Steam turbine valve flow fitting method and system

A valve flow, steam turbine technology, applied in the field of power system, can solve the problems of low test frequency, deviation of valve flow characteristic curve, limited data volume, etc., to achieve the effect of improving fitting speed and fast and accurate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

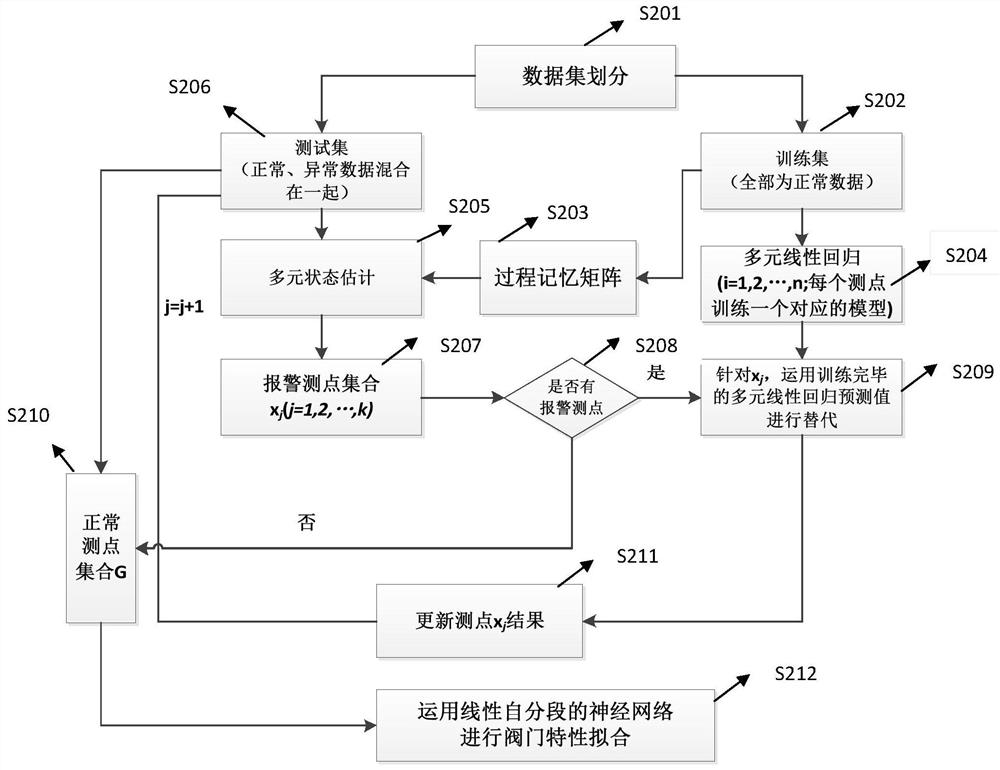

[0068] The invention provides a steam turbine valve flow fitting method. Such as figure 2 A flow chart of a steam turbine valve flow fitting method is given.

[0069] In step S201, first determine the observation point vectors related to the turbine valve flow characteristics: main steam flow, main steam pressure, main steam temperature, post-valve pressure, valve flow and valve opening command. These indicators constitute the observation point vector.

[0070] In step S202, the observation point data including the normal operation of the valve under various working conditions within a period of time is extracted as a training set.

[0071] In step S206, normal and abnormal data are mixed together as a test set.

[0072] In step S203, the process memory matrix D is first constructed for the training set 6×N . Where: 6 represents the number of observation points in step S201, and N represents the length of the time period.

[0073] In step S204, for the normal operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com