A device for an actuator that does not change the direction of the lug and realizes stepless adjustment of the zero length

A stepless adjustment and actuator technology, applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve the problem of inconvenient operation of zero position adjustment, and achieve the effect of simple structure, light weight, and precise adjustment and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

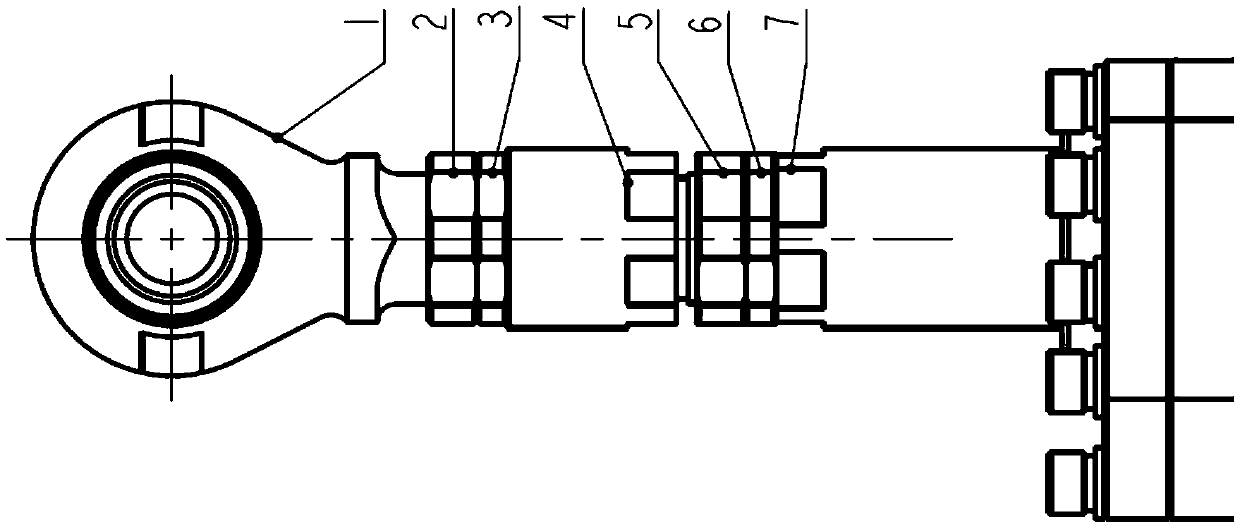

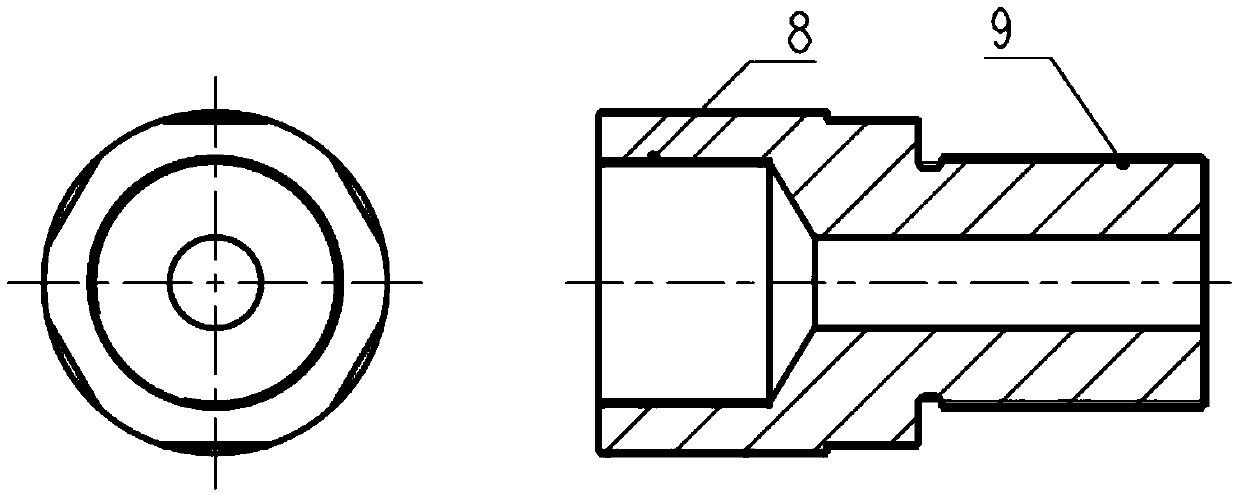

[0026] A device of the present invention that does not change the direction of the lugs and realizes stepless adjustment of the zero length is installed between the front lugs and the end face of the lead screw and passes through thick nuts I (2), thin nuts I (3), thick The nut II (5) and the thin nut II (6) realize the locking of the device of the present invention. A blind hole is arranged at one end of the first cylindrical section, and a through hole smaller than 2 times the small diameter of the thread is drilled to reduce weight. A left-handed screw is provided in the blind hole. Internal thread, there is a right-handed external thread on the outside of the second cylindrical section, the major diameter of the left-handed internal thread is the same as that of the right-handed external thread, the pitch of the threads at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com