Automation-based metal pipe bending device

A technology for bending devices and metal pipes, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems that metal pipes cannot be bent and affect the performance of metal pipes, and achieve the effect of avoiding dent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

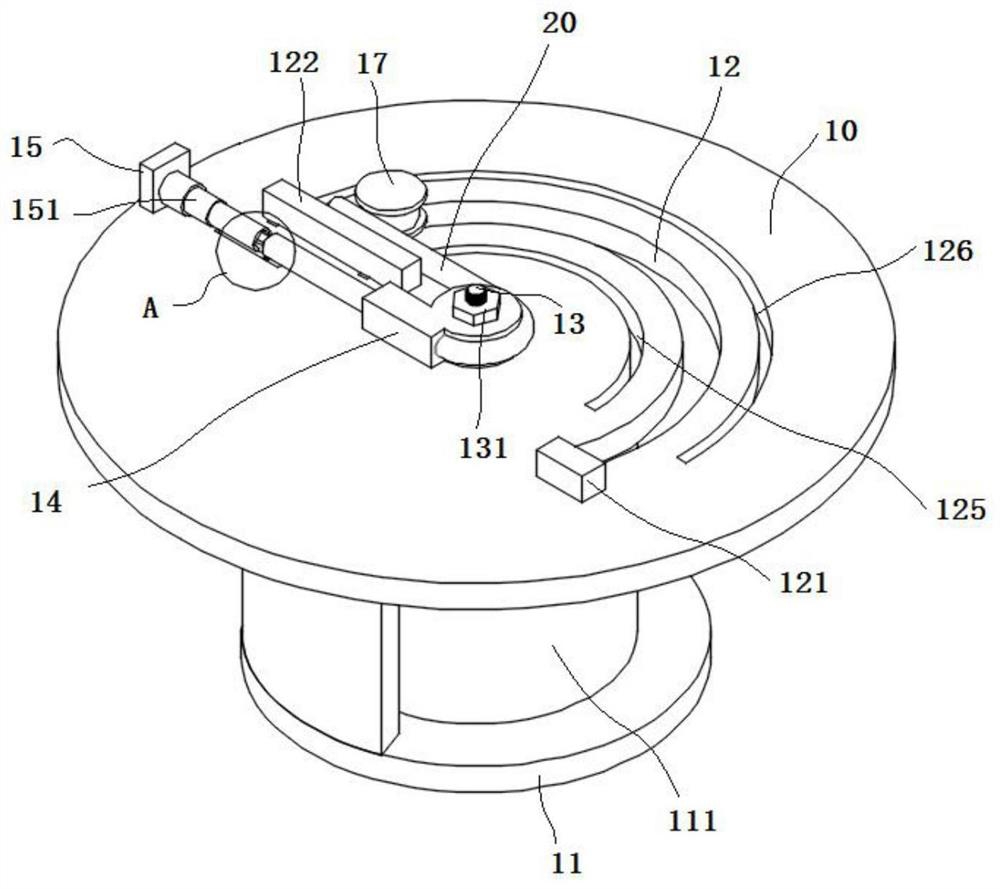

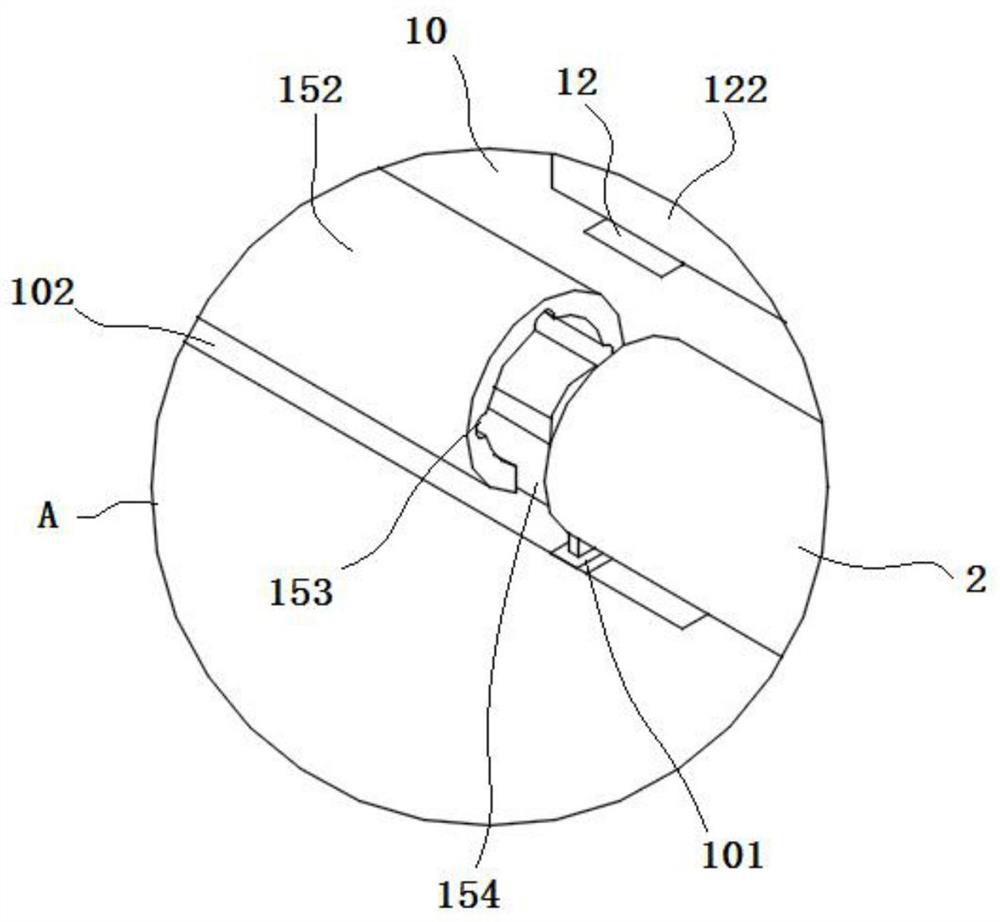

[0051] see as Figure 1-7As shown, a metal pipe bending device based on automation includes a bending system 100. The bending system 100 includes a working platform 1. A bending fixed end 14 is installed at the center of the upper surface of the working platform 1. The working platform 1 The bottom side is connected with a support plate 11 through a fixed side plate 112; a bending motor 111 is fixed on the support plate 11, and a bending driver is fixed on the output shaft of the bending motor 111, and the bending driver includes a bending motor 111 output The fixed part 16 that the shaft is matched and connected, one side of the fixed part 16 is connected with a swing arm 161, the other end of the swing arm 161 is fixed with a bending shaft 162, and the top of the bending shaft 162 is connected with a bending head 19 or folding Bend ends.

[0052] see as figure 1 and 4 As shown, the bending end includes a connecting end 17 fixed on the top of the bending shaft 162. The con...

Embodiment 2

[0067] refer to Figure 1-22 As shown, a metal pipe bending equipment includes a cutting system 500, a bending system 100, a feeding system and an unloading system.

[0068] see as figure 1 The bending system 100 shown includes a working platform 1, and a bending fixed end 14 is installed in the center of the upper surface of the working platform 1; the bottom side of the working platform 1 is connected with a support plate 11 through a fixed side plate 112; A bending motor 111 is fixed, and a bending driver is fixed on the output shaft of the bending motor 111; the bending driver includes a fixing part 16 that is matched and connected with the output shaft of the bending motor 111, and a pendulum is connected to one side of the fixing part 16 The other end of the arm 161 and the swing arm 161 is fixed with a bending shaft 162 , and the top end of the bending shaft 162 is connected with a bending head 19 or a bending end.

[0069] see as figure 1 and 4 As shown, the bendin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com