Metal structural part multi-layer single-pass continuous electric arc additive manufacturing method and system

A metal structure, multi-layer single-channel technology, applied in the field of additive manufacturing, can solve problems such as non-fusion, discontinuous additive process, uneven chemical composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

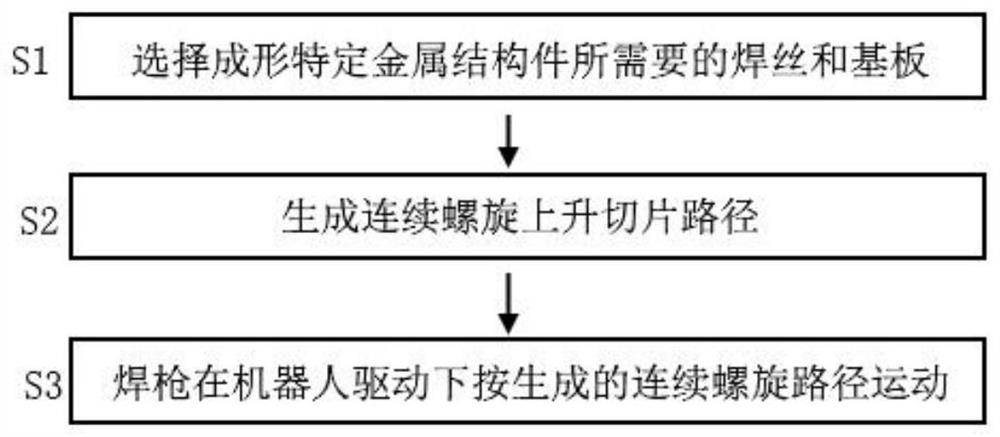

Method used

Image

Examples

Embodiment 1

[0119] Example 1: 4mm thick 4043 aluminum alloy ring-shaped regular structural part multi-layer single-channel arc additive manufacturing

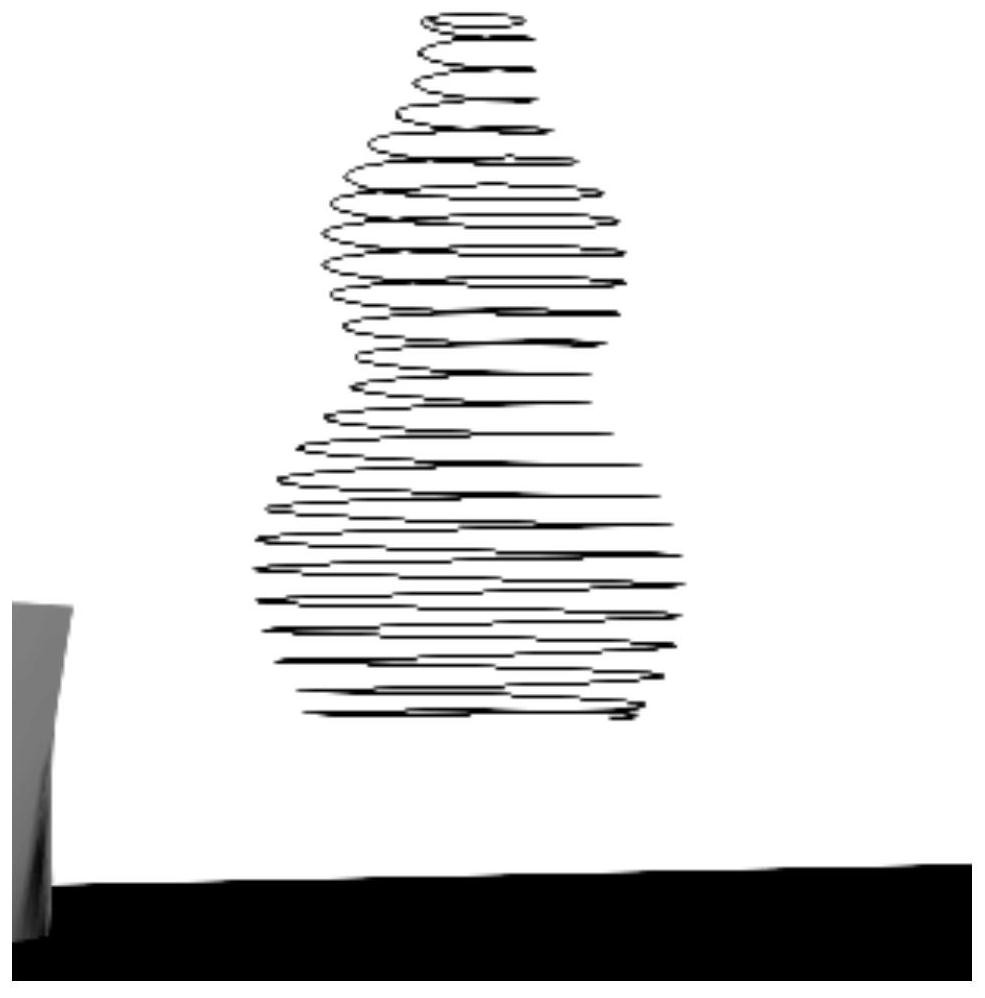

[0120] Such as figure 2 As shown, the aluminum alloy structure has a height of 200 mm and a wall thickness of 6 mm. It is formed by 181 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 1.1 mm. It is manufactured by a multi-layer single-pass electric arc additive method for metal structural parts described in the present invention. Specifically:

[0121] Print the selected 6061 aluminum alloy sheet with a substrate thickness of 15mm. The welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: select The welding process is CMT+P and CMT Advance, the welding current is 59A, the wire feeding speed is...

Embodiment 2

[0125] Example 2: 8mm thick 4043 aluminum alloy twisted polygon ring structure multi-layer single-channel arc additive manufacturing

[0126] The difference from Example 1 is:

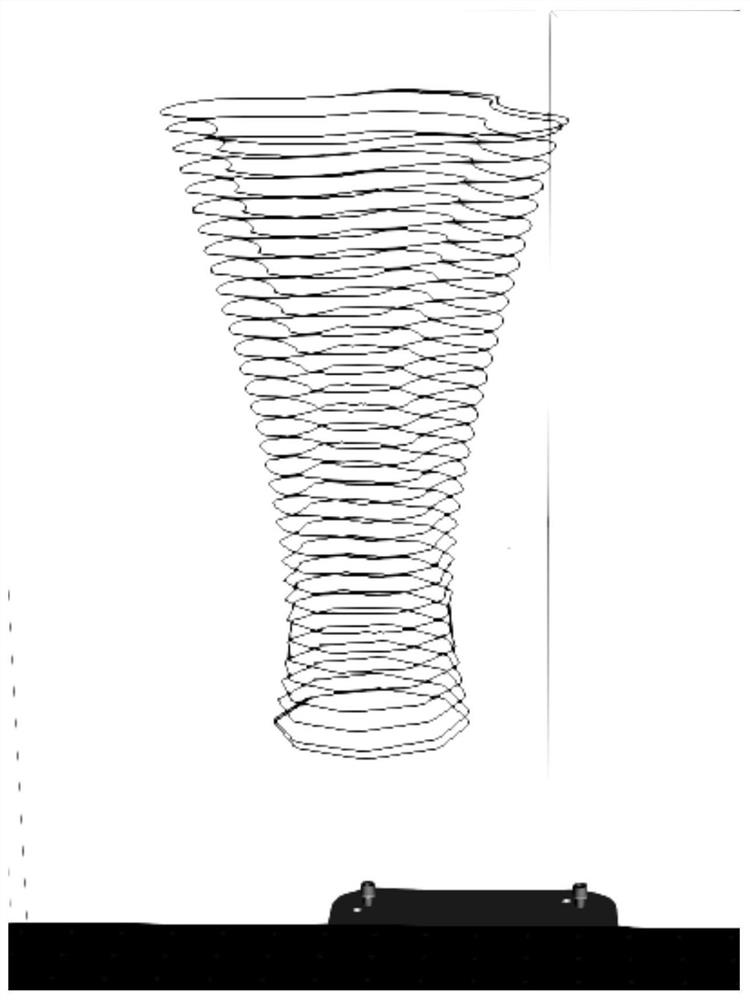

[0127] Such as image 3 As shown, the aluminum alloy structure has a height of 500 mm and a wall thickness of 8 mm. It is formed by 556 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 0.9 mm. It is manufactured by a multi-layer single-channel continuous arc additive method for metal structural parts described in the present invention. Specifically:

[0128] Print the selected 6061 aluminum alloy sheet with a substrate thickness of 16mm. The welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a suitable set of forming process parameters: select welding The process is CMT+P, the welding current is 90A...

Embodiment 3

[0132] Example 3: Multi-layer single-pass arc additive manufacturing of 6mm thick stainless steel regular structure

[0133] Such as Figure 4 As shown, the height of the stainless steel structural part is 420 mm, the wall thickness is 6 mm, and it is formed by 323 layers of continuous spiral welding arc additive manufacturing, and the height of each layer of welding seam is 1.3 mm. It is manufactured by a multi-layer single-channel continuous arc additive method for metal structural parts described in the present invention. Specifically:

[0134] Print the selected Q235 carbon steel substrate with a thickness of 16mm. The welding wire used is 308L stainless steel welding wire with a diameter of 0.8mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: Selective welding The process is CMT, the welding current is 90A, the wire feeding speed is 8.5m / min, the welding speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com