Single-tip cross arm and transmission tower

A transmission tower and cross-arm technology, applied in the field of transmission insulation equipment, can solve problems such as waste, increased cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

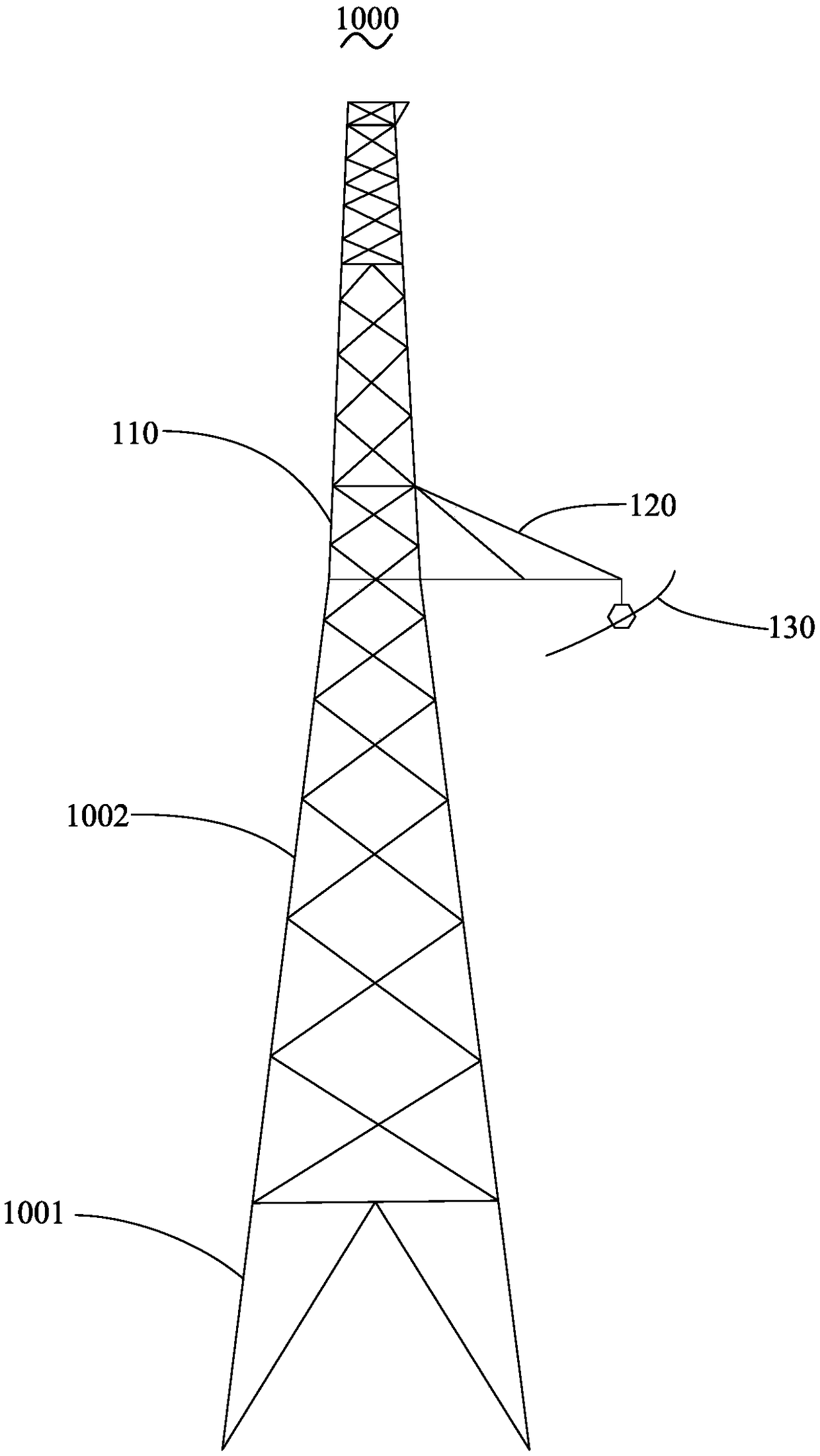

[0024] like figure 1 As shown, the transmission tower 1000 of this embodiment is a lattice steel tower, which has a tower leg 1001, a tower body 1002 connected above the tower leg 1001, and a tower head 110 connected above the tower body 1002, and the tower head 110 is provided with There is a single pointed cross arm 120, and the single pointed cross arm 120 is used to hang the wire 130, and the section of the tower head 110 along the horizontal plane is a square. The tower legs 1001, the tower body 1002 and the tower head 110 are all made of angle steel.

[0025] Of course, the present invention is not limited thereto. In other embodiments, the power transmission tower 1000 may also use other metal materials such as iron, or may also use composite materials. The section of the tower head 110 along the horizontal plane may also be rectangular.

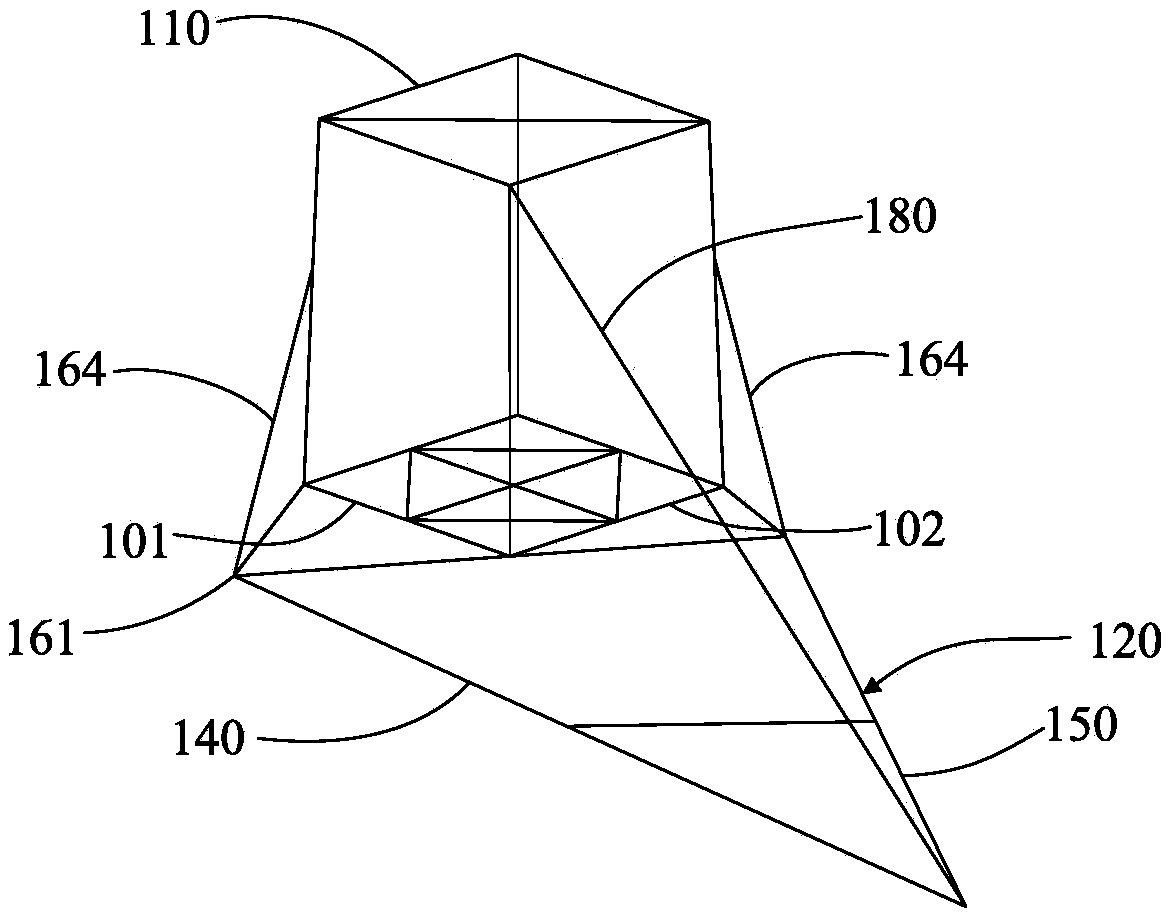

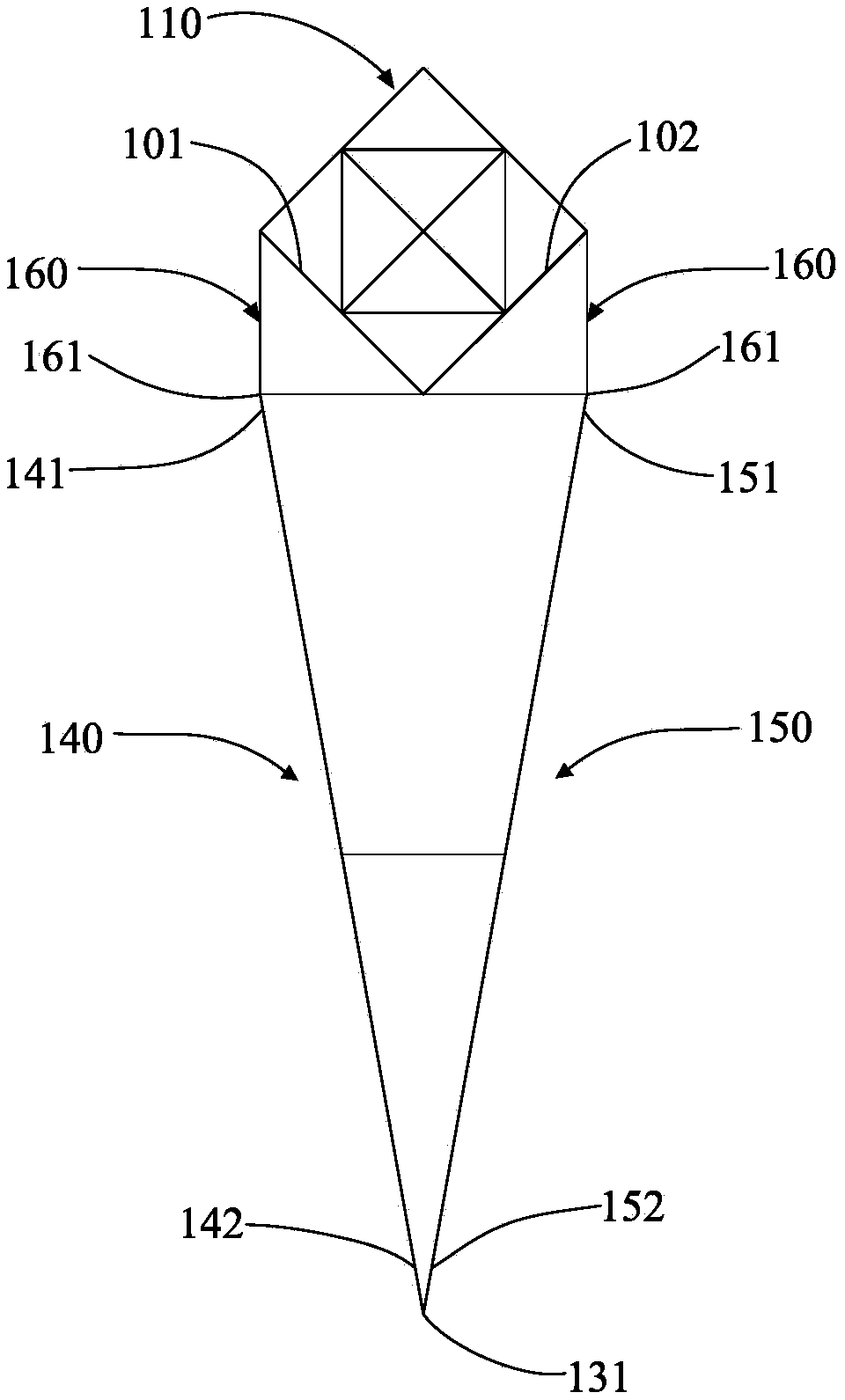

[0026] like figure 2 , image 3 As shown, in this embodiment, the single-pointed cross-arm 120 has two sets of cross-arm insula...

Embodiment 2

[0044] see Figure 5 , the structure of the single-pointed cross-arm 220 in this embodiment is basically the same as that of the single-pointed cross-arm 120 in Embodiment 1, the difference is that the first cross-arm insulator 240 and the second cross-arm insulator 250 are one Composed of composite insulators, without auxiliary cross-arm insulators. Moreover, the first cross-arm insulator 240 is directly connected to the midpoint of the first angle steel 201 , so as to be connected to the tower head 210 , without setting auxiliary arms and auxiliary cable-stayed insulators. The structure of the second cross-arm insulator 250 is the same as that in the first embodiment.

[0045] Of course, the present invention is not limited thereto. In other embodiments, the second cross-arm insulator 250 may also be directly connected to the midpoint of the second angle steel. Or both the first cross-arm insulator 240 and the second cross-arm insulator 250 are directly connected to the mi...

Embodiment 3

[0047] see Image 6 , the structure of the single-pointed cross-arm 320 in this embodiment is basically the same as that of the single-pointed cross-arm 120 in Embodiment 1, the difference is that a second cable-stayed insulator 390 and a third cable-stayed insulator are also provided 391, one end of the second cable-stayed insulator 390 is connected to the connection between the first cable-stayed insulator 380 and the tower head 310, and the other end of the second cable-stayed insulator 390 is connected to the first cross-arm insulator 340 and the auxiliary cross-arm insulator 370 Junction. One end of the third cable-stayed insulator 391 is connected to the connection between the first cable-stayed insulator 380 and the tower head 310, and the other end of the third cable-stayed insulator 391 is connected to the connection between the second cross-arm insulator 350 and the auxiliary cross-arm insulator 370 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com