A high-grade matte continuous blowing process

A high-grade, matte technology, applied in the direction of improving process efficiency, etc., can solve the problems of increased production costs, capital backlog, oxygen lance and oxygen lance brick burnout, etc., and achieve the effect of small loss and small temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

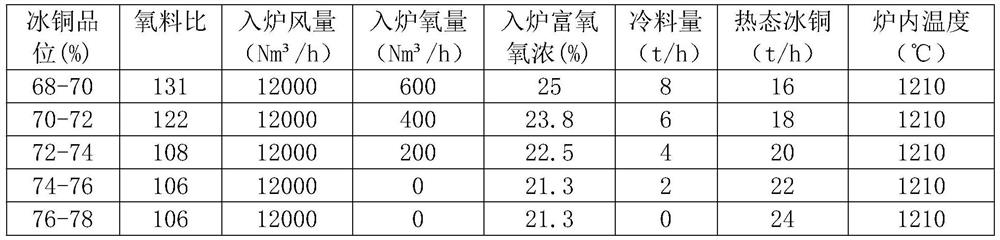

[0028] A high-grade matte continuous blowing process in the present embodiment comprises the following steps:

[0029] Step S1: the smelting bottom blowing furnace regularly sends the hot matte to the blowing furnace according to the quantity of 24 tons / hour through the connecting chute, wherein the grade of the hot matte is 76%-78%;

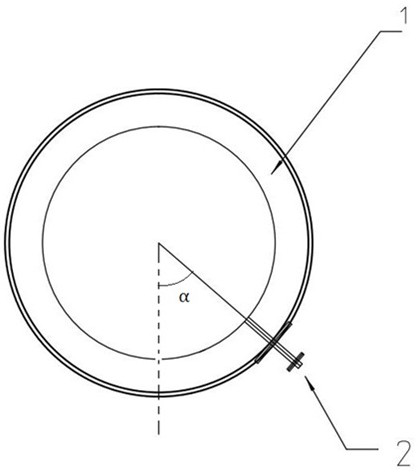

[0030] Step S2: Open the compressed air valve and the oxygen valve, set the oxygen lance entry angle to 30°, the oxygen lance mouth is 190mm away from the furnace bottom, the oxygen lance is always at the junction of the matte copper layer and the blister copper layer, and the oxygen lance is sent to the furnace through the oxygen lance. The copper layer is directly supplied with air and oxygen, so that the total air volume entering the furnace is kept at 12000Nm / h, the oxygen volume entering the furnace is kept at 500-1200Nm / h, and the oxygen-enriched oxygen concentration in the furnace is 21.3%, and then the furnace body is transferred to Blow...

Embodiment 2

[0035] A high-grade matte continuous blowing process in the present embodiment comprises the following steps:

[0036] Step S1: the smelting bottom blowing furnace regularly sends the hot matte to the blowing furnace according to the quantity of 24 tons / hour through the connecting chute, wherein the grade of the hot matte is 76%-78%;

[0037] Step S2: Open the compressed air valve and the oxygen valve, the oxygen lance entering the furnace is set at 49°, the vertical height of the lower edge of the oxygen lance is 500mm from the bottom of the furnace, the injection point of the oxygen lance is in the matte layer, and the oxygen lance injects the matte into the furnace through the oxygen lance. Direct air supply and oxygen supply, so that the total air volume entering the furnace is maintained at 12000Nm / h, the oxygen volume entering the furnace is maintained at 500-1200Nm / h, and the oxygen-enriched oxygen concentration in the furnace is 21.3%, and then the furnace body is trans...

Embodiment 3

[0042] A high-grade matte continuous blowing process in the present embodiment comprises the following steps:

[0043] Step S1: the smelting bottom blowing furnace regularly sends the hot matte to the blowing furnace according to the quantity of 24 tons / hour through the connecting chute, wherein the grade of the hot matte is 76%-78%;

[0044] Step S2: Open the compressed air valve and the oxygen valve, the oxygen lance entering the furnace is set at 60°, the vertical height of the lower edge of the oxygen lance from the furnace bottom is 705mm, the oxygen lance is in the matte layer, and the oxygen lance is directly connected to the matte layer in the furnace through the oxygen lance. Air supply and oxygen supply, so that the total air volume entering the furnace is kept at 12000Nm / h, the oxygen volume entering the furnace is kept at 500-1200Nm / h, and the oxygen-enriched oxygen concentration in the furnace is 21.3%, and then the furnace body is transferred to the blowing position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com