacking construction operations and soil changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings.

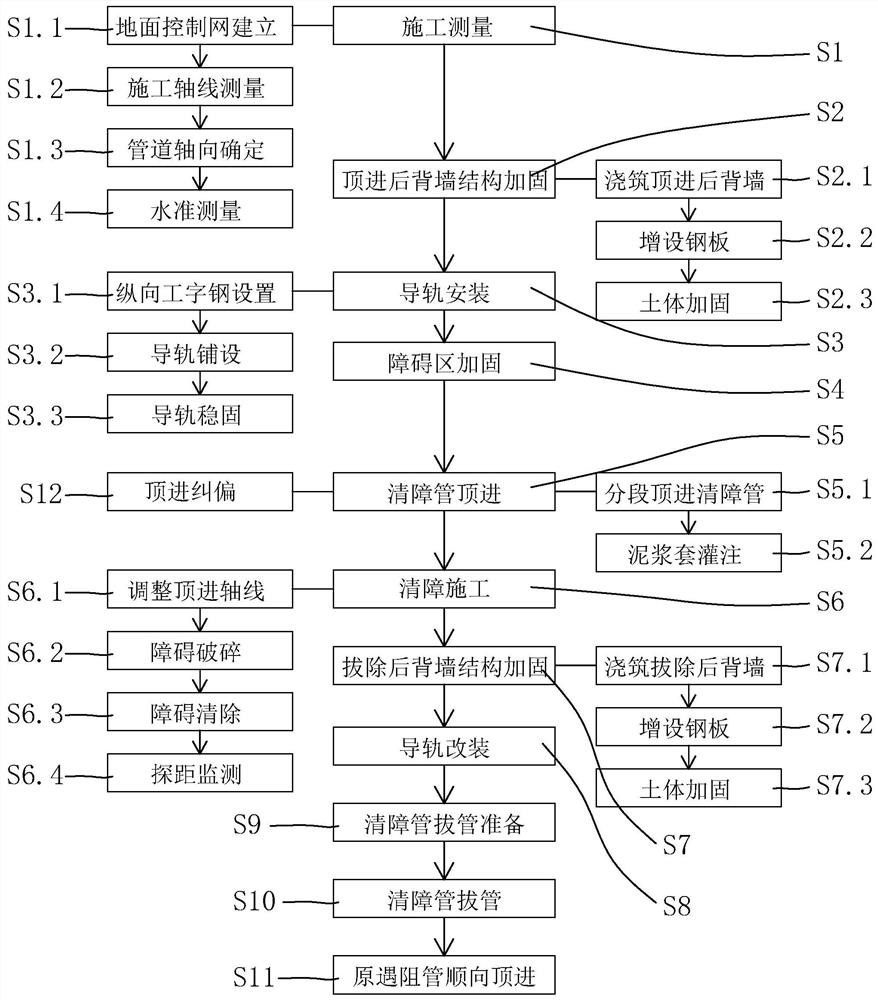

[0077] Such as figure 1 As shown, the present invention discloses a construction method for reverse obstacle removal of pipe jacking, including S1 construction measurement, S2 jacking back structure reinforcement, S3 guide rail installation, S4 obstacle area reinforcement, S5 obstacle removal pipe jacking, S6 clearing Barrier construction, S7 back wall structure reinforcement after removal, S8 guide rail modification, S9 removal of removal pipe preparation, S10 removal of removal pipe, S11 jacking of original blocking pipe jacking, S12 jacking correction and other construction steps.

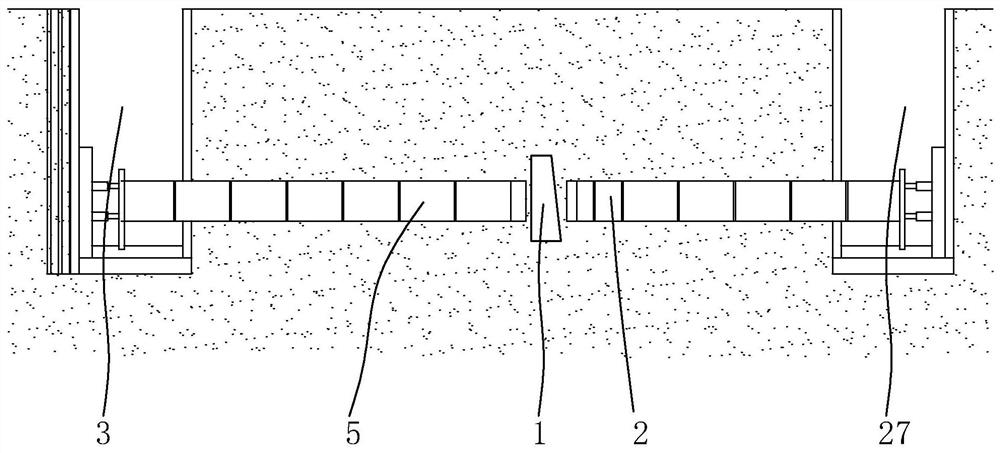

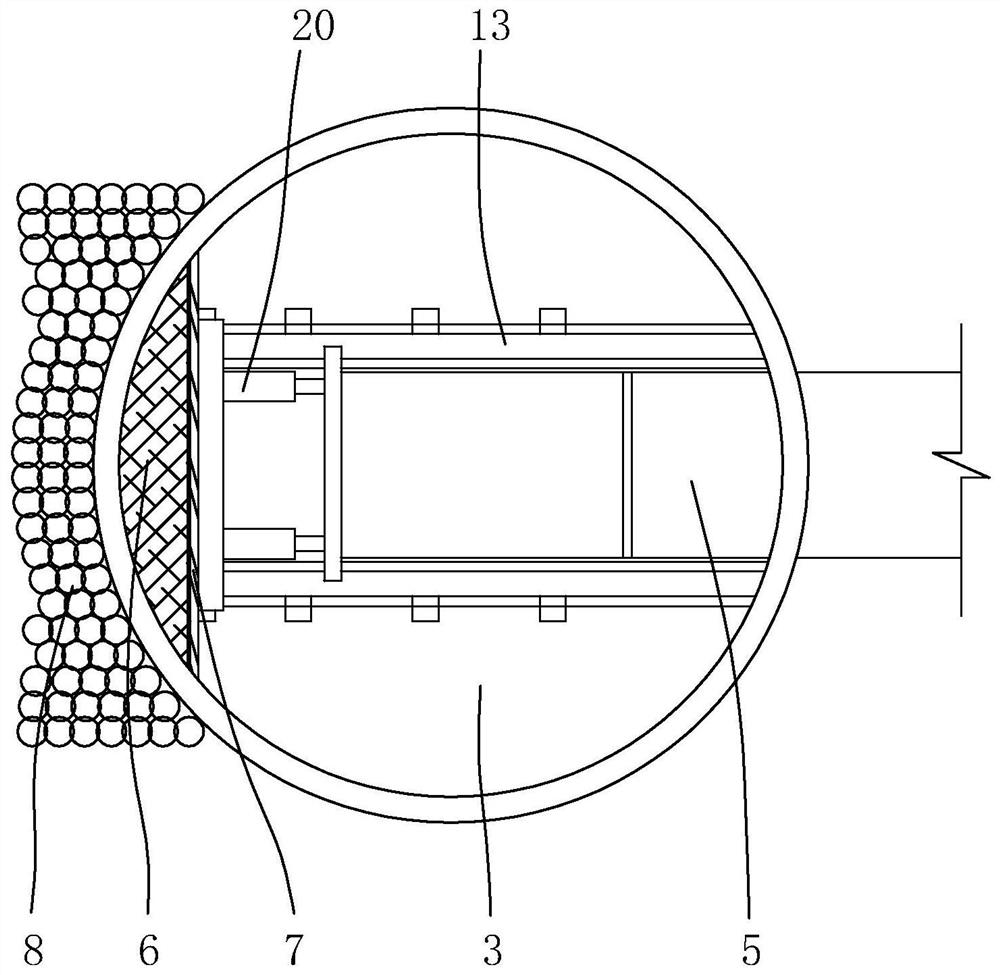

[0078] Such as figure 1 , figure 2 As shown, S1 construction measurement, according to the coordinates of the original obstructed jacking pipe 2, obstacle 1, working well 27, and receiving well 3, S1.1 Ground control network establishment, S1.2 Construction axis measurement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com