Production method of p-nitrophenol

A production method and a technology for p-nitrophenol are applied in the production field of p-nitrophenol, and can solve the problems of errors in the cooling crystallization process, low automation level, poor product quality, etc., so as to reduce energy consumption and production costs, improve purity and Yield, effect of reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

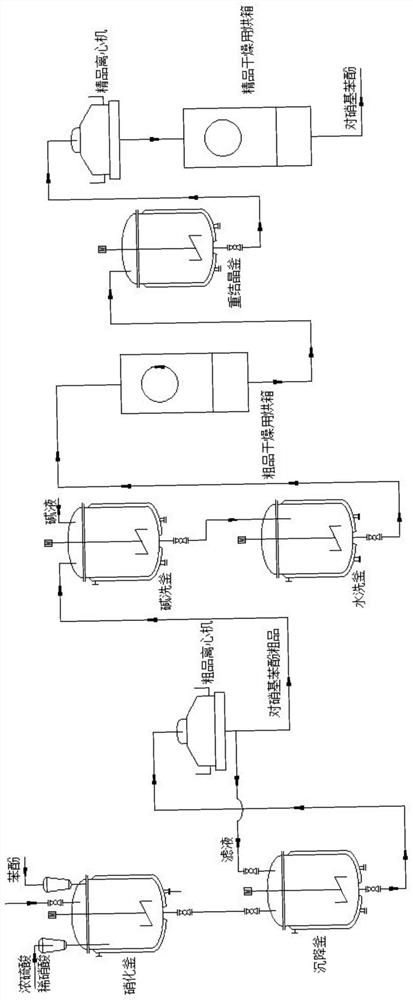

[0024] Such as figure 1 Shown, a kind of production method of p-nitrophenol, production method is based on the production system of p-nitrophenol, and production system comprises the nitration tank that is arranged on the front end, and the downstream of nitration tank is provided with settling tank and crude product centrifuge, settling tank And the downstream of the centrifuge is provided with an alkali cleaning kettle, the downstream of the alkali cleaning kettle is provided with a washing kettle, the downstream of the water washing kettle is provided with an oven for drying the crude product, and the downstream of the drying oven for the crude product is provided with a recrystallization kettle, and the downstream of the recrystallization kettle is arranged There are high-quality centrifuges and high-quality drying ovens;

[0025] The production method includes the following steps:

[0026] 1). Nitrification: transfer phenol to phenol spray tank, heat up to 80°C, mix conc...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is:

[0040]A production method of p-nitrophenol, the production method is based on the production system of p-nitrophenol, the production system includes a nitration tank arranged at the front end, a settling tank and a crude product centrifuge are arranged downstream of the nitration tank, the settling tank and the centrifuge The downstream of the alkali washing kettle is provided with an alkali washing kettle, the downstream of the alkali washing kettle is provided with a washing kettle, the downstream of the water washing kettle is provided with an oven for drying crude products, the downstream of the drying oven for crude products is provided with a recrystallization kettle, and the downstream of the recrystallization kettle is provided with a fine centrifugal Machine and fine drying oven;

[0041] The production method includes the following steps:

[0042] 1). Nitrification: transfer phenol to phenol spray ...

Embodiment 3

[0054] The difference between this embodiment and embodiment 1, 2 is:

[0055] A production method of p-nitrophenol, the production method is based on the production system of p-nitrophenol, the production system includes a nitration tank arranged at the front end, a settling tank and a crude product centrifuge are arranged downstream of the nitration tank, the settling tank and the centrifuge The downstream of the alkali washing kettle is provided with an alkali washing kettle, the downstream of the alkali washing kettle is provided with a washing kettle, the downstream of the water washing kettle is provided with an oven for drying crude products, the downstream of the drying oven for crude products is provided with a recrystallization kettle, and the downstream of the recrystallization kettle is provided with a fine centrifugal Machine and fine drying oven;

[0056] The production method includes the following steps:

[0057] 1). Nitrification: transfer phenol to phenol sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com