A New Type of High Voltage Overhead Dense Bus Arrangement System

A high-voltage overhead and busbar layout technology, which is applied in the spatial arrangement/configuration of cables, can solve problems such as short circuits, and achieve the effects of avoiding short circuit accidents and reducing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

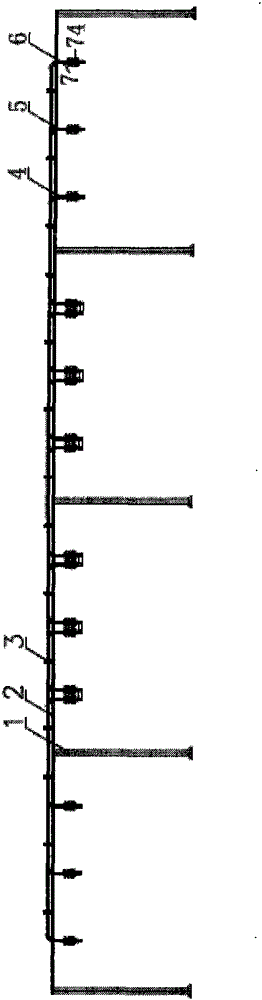

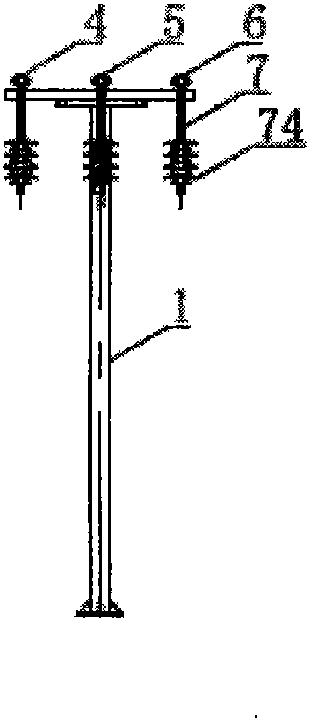

[0018] see figure 1 and image 3 , the new high-voltage overhead dense bus layout system of the present invention includes a column 1, a bracket 2, a hoop 3, a phase A capacitive insulating bus bar 4, a B phase capacitive insulating bus bar 5, a C phase capacitive insulating bus bar 6, and the bracket 2 is set Above the column 1, the A-phase capacitive insulating bus bar 4, the B-phase capacitive insulating bus bar 5, and the C-phase capacitive insulating bus bar 6 are all composed of several U-shaped capacitive insulating bus bars 7, and the U-shaped capacitive insulating bus bar 7 includes The straight middle part 7A and the two arm parts 7B formed by bending from the two ends of the straight middle part 7A to the same side respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com