Roller washing machine

A technology for drum washing machines and inner drums, which can be applied to other washing machines, washing machines with containers, washing devices, etc., and can solve the problems of air pressure imbalance in the sealed cabin, power consumption, and affecting the sealing effect of the door seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

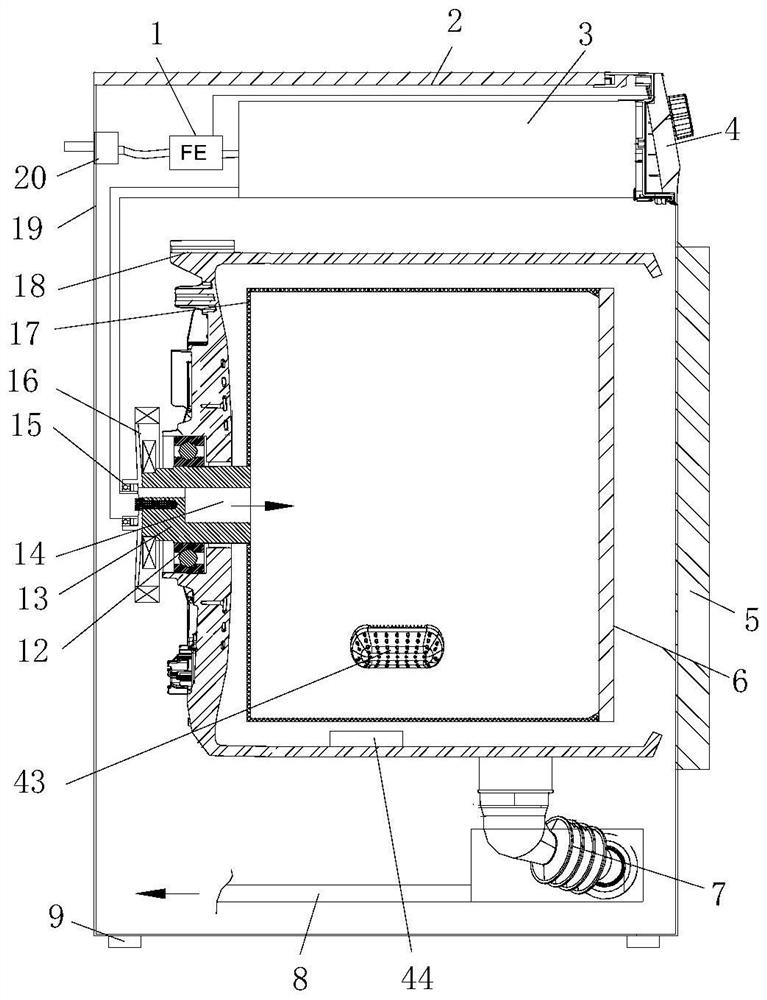

[0129] This embodiment mainly solves the problem of how to ensure the unbalanced air pressure in the sealed cabin of the inner cylinder of the drum washing machine. Specifically, the water inlet valve is suddenly closed and the water is cut off, or the water pipe network is cut off, forming a negative pressure to pump the washing water in the sealed cabin of the inner cylinder. to the pipe network; or there is gas inside the inner cylinder, making it difficult to enter the water.

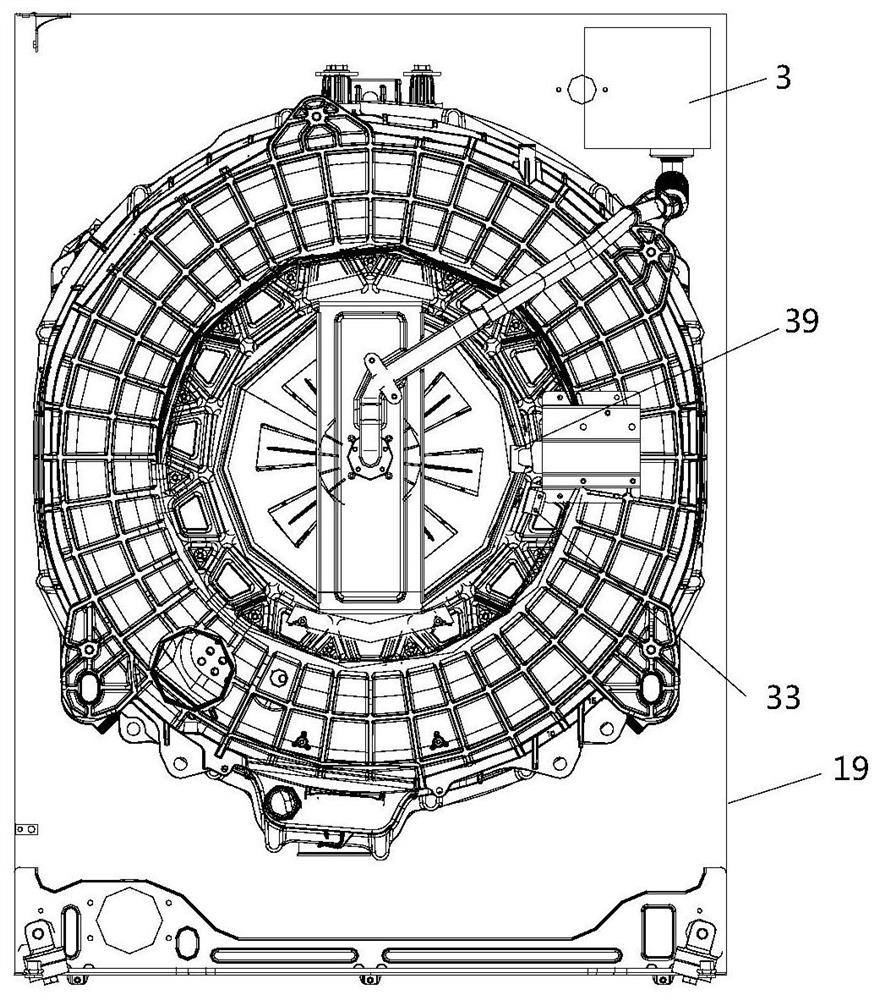

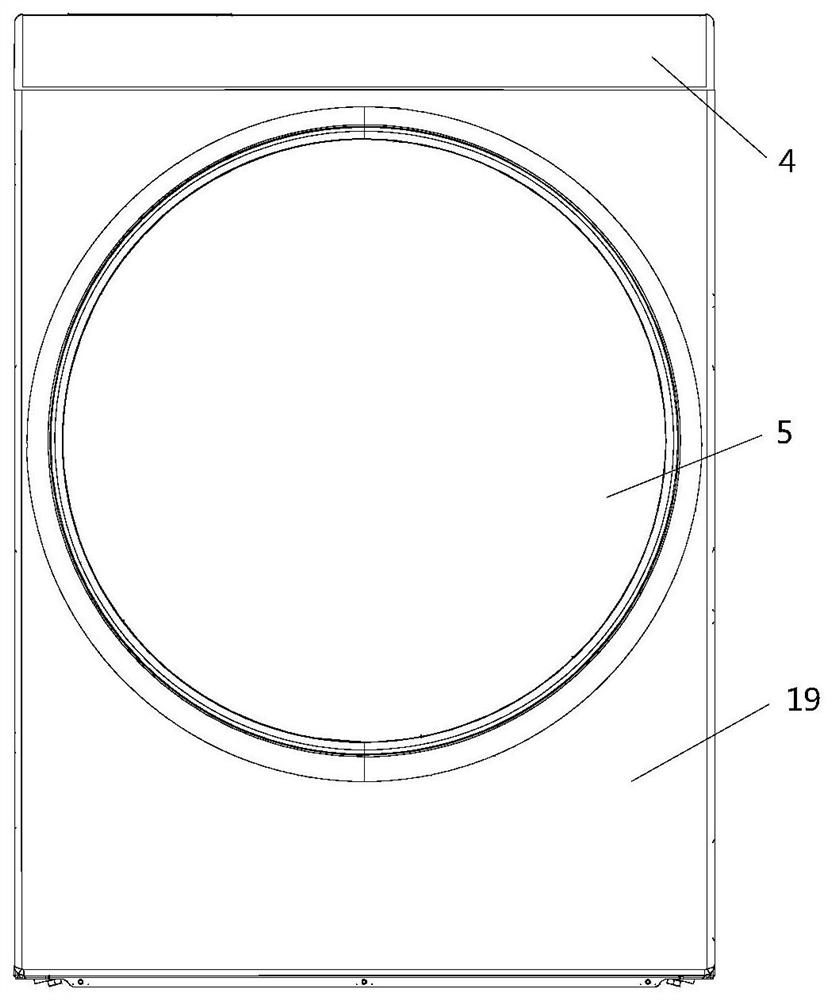

[0130] Such as Figure 9 to Figure 11 As shown, the drum washing machine described in this embodiment includes an inner cylinder 17, which is a non-porous inner cylinder, which is a water container when washing clothes, and also includes an inner cylinder for connecting the inner cylinder 17 with the external environment to balance the interior of the inner cylinder. Air pressure air pressure balance mechanism.

[0131] When water enters, the gas in the airtight compartment of the inner cylinder ca...

Embodiment 2

[0144] Different from the first embodiment above, the air pressure balance mechanism described in this embodiment includes a booster mechanism and / or a pressure relief mechanism for communicating the inner cylinder with the external environment to balance the air pressure inside the inner cylinder 17 .

[0145]The pressurization mechanism described in this embodiment includes a pressurization channel 28 and a negative pressure safety valve 29. The negative pressure safety valve 29 is arranged on the pressurization channel 28, and is used for single-use when the internal pressure of the inner cylinder 17 is lower than the atmospheric pressure of the external environment. The guide guides the pressurized hole 28, and the external environment gas enters the interior of the inner cylinder 17 through the pressurized hole 28 to be pressurized until the internal air pressure of the inner cylinder 17 is balanced with the external environment air pressure, and the negative pressure safet...

Embodiment 3

[0161] This embodiment mainly solves the problem of how to ensure that the inner cylinder serves as a water container to enter the inner cylinder of the drum washing machine.

[0162] Such as Figure 17 As shown, the drum washing machine described in this embodiment includes an outer cylinder 18, an inner cylinder 17, an inner cylinder shaft 13 and a water inlet device. The inner cylinder 17 is a water container when washing clothes, and the inner cylinder 17 passes through the inner cylinder. The cylinder shaft 13 is rotatably supported in the outer cylinder 18, and the inner cylinder shaft 13 has a hollow passage 14 inside, and the water inlet device communicates with the sealed compartment inside the inner cylinder 17 through the hollow passage 14 of the inner cylinder shaft 13.

[0163] The water inlet device described in this embodiment includes a water inlet pipeline, one end of the water inlet pipeline communicates with the water inlet valve and / or the detergent dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com