High-efficiency adjustable gear burr grinding device for machining

A mechanical processing and high-efficiency technology, applied in mechanical equipment, belts/chains/gears, gear teeth, etc., can solve the problems of high use limitations, low grinding efficiency, poor adjustment effect, etc., to ensure cleanliness, improve Grinding efficiency and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

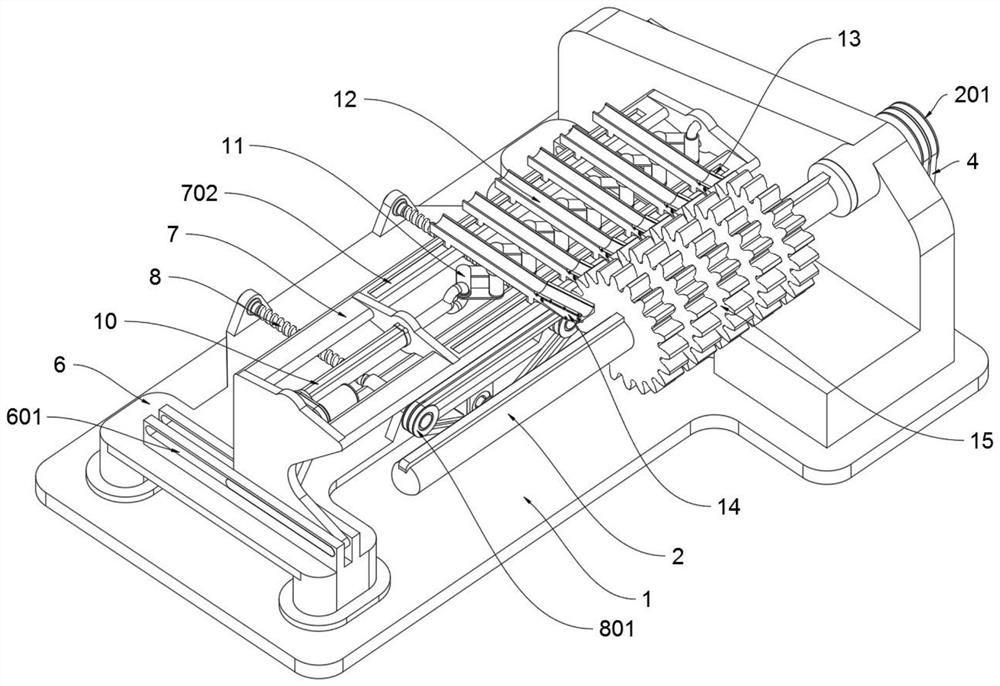

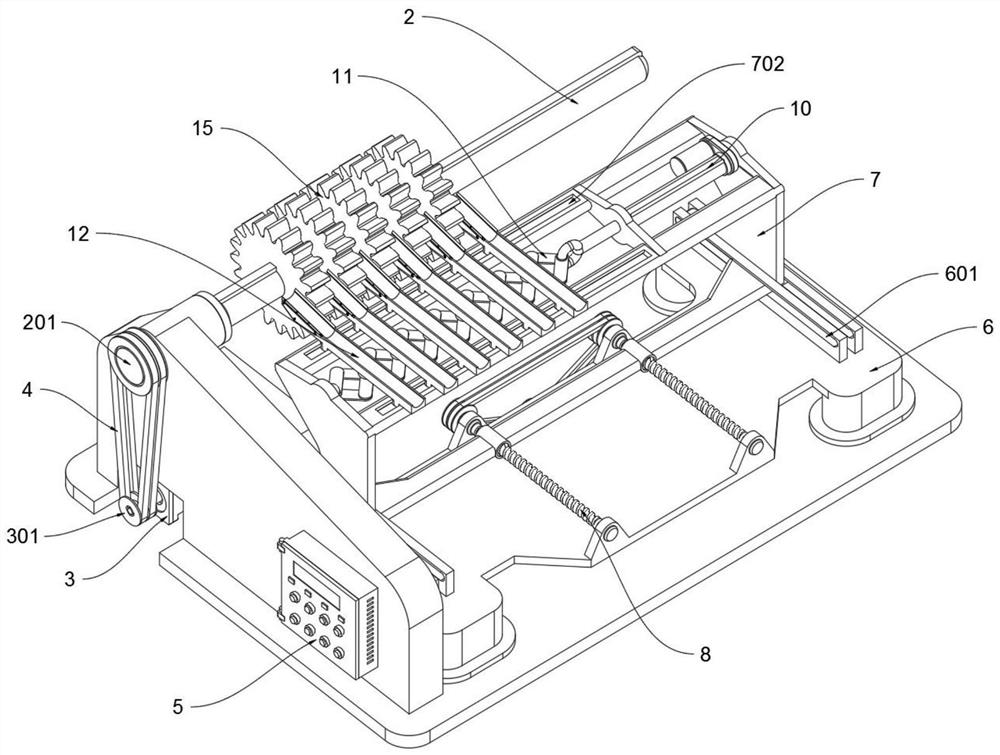

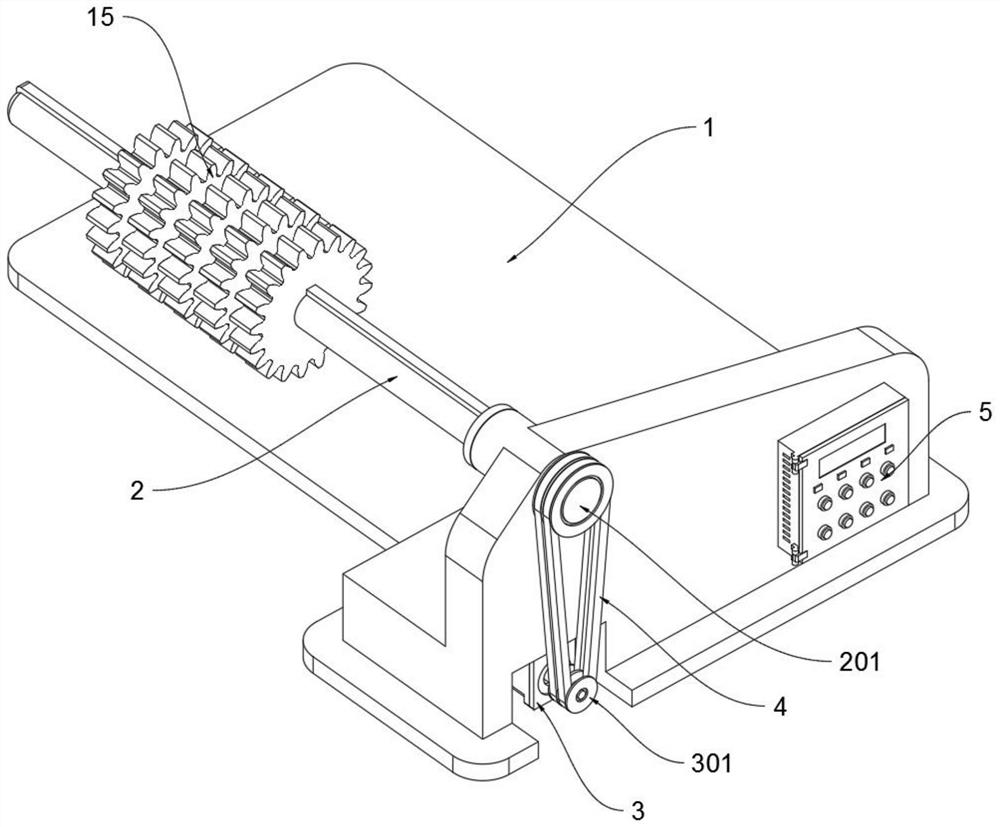

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033]The invention provides a high-efficiency adjustable gear burr grinding device for mechanical processing, which includes a drive shaft 2, a drive motor 3, a tool support seat 6, a tool support frame 7, an adjustment motor 9, an electric push rod 10, a telescopic frame 11 and The cutting blade 13; the driving shaft 2 is connected to the top of the base 1, and the gear 15 is movably connected to the outside of the driving shaft 2; the driving motor 3 is electrically connected to the control electric box 5 through the power line, and the control electric box 5 is installed on the right side of the base 1 On the side outer wall, and the control electric box 5 is connected with the external power supply line; the right end of the driving shaft 2 is connected to the top of the right end of the base 1, and the right end of the driving shaft 2 is provided with a driven pulley A201, and the driving motor 3 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com