Wind power tower drum foundation ring ribbed beam type foundation based on combined structure

A combined structure and wind power tower technology, applied in basic structure engineering, construction and other directions, can solve the problems of difficult pouring of concrete, large amount of concrete, large foundation volume, etc., to avoid variable-section formwork, high construction efficiency, and reduced Effect of Material Amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

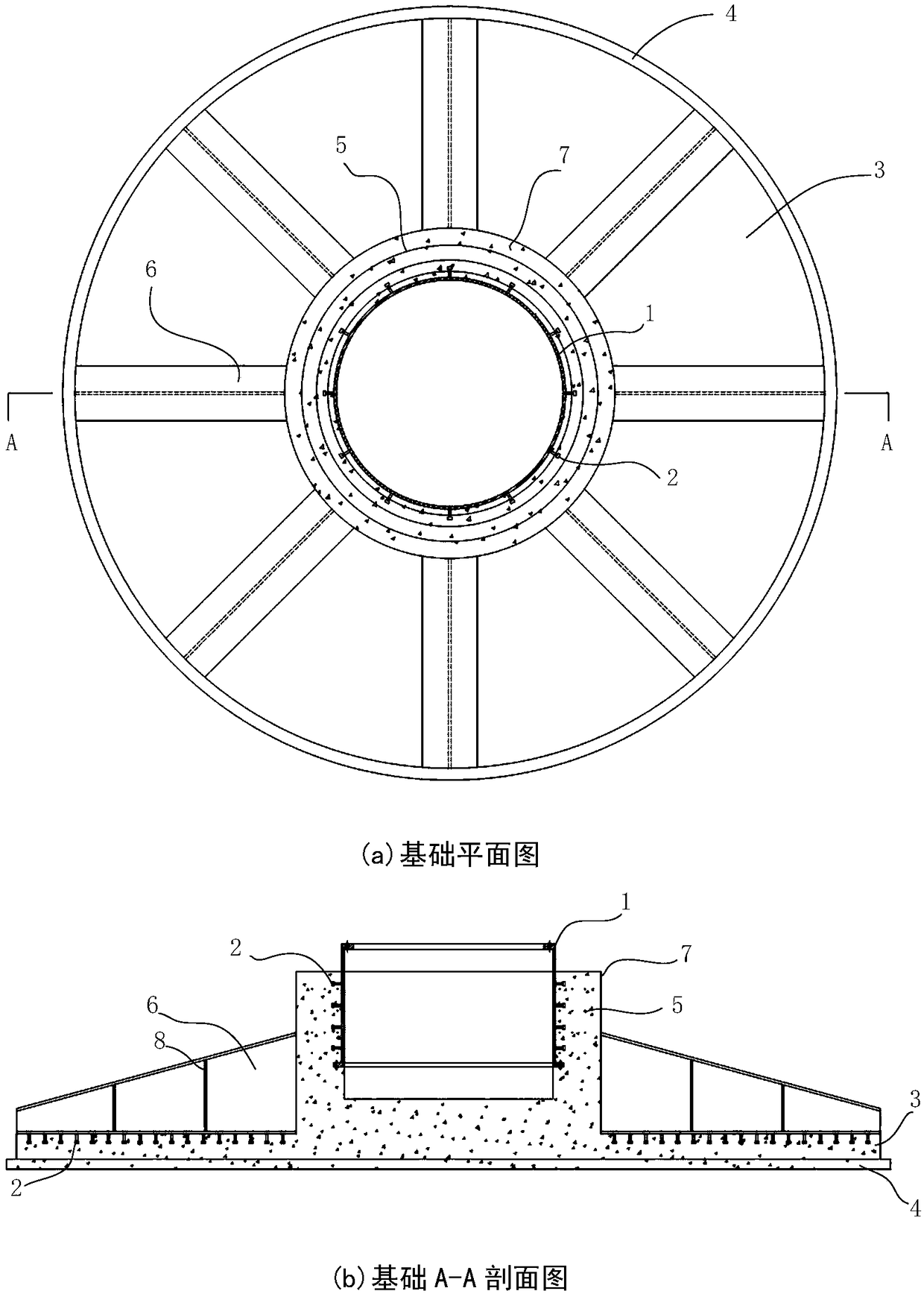

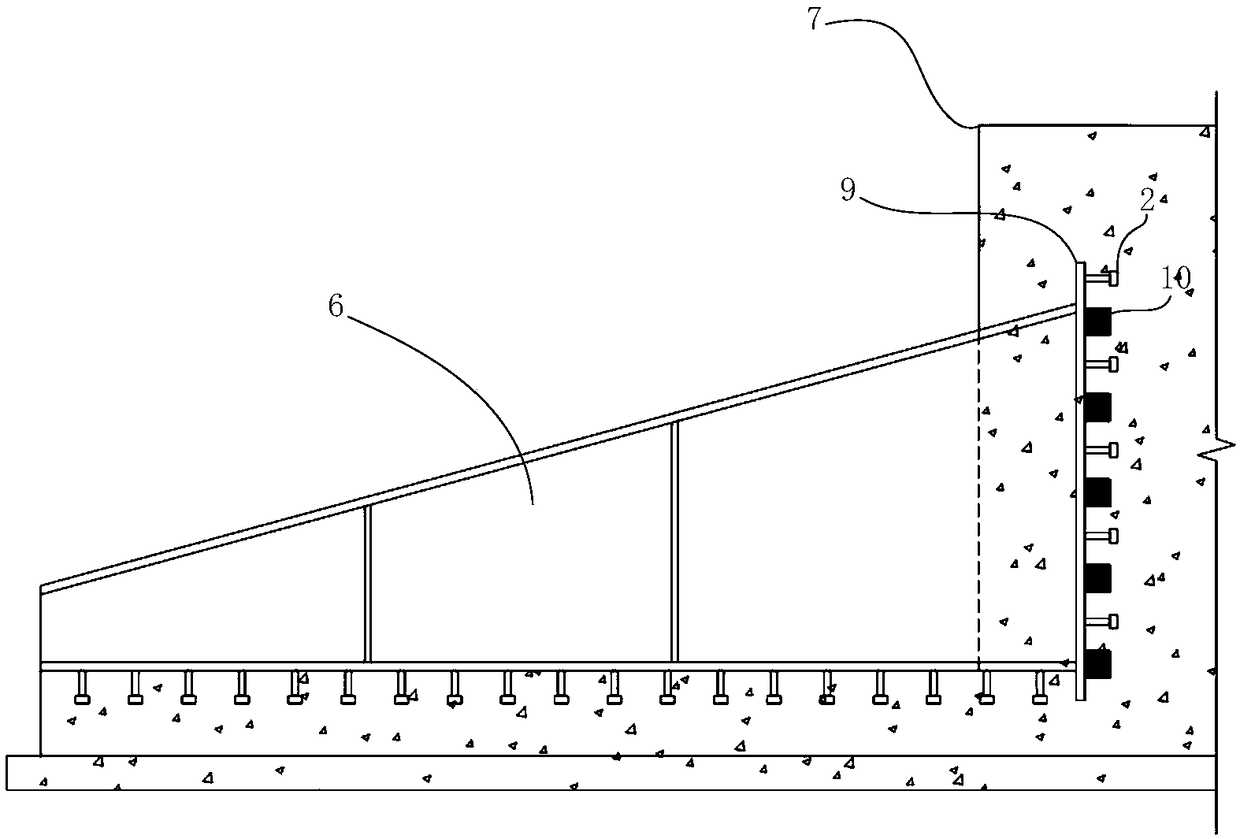

[0021] Such as figure 1 As shown, a wind power tower foundation ring rib beam foundation based on composite structure, the system includes foundation ring (1), studs (2), circular concrete floor (3), H-shaped steel rib beam with variable cross-section ( 6), concrete pillars (7), etc. The lower part of the foundation ring (1) is poured together with the concrete bottom plate (3), and the connection is strengthened by the studs (2) arranged along the ring direction. A cushion layer (4) is arranged under the concrete base plate. The variable-section H-shaped steel rib beam (6) is connected to the concrete bottom plate (3) through studs (2) arranged along the lower flange. The web of the rib beam is provided with longitudinal stiffeners (8), and the end of the beam extends into the concrete pillar (7). The concrete pillar (7) adopts a hollow structure, and removes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com