A follow-up inkjet printer

A kind of inkjet printer and inkjet technology, which is applied in the field of inkjet printers, can solve the problems of unrecognizable two-dimensional codes, different inkjet positions, and different inkjet sizes, so as to prevent different inkjet positions, avoid left and right movement, Prevent the effect of unclear coding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

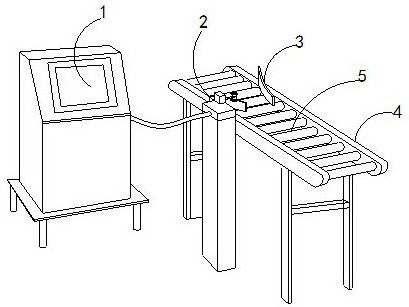

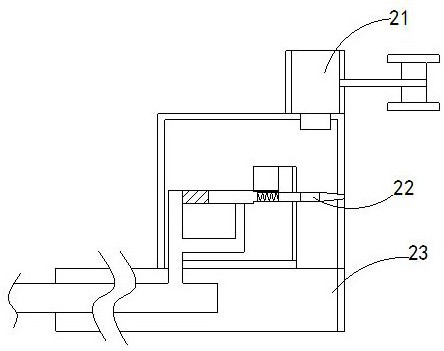

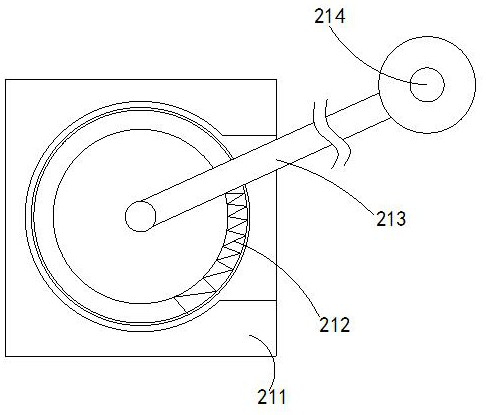

[0023] Such as Figure 1 - Figure 5 Down:

[0024] One way of flowing a spraying machine includes a control device 1, a coding apparatus 2, a guide plate 3, a fixing frame 4, a roller 5, and the control device 1 connected to the inkjet device 2, the guidance. The plate 3 is mounted on the upper end of the roller 5, the roller 5 being embodied inside the fixing frame 4, and the inkjet apparatus 2 is provided with a stabilizing mechanism 21, an injector 22, a fixing plate 23, and the fixing plate 23. The left end is connected to the control device 1, and the stabilizing mechanism 21 is mounted on the upper end of the injector 22, the injector 22 is welded to the upper end of the fixing plate 23 and the interior is conducted, the left side and control of the fixing plate 23. The device 1 conducts a pipe connection, and the inner portion of the injector 22 is provided with a hydraulic pump and a jet nozzle, and the nozzle direction is the right side of the injector 22, and the product...

Embodiment 2

[0031] Such as Figure 6 - Figure 7 Down:

[0032] Wherein, the roller 5 is provided with a connecting shaft 51, a sliding mechanism 52, a curved plate 53, and the connecting shaft 51 is bonded to the inner side of the curved plate 53, and the sliding mechanism 52 is mounted on the outside of the curved plate 53, said The connecting shaft 51 is embodied inside the fixing frame 4, the sliding mechanism 52 is provided with four, and the bending shaft 53 is a bending structure having a small bending coefficient, and the sliding mechanism 52 is loaded with the goods. When there is a certain flexibility while avoiding the sliding mechanism 52 depression.

[0033] Wherein, the sliding mechanism 52 is provided with a sliding block 521, a force plate 522, a friction strip 523 that is fitted to the surface of the force plate 522, and the friction strip 523 is mounted to the surface of the sliding block 521, The force plate 522 is embodied outside of the curved plate 53, the friction strip 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com