Microspherical cavity laser based on ultra-low threshold multi-component holmium ion-doped glass material

A glass material and multi-component technology, applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of high pumping threshold and low quality of microspheres, and achieve low collection energy efficiency, high Q value, The effect of low threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation process of the microcavity laser includes the preparation of glass and the preparation of microspheres, including the following steps:

[0044] Weigh the high-purity raw materials according to a certain ratio, and stir them in a ball mill to fully mix the various raw materials;

[0045] Then put the mixture into a corundum crucible and heat it in a high temperature furnace at 850 °C for 90 min;

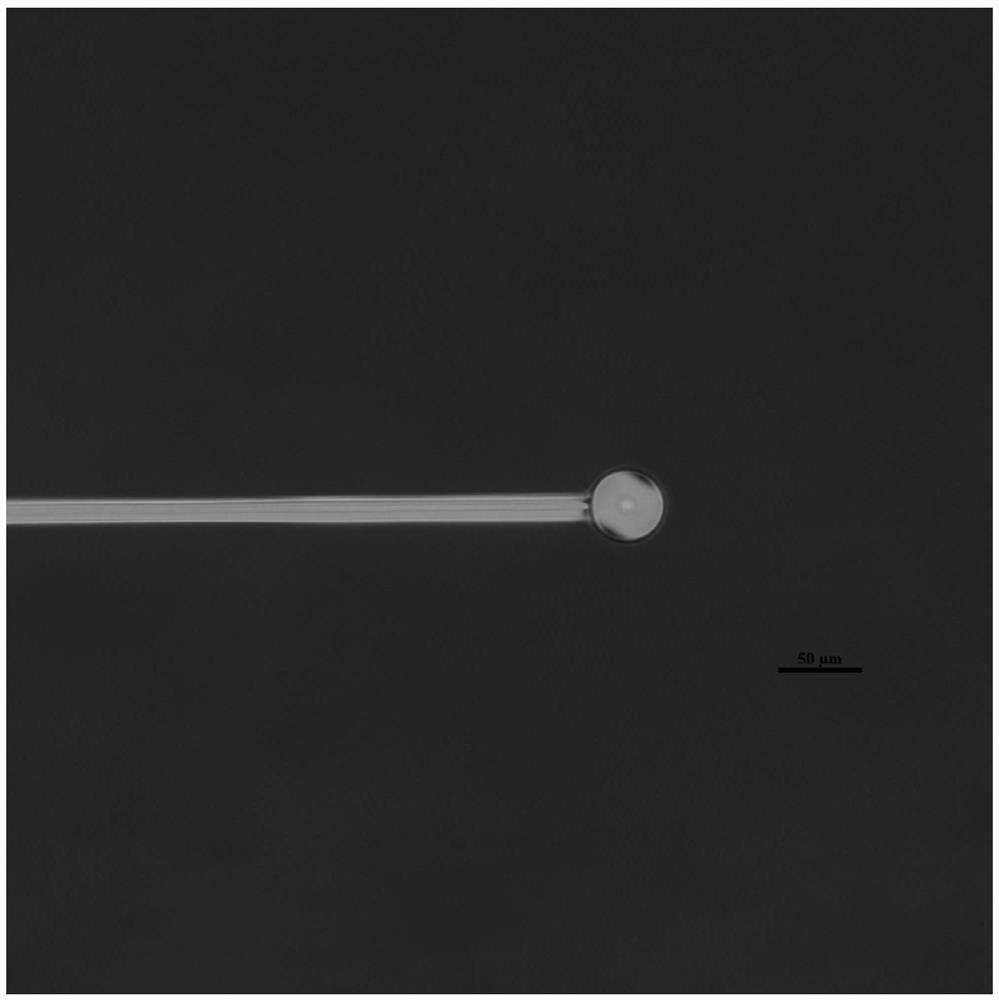

[0046]The molten glass liquid is drawn and cooled to form an optical fiber core. Use a carbon dioxide laser to taper the multi-component doped glass fiber, hang a weight on the end of the multi-component glass fiber, and use a focusing lens to focus the laser output from the carbon dioxide laser on the multi-component doped glass fiber. When the glass fiber reaches its own softening point, the glass fiber slowly falls due to the action of the heavy object, and the diameter of the fiber gradually decreases until the tapered diameter of the end of the doped glass...

Embodiment

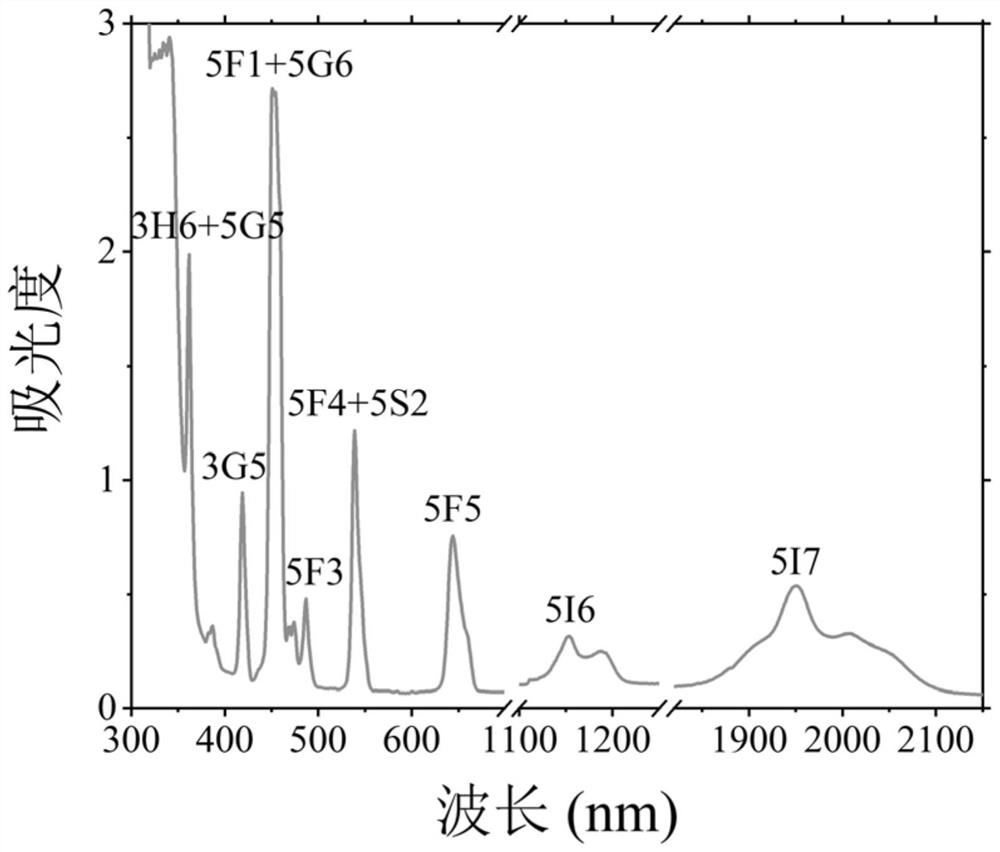

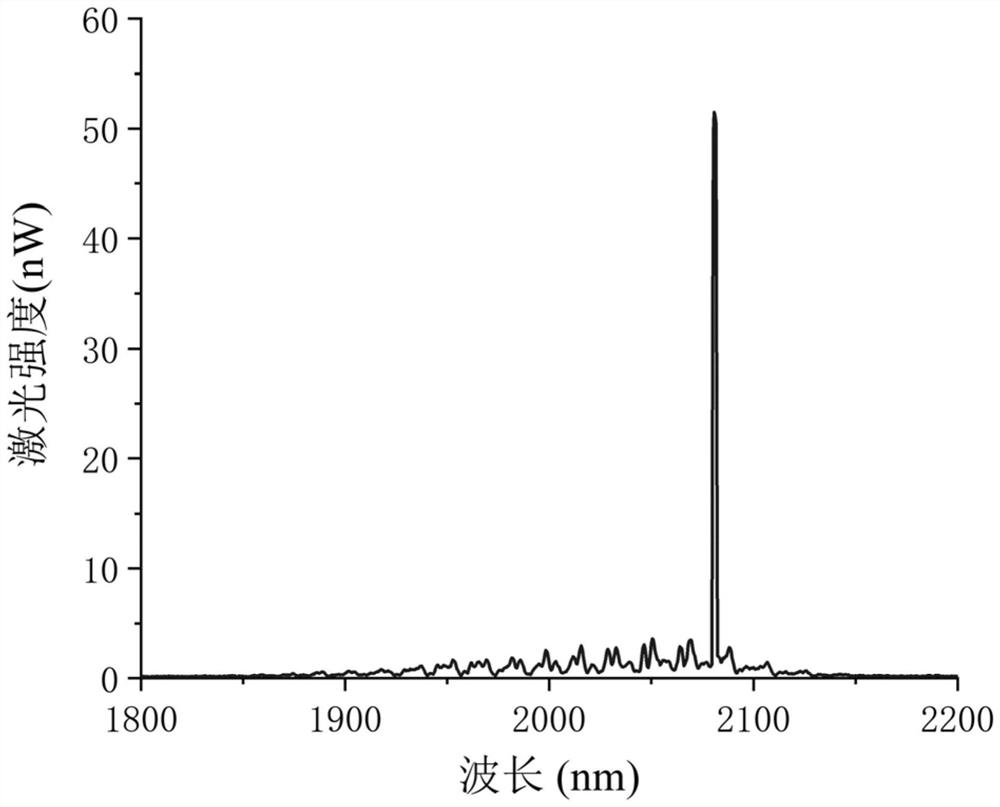

[0054] The glass used in this example is 72TeO in molar percentage 2 -20ZnO-5Na 2 CO 3 -2Y 2 O 3 -1HoF 3 , in order to prepare a molten tellurite glass with a total weight of 10g, wherein the mass of each component is 8.023g, 1.1368g, 0.37g, 0.3153g, and 0.1549g in sequence. Glass filaments are obtained from molten tellurite glass using glass rods and further prepared into tellurate microspheres. Connect the 1150nm laser and the quartz tapered fiber, and connect the spectrometer of Yokogawa AQ6375B, turn on the 1150nm laser, increase the power, and obtain the 2.08-micron laser output from the spectrometer, and its output power is 53nW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com