Pipe structure

A technology for pipe fittings and pipe assemblies, which is applied in the field of improvement of pipe fitting structures, can solve the problems of affecting support strength and service life, increase connecting parts, increase set steps, etc. The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

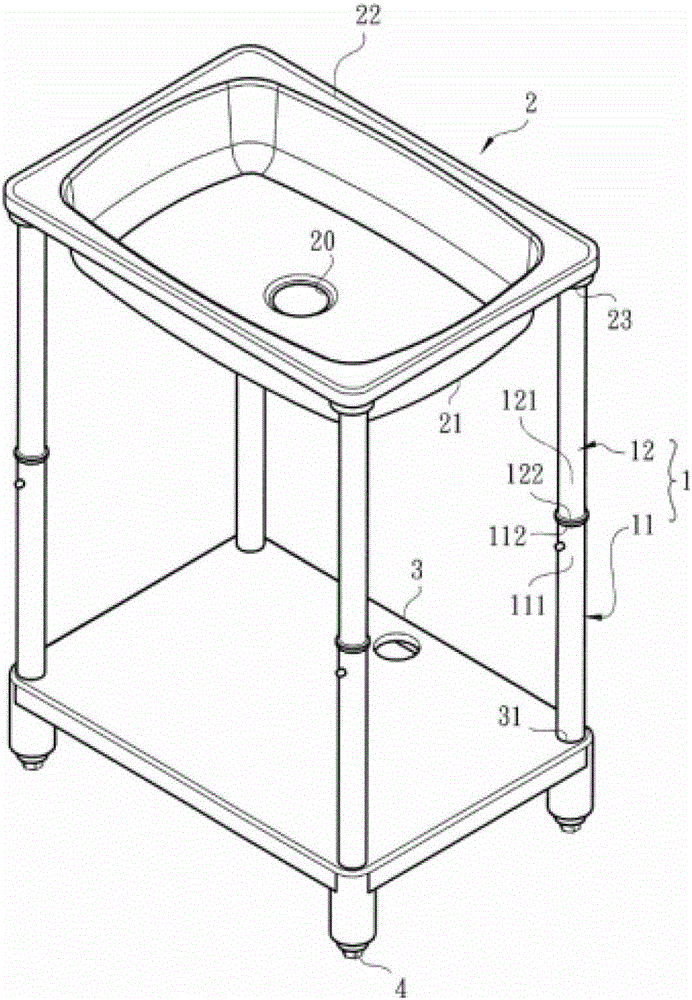

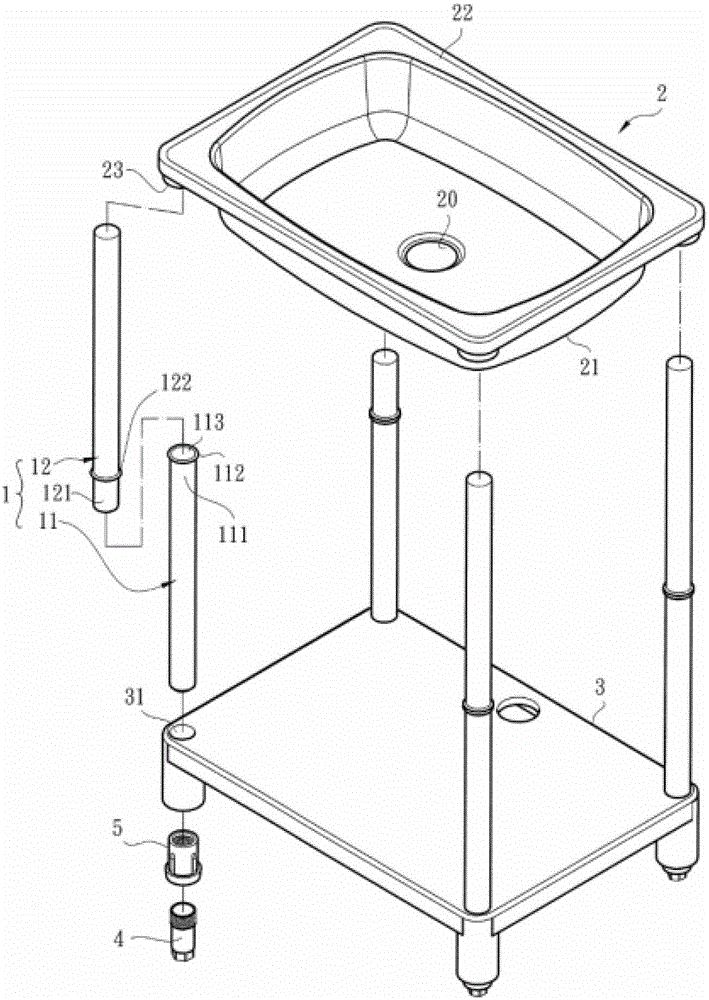

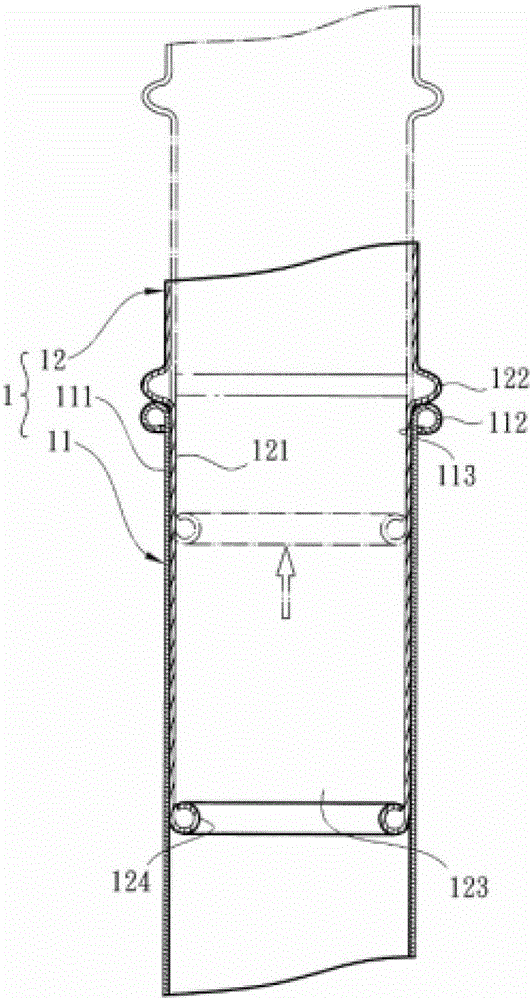

[0078] Please refer to Figure 1 to Figure 3 , which discloses the drawings of the first embodiment of the present invention, wherein, figure 1 It is a perspective view of the first embodiment of the present invention, figure 2 for figure 1 three-dimensional exploded view, image 3 for figure 1 Partial sectional view of embodiment.

[0079] The structure of the pipe fittings of the present invention is illustrated by the above drawings, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com