On-site formwork-erecting-free longitudinal and transverse wall connecting structure for superposed shear wall and construction process

A superimposed shear wall, formwork-free technology, applied in building structures, walls, structural elements, etc., can solve the problems of limited application height, short length, and inability to apply to high-rise residential buildings, etc., to improve on-site construction efficiency, The effect of strong connection integrity and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

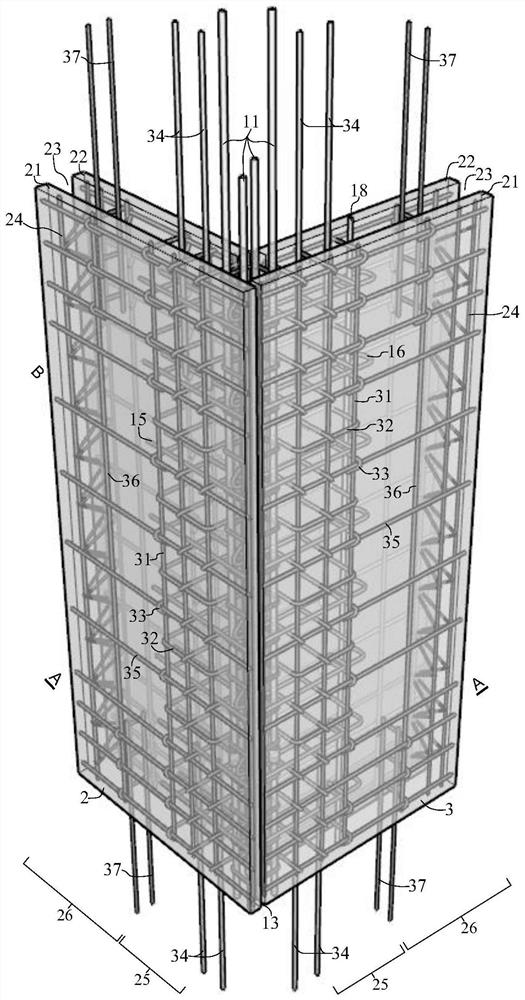

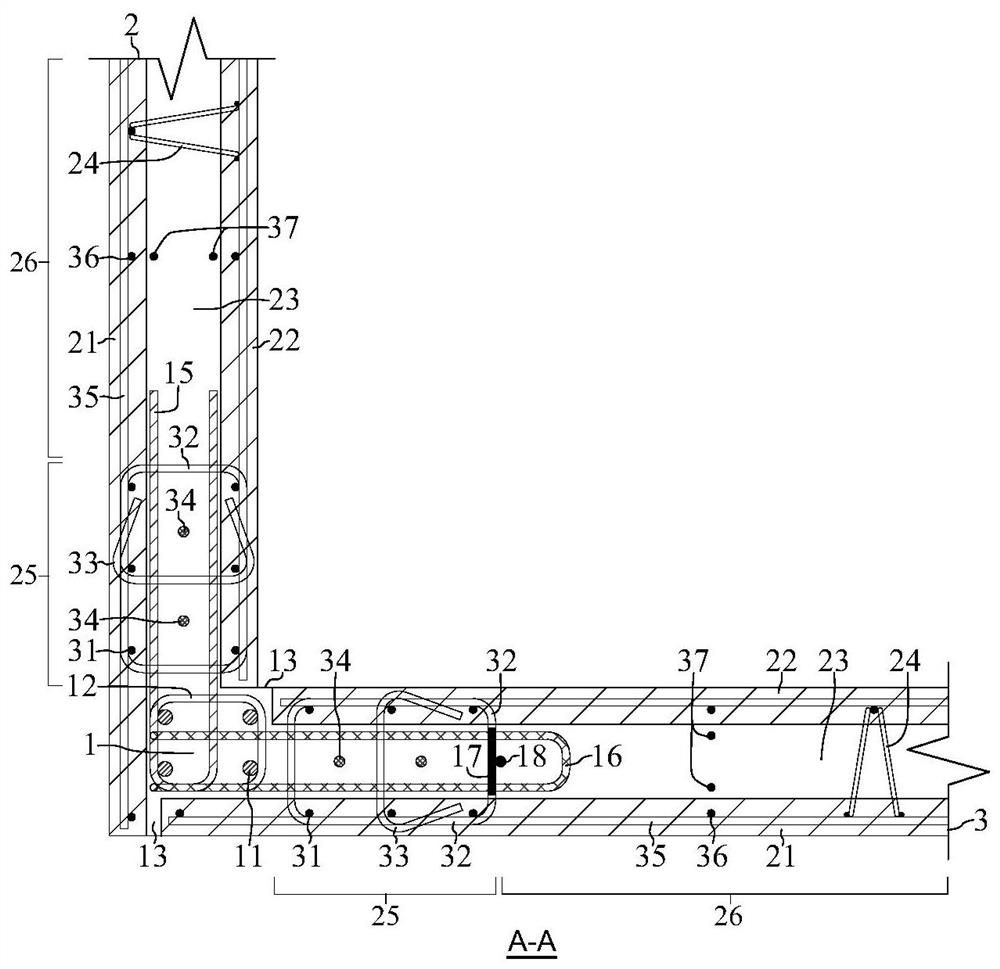

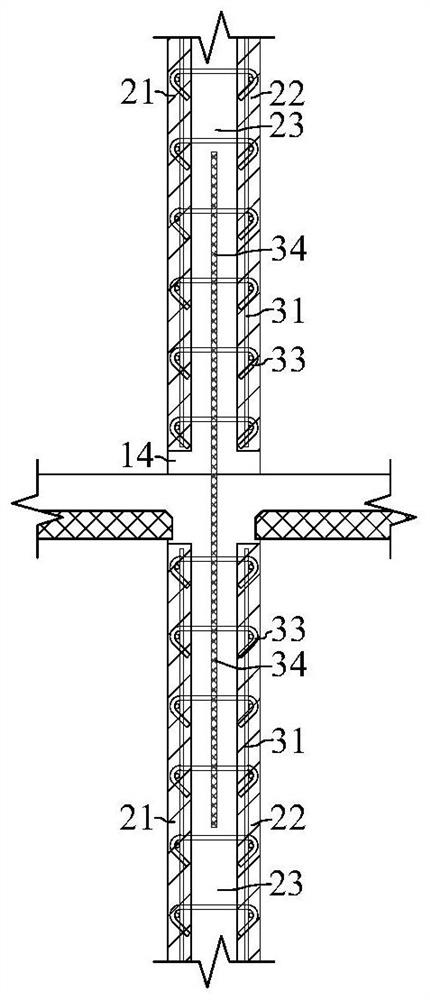

[0048] The invention provides an on-site formwork-free vertical and horizontal wall connection structure for superimposed shear walls and its corresponding construction technology. Such as Figure 1 to Figure 25 As shown, it mainly includes the vertical and horizontal prefabricated walls and the vertical post-casting section 1 at the joint of the vertical and horizontal prefabricated walls. The cavity 23 is composed. The present invention comprehensively considers the on-site construction of the vertical post-casting section and the integrity of the node connection, and optimizes and improves the node structure, specifically:

[0049] At the L-shaped or T-shaped node position where the vertical and horizontal prefabricated walls are connected, the precast concrete panels of the vertical and horizontal prefabricated walls all extend to the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com