Production method for vertical stranded tension insulating pipe

A production method and technology of insulating pipes, applied in the direction of tubular objects, applications, coatings, etc., can solve the problems of acid, alkali and salt corrosion resistance, excessive deflection, and insufficient aging resistance, so as to improve tensile strength and adaptability , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

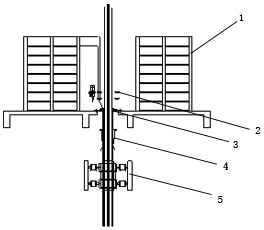

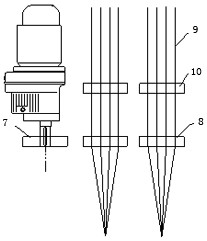

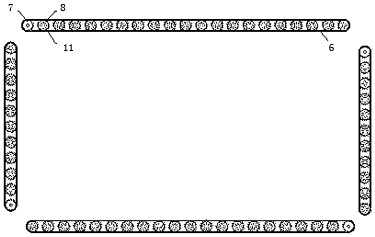

[0028] The overall structure of the production device adopted by the present invention is as follows: figure 1 As shown, it includes a tension frame 1, a yarn collection mechanism 2, an inner and outer mold forming mechanism 3, an immersion pool 4 and a curing device 5 arranged sequentially from top to bottom, and the yarn collection mechanism is as follows figure 2 , 3 , shown in 4, comprise chain mechanism 6, motor drive gear 7 and some strand gears 8, wherein, each strand gear center all has some threading holes 11, and motor drive gear drives a strand gear to rotate by chain belt , the yarn 9 in the tension frame passes through the threading hole in the skein gear, and enters the immersion pool.

[0029] Such as image 3 As shown, the chain mechanism is an endless chain, and a motor transmission gear is arranged in the endless chain.

[0030] Such as Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com