Multi-layer ceramic tile horizontal perpendicular-turning conveying device

A conveying device and technology in the horizontal direction is applied in the field of vertical turning conveying devices in the horizontal direction of multi-layer ceramic tiles. The effect of reducing the physical strength of the operator and having a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and this embodiment.

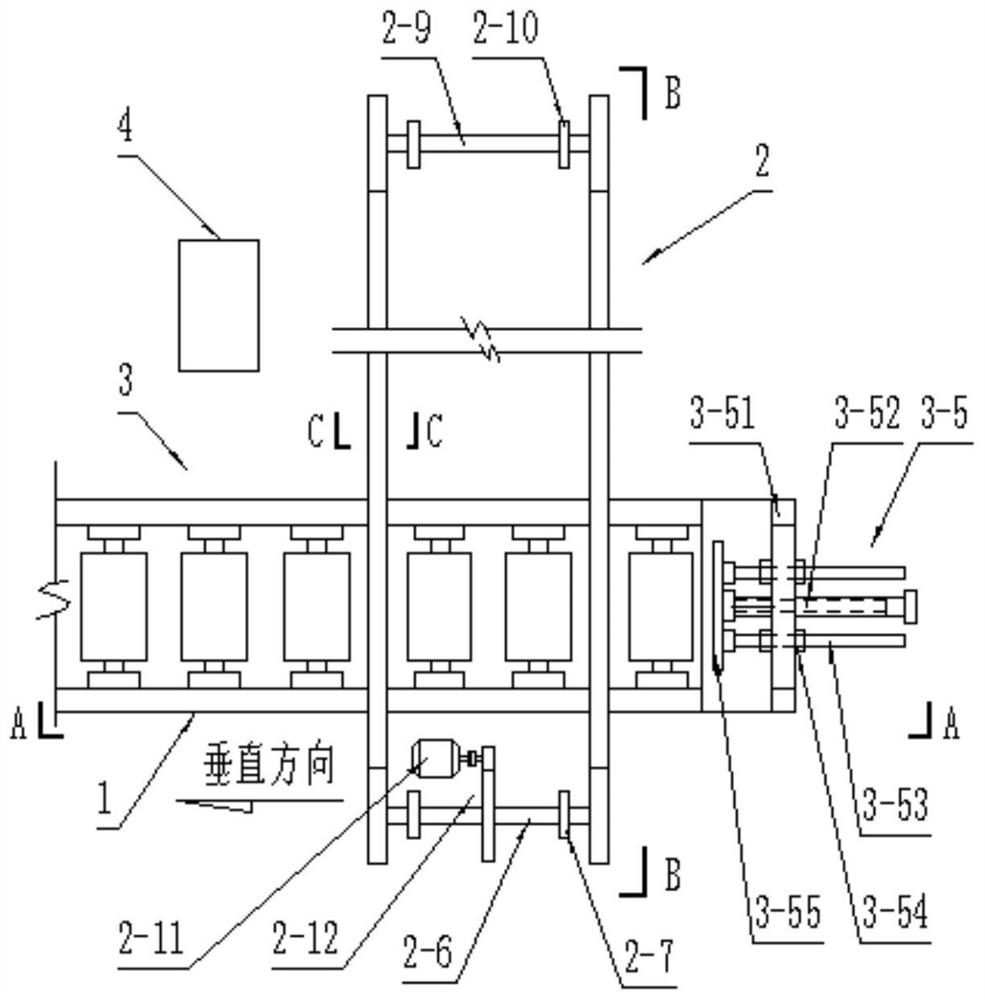

[0037] Such as Figure 1-5 Shown, a kind of multilayer ceramic tile horizontal direction vertical turning conveying device, comprises frame (1), linear direction conveying device (2), vertical turning conveying device (3), intelligent automatic control cabinet (4); Said machine The frame (1) is fixed horizontally on the ground, the linear direction conveying device (2) and the vertical turning conveying device (3) are horizontally fixedly arranged on the frame (1), and the intelligent automatic control cabinet ( 4) It is arranged on one side of the conveying device (2) in the linear direction;

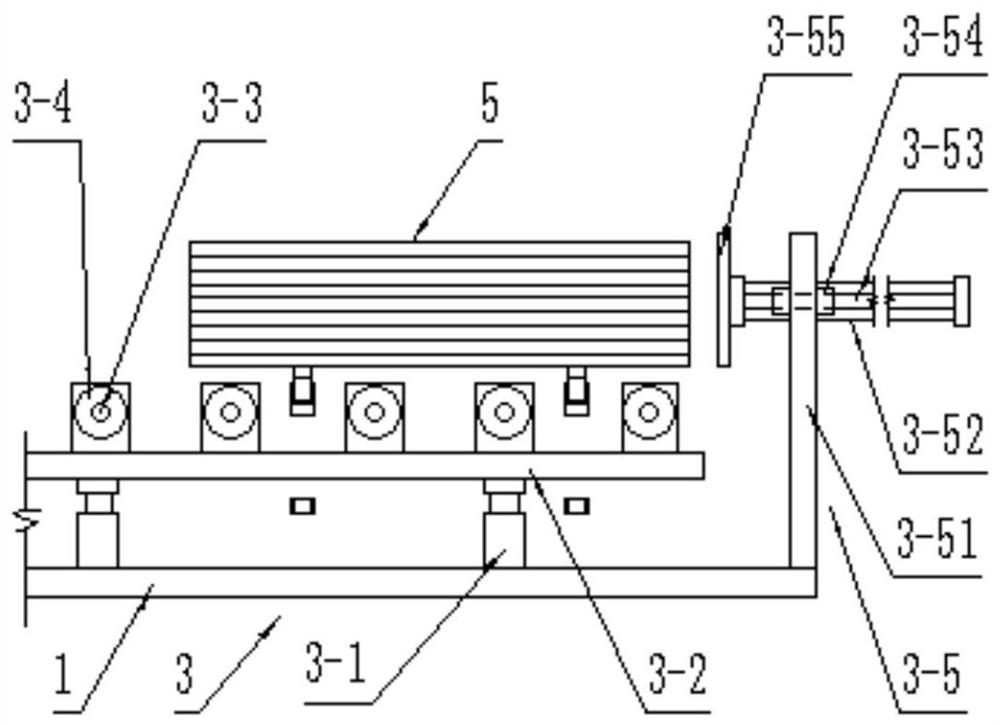

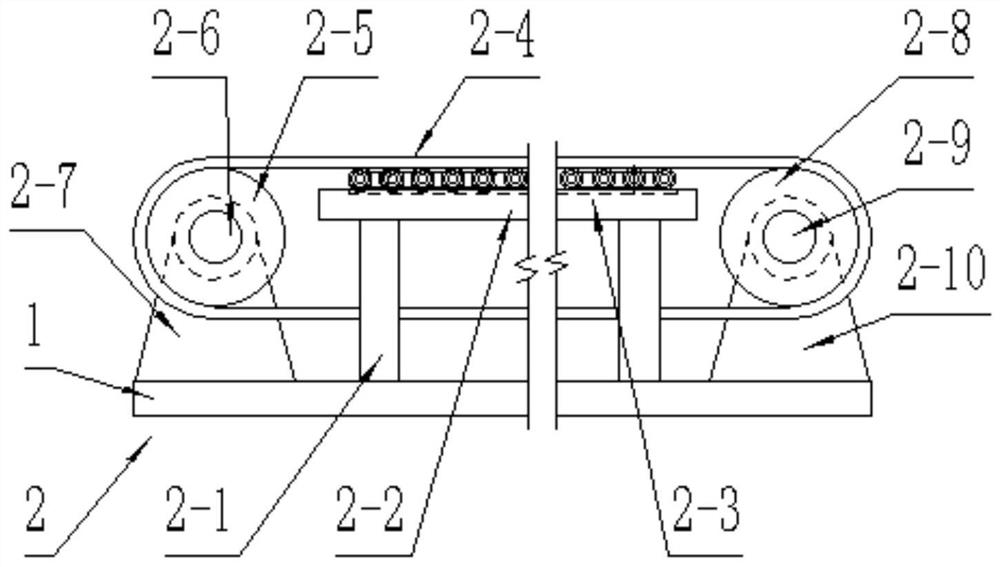

[0038] The linear direction conveying device (2) comprises a supporting column (2-1), a load-bearing beam (2-2), a sprocket device (2-3), a conveying belt (2-4), and a main pulley (2-5) , the main connecting shaft (2-6), the main tile frame (2-7), the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com