Electroslag remelting equipment for ultra-long steel ingot

A technology of electroslag remelting and steel ingots, which is applied in the field of electroslag remelting equipment for ultra-long steel ingots, can solve problems such as fatigue, and achieve the effect of accelerating forming speed and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

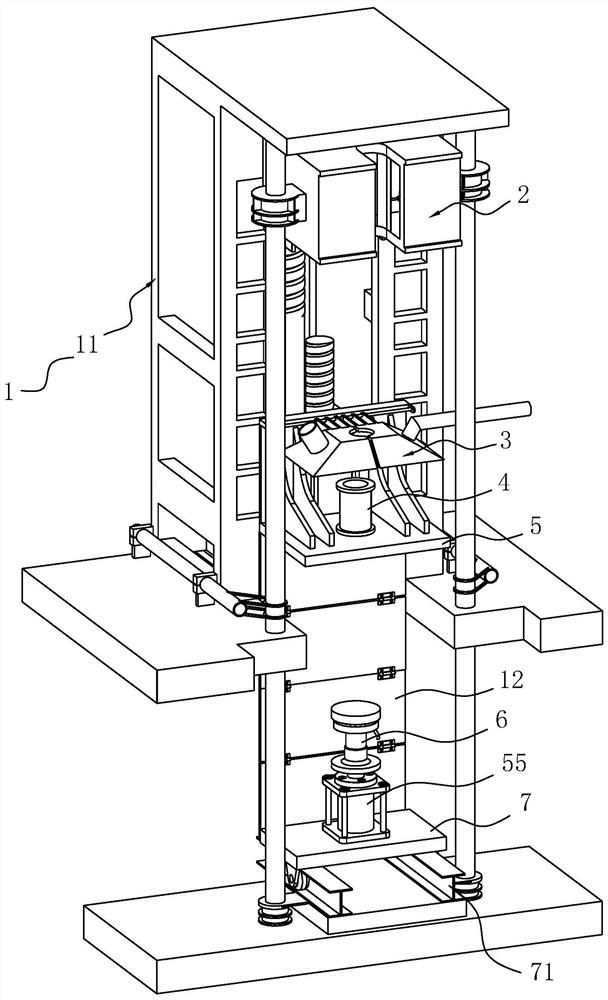

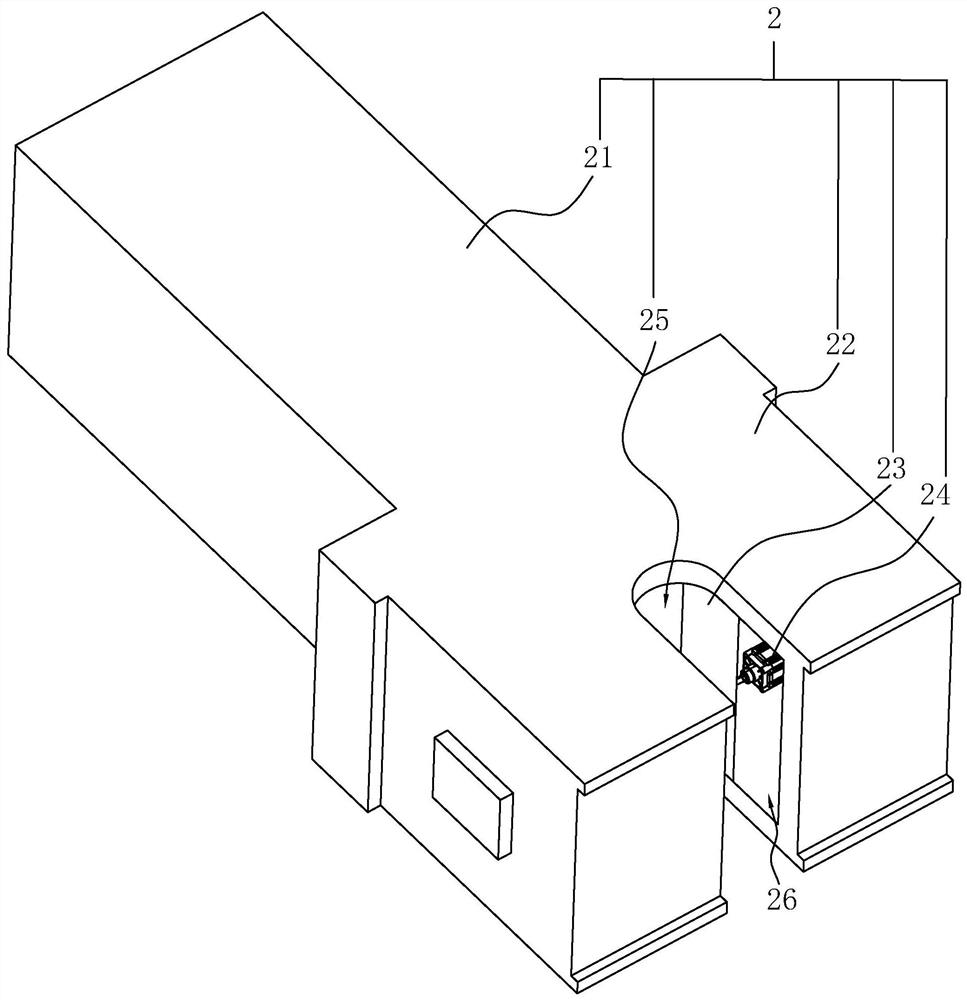

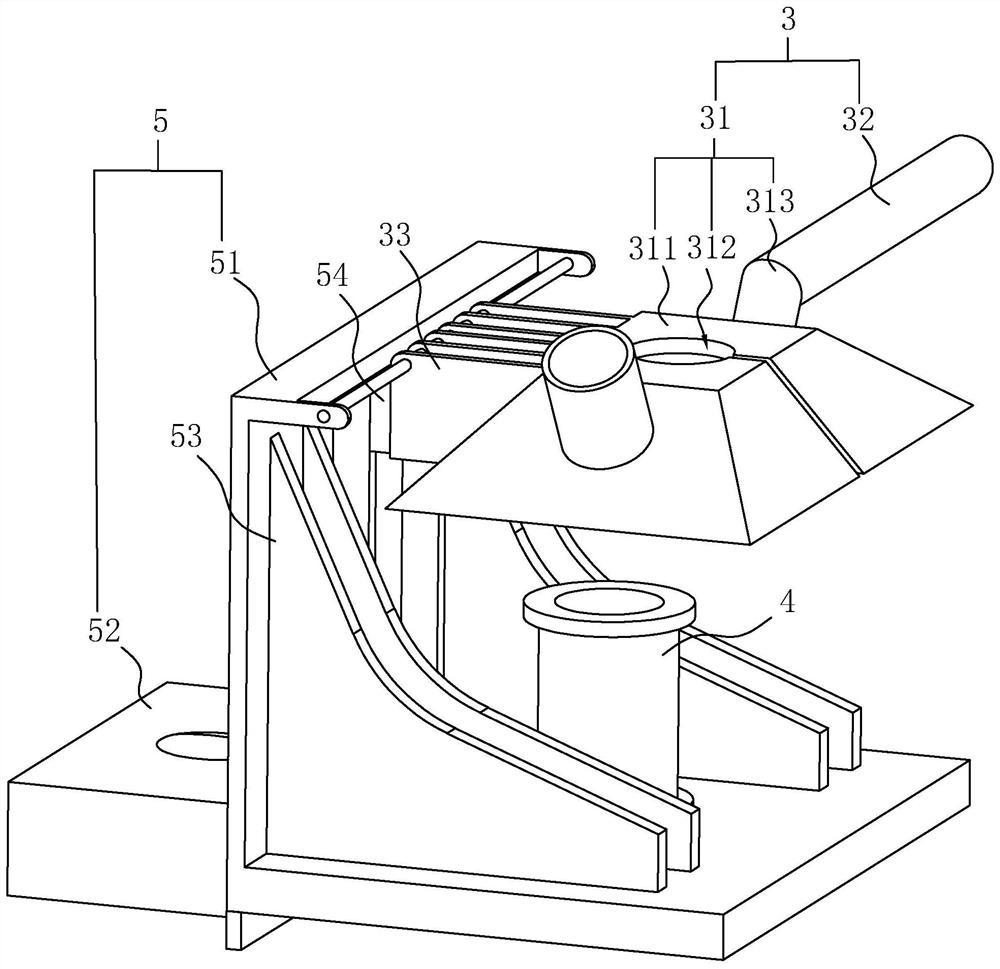

[0032] refer to figure 1, is an electroslag remelting equipment for ultra-long steel ingots disclosed in the present invention, including a frame 1 standing vertically on the ground, and the frame 1 in this embodiment includes a gantry 11 . A jig 2 for clamping the dummy electrode is slidably connected to the frame 1 along the vertical direction, a mobile platform 5 is slidably connected to the frame 1 below the jig 2 along the vertical direction, and a mobile platform 5 is fixedly connected to the dummy electrode. For the slag remelting crystallizer 4, the mobile platform 5 is also equipped with a suction assembly 3 for collecting the delay generated during the electroslag remelting process, and the suction assembly 3 is located above the top port of the crystallizer 4. There is a deep pit directly below the crystallizer 4, and a horizontally arranged slide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap