Nickel selenide composite material loaded with ferronickel tannate and preparation method and application of nickel selenide composite material

A composite material, nickel-iron tannin technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as low overpotential, and achieve the effects of low synthesis temperature, good oxygen production performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, cut the nickel foam base to 1×3cm 2 After that, the nickel foam substrate was sequentially soaked in acetone solution, water and 3M HCl aqueous solution and ultrasonicated for 15 min.

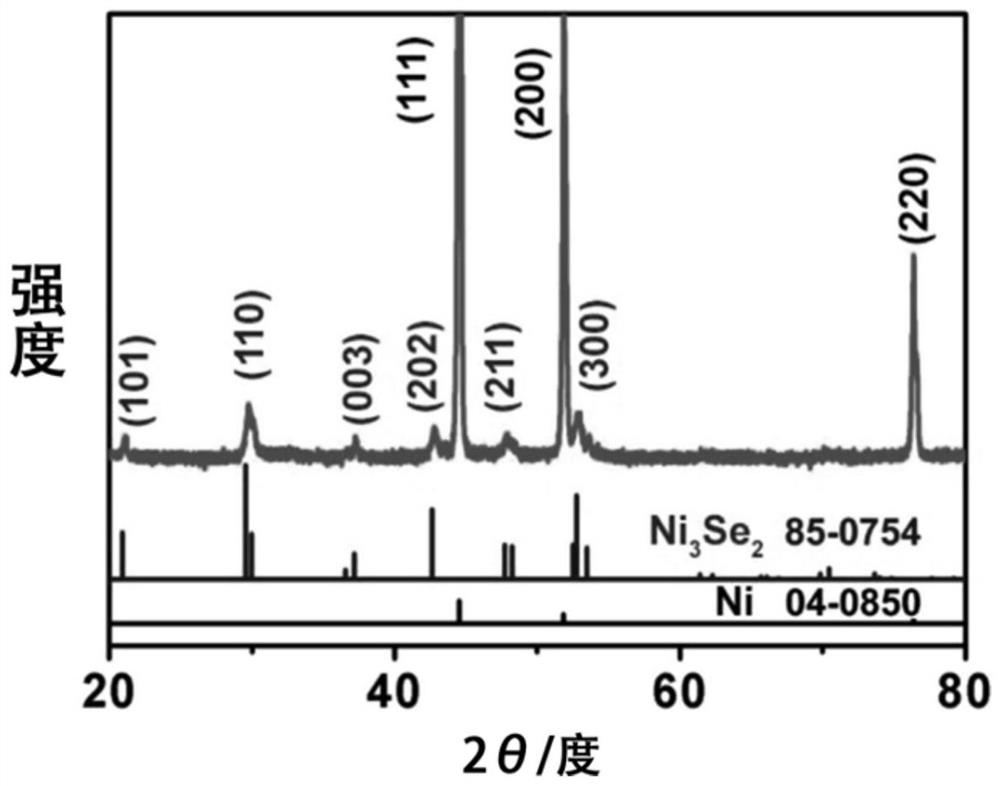

[0031] Step 2, mix 0.05g of selenium powder, 2.0ml of ethylenediamine, and 3.0ml of water in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take a piece of the cleaned nickel foam substrate treated in step 1 and put it into a hydrothermal kettle, then seal the hydrothermal kettle and react at a temperature of 180° C. for 5 hours.

[0032] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, wash the foamed nickel substrate with black precipitation on the surface with water and alcohol respectively, and let it air dry naturally.

[0033] Step 4, the nickel foam that the surface that step 3 obtains is the black nickel selenide product is placed in the middle of an empty 20mL container, then add the ferric chloride of 2.5mL 10mM and th...

Embodiment 2

[0036] Step 1, cut the nickel foam base to 1×3cm 2 After that, the nickel foam substrate was sequentially soaked in acetone solution, water and 3M HCl aqueous solution and ultrasonicated for 15 min.

[0037] Step 2, mix 0.05g of selenium powder, 2.0ml of ethylenediamine, and 3.0ml of water in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take a piece of the treated clean nickel foam substrate in step 1 and put it into a hydrothermal kettle, then seal the hydrothermal kettle and react at a temperature of 170° C. for 5 hours.

[0038] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, wash the foamed nickel substrate with black precipitation on the surface with water and alcohol respectively, and let it air dry naturally.

[0039]Step 4, the nickel foam that the surface that step 3 obtains is the black nickel selenide product is placed in the middle of an empty 20mL container, then add the ferric chloride of 2.5mL 10mM and the n...

Embodiment 3

[0042] Step 1, cut the nickel foam base to 1×3cm 2 After that, the nickel foam substrate was sequentially soaked in acetone solution, water and 3M HCl aqueous solution and ultrasonicated for 15 min.

[0043] Step 2, mix 0.05g of selenium powder, 2.0ml of ethylenediamine, and 3.0ml of water in a stainless steel hydrothermal kettle, and stir for 15 minutes. Then take a piece of the cleaned nickel foam substrate treated in step 1 and put it into a hydrothermal kettle, then seal the hydrothermal kettle, and react at a temperature of 160° C. for 5 hours.

[0044] Step 3, after the temperature of the hydrothermal kettle in step 2 is cooled, wash the foamed nickel substrate with black precipitation on the surface with water and alcohol respectively, and let it air dry naturally.

[0045] Step 4, the nickel foam that the surface that step 3 obtains is the black nickel selenide product is placed in the middle of an empty 20mL container, then add the ferric chloride of 2.5mL 10mM and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com