A storage tank and its design calculation method

A technology for reservoirs and ponds, which is applied in construction, infrastructure engineering, protection devices, etc., can solve the problems of cumbersome active anti-floating management, increased labor costs, and high foundation requirements, and achieves protection of groundwater resources, cost savings, and engineering volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

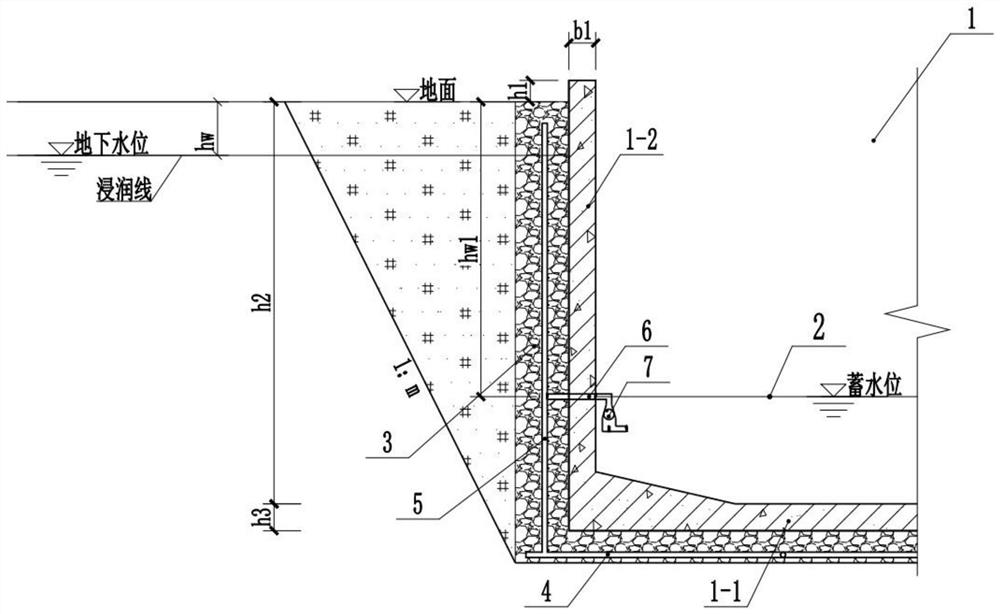

[0094] Step S02: Calculate the anti-floating stability safety factor K according to the load of the reservoir w When the requirements are met, the buried depth of the groundwater table outside the reservoir;

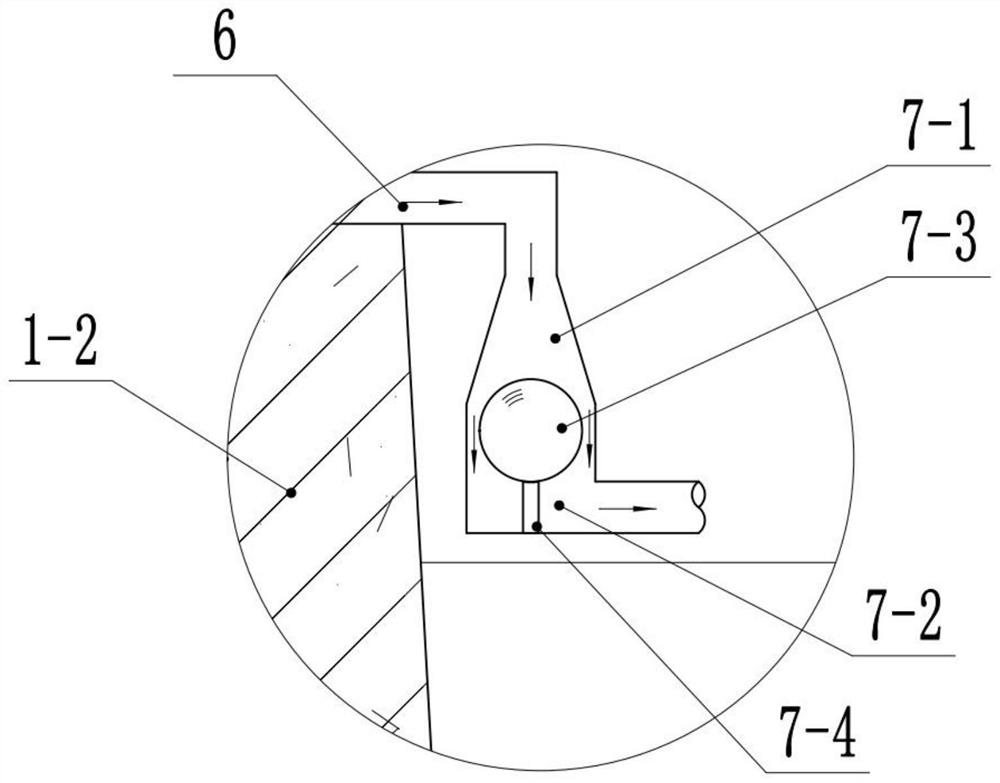

[0095] Step S03: determine the height of the seepage pipe 6 and the one-way valve 7 installed on the side wall of the reservoir;

[0096] According to the automatic drainage and anti-floating method of the present invention, instead of making plain concrete counterweight, the method of lowering the groundwater level is used to calculate the minimum buried depth h of the groundwater level w1 , which is the installation height of the first layer of seepage pipe, such as figure 1 and figure 2 shown.

[0097] Buoyancy value N w,k Calculated as follows:

[0098] N w,k =A 1 ·(h 2 + h 3 -h w1 )·γ w

[0099] Calculate N w,k =7560-1890h w1

[0100] Depend on have to

[0101] get h w1 ≥2.67m.

[0102] In order to ensure that the anti-floating requirements ar...

Embodiment 2

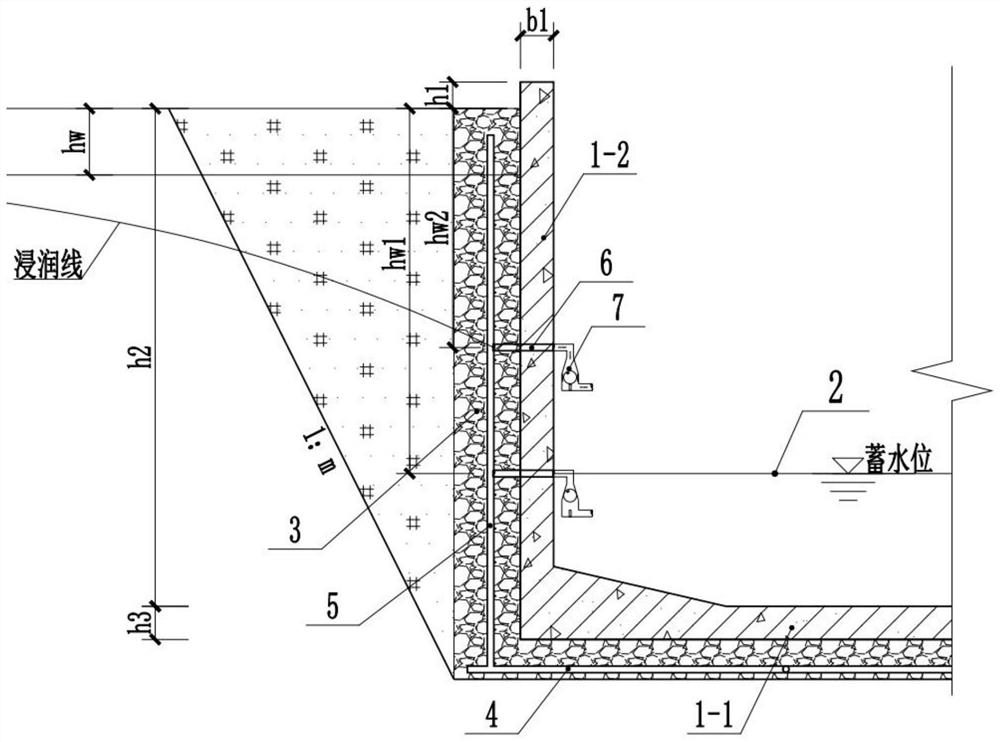

[0135] Step S06: Calculate the anti-floating stability safety factor K when the one-way valve 7 is closed w Whether the requirements are met, if yes, then execute step S07; if not, then repeat step S02 to step S06;

[0136] When the water level in the pool exceeds the installation height of the first layer of check valve 7, the first layer of check valve 7 is closed now, and the groundwater level outside the pool near the reservoir begins to rise. The water storage level 2 in the pool is considered to be consistent with the installation height of the one-way valve 7, and the groundwater level outside the pool near the reservoir is considered to be buried in the same depth as the original groundwater level (the most unfavorable case), and the anti-floating stability at this time is calculated, as image 3 shown.

[0137] At this time, by

[0138] Anti-floating stability does not meet the requirements, so it is required to install a second layer of drainage pipe.

[0139] W...

Embodiment 3

[0155] When the water level in the pool exceeds the installation height of the second layer of check valve 7, the two layers of check valve 7 are closed now, and the groundwater level outside the pool near the reservoir begins to rise. The water storage level 2 in the pool is considered to be consistent with the installation height of the second-layer one-way valve 7, and the groundwater level outside the pool near the reservoir is considered to be buried in the same depth as the original groundwater level (the most unfavorable case), and the anti-floating stability at this time is calculated. like Figure 5 shown.

[0156] At this time, by

[0157] Anti-floating stability does not meet the requirements, so a third layer of drainage pipe 6 is required.

[0158] When the water level in the pool exceeds the installation height of the second layer of check valve 7, the lower two layers of check valve 7 are all closed this moment. The water level in the pond is considered by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com