A kind of scaffold material for bone repair and its preparation method and application

A scaffold material and bone repair technology, applied in the field of bioengineering, can solve the problem that the speed of bone repair cannot meet the needs of patients, and achieve the effect of promoting mineralization and bone repair process and promoting deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also proposes a preparation method of bone repair scaffold material, the preparation method comprising:

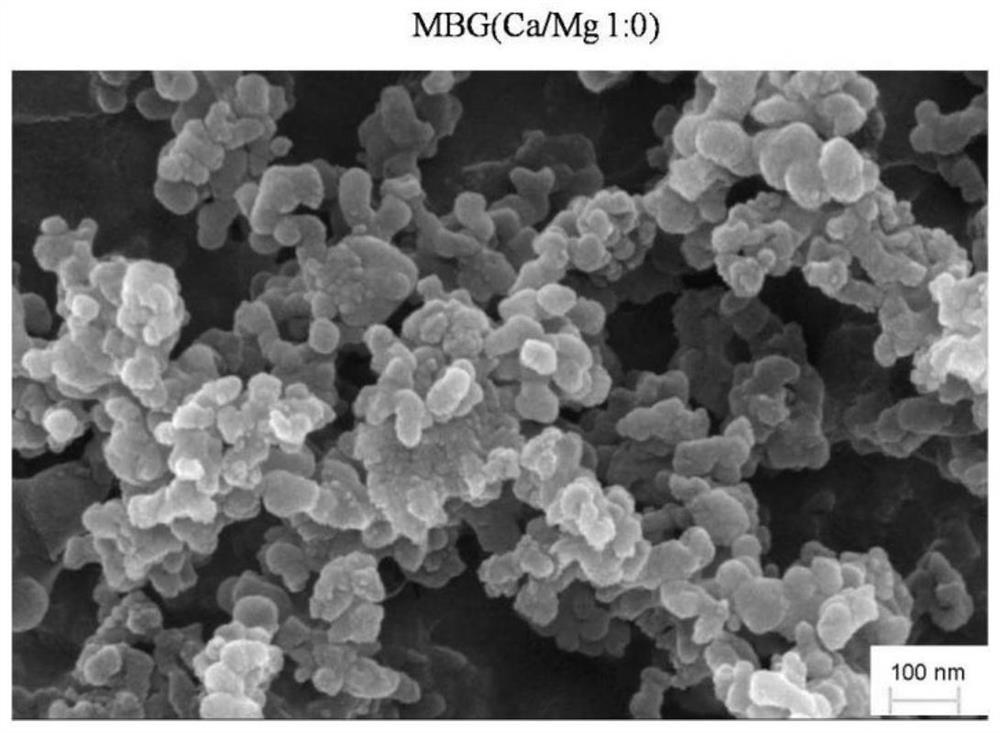

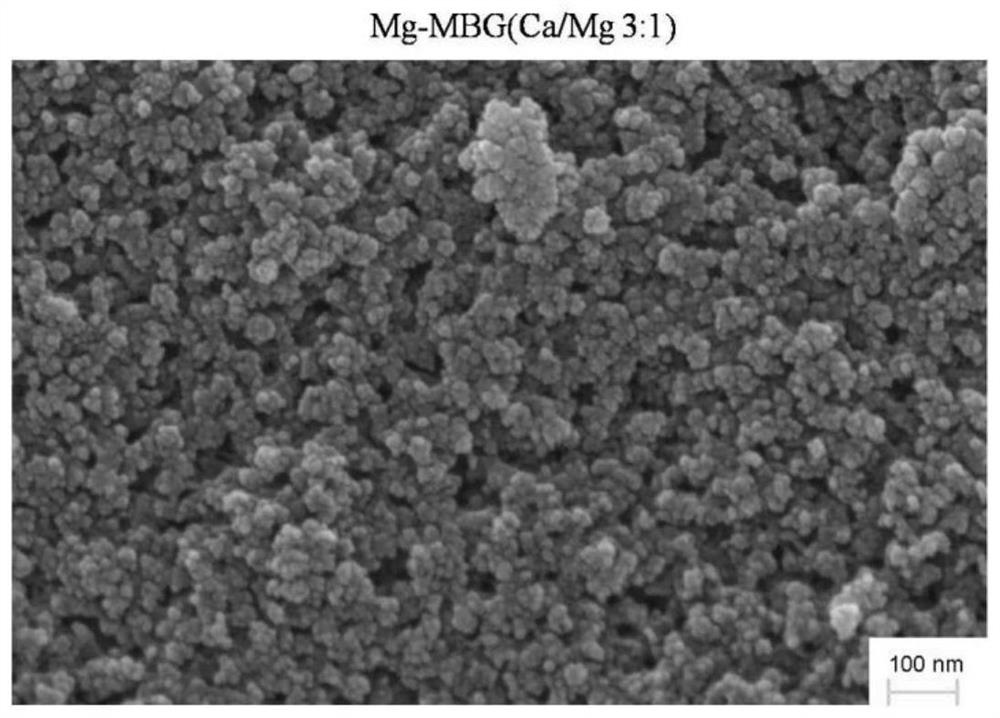

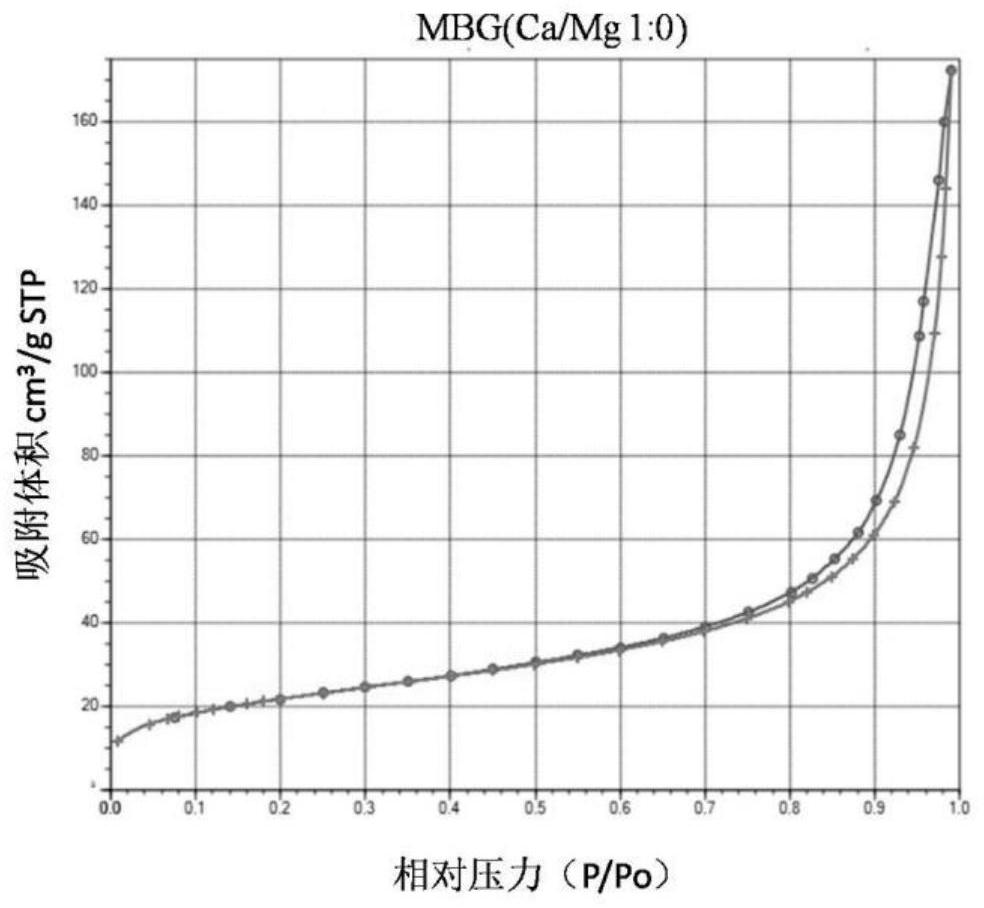

[0042] S1: Add the pore-enlarging agent to the acidic solution of the structure-directing agent, add magnesium source, calcium source, silicon source and phosphorus source, stir at 40-50°C until a uniform mixed solution is formed, and adjust the pH value of the mixed solution to Alkaline (under alkaline conditions, the pore order of the obtained mesoporous material can be improved, and a certain stability can be maintained), at 90-110°C (at this temperature, the curled carbon chain at room temperature will straighten And expand the volume, causing the diameter of the micelles to increase, thereby increasing the pore size) standing still to obtain a precipitate (further reaction crystallization, forming a gel), washing the precipitate to a pH of 7 to 7.4 (the purpose of washing is to remove adsorbed or entrained Impurities and solvents, pH is us...

Embodiment 1

[0075] The present embodiment provides a method for preparing a scaffold material for bone repair, comprising:

[0076] 5g structure directing agent PEO 20 -PPO 70 -PEO 20 (P123) was completely dissolved in 300mL of water, and the pH value of the solution was adjusted to 1 with concentrated HCl, and 7g of pore-enlarging agent 1,3,5-mesitylene (TMB) was added, stirred for 4 hours until uniform, and then magnesium nitrate, calcium nitrate, 10mL tetraethyl orthosilicate (TEOS), 2.6g triethyl phosphate (TEP), wherein the molar ratio of magnesium to calcium in magnesium nitrate and calcium nitrate is (1:3), after stirring at 40°C for 24h, use concentrated Ammonia water was used to adjust the pH to 10, and after adding the solution into the reaction kettle, it was allowed to stand at 90° C. for 80 hours to obtain a precipitate. The resulting precipitate was centrifuged at 10,000 rpm, the supernatant was removed, the precipitate was washed several times with deionized water to pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com