Porous polyolefin film

A polyolefin membrane and porosity technology, applied in the field of polyolefin microporous membranes, can solve the problems of pore blockage, porosity reduction, melting point rise, etc., and achieve the effect of improving shutdown characteristics and excellent foreign body resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

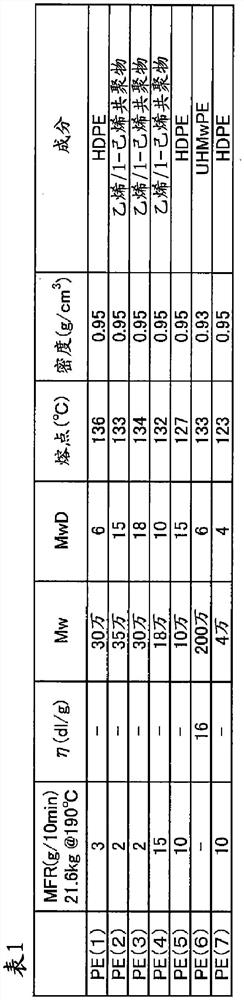

Embodiment 1

[0169] As a raw material, a Mw of 0.30×10 6, MwD (Mw / Mn) is 18, MFR is 2.0 g / 10min, the ethylene / 1-hexene copolymer (PE (3) described in Table 1) that has melting point of 134 degreeC. Add 70% by mass of liquid paraffin to 30% by mass of the polyethylene composition, further, add 0.5% by mass of 2,6-di-tert-butyl-p-cresol and 0.7% by mass based on the mass of polyethylene in the mixture % tetrakis[methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate]methane was mixed as an antioxidant to prepare a polyethylene resin solution.

[0170] The obtained polyethylene resin solution was put into a twin-screw extruder, kneaded at 180° C., supplied to a T-die, and extruded into a sheet so that the final microporous film thickness became 20 μm, and then extruded into a sheet. The output was cooled with a cooling roll controlled at 25° C. to form a gel-like sheet.

[0171] The gel-like sheet obtained is passed through a tenter stretching machine at 115° C. along the length directi...

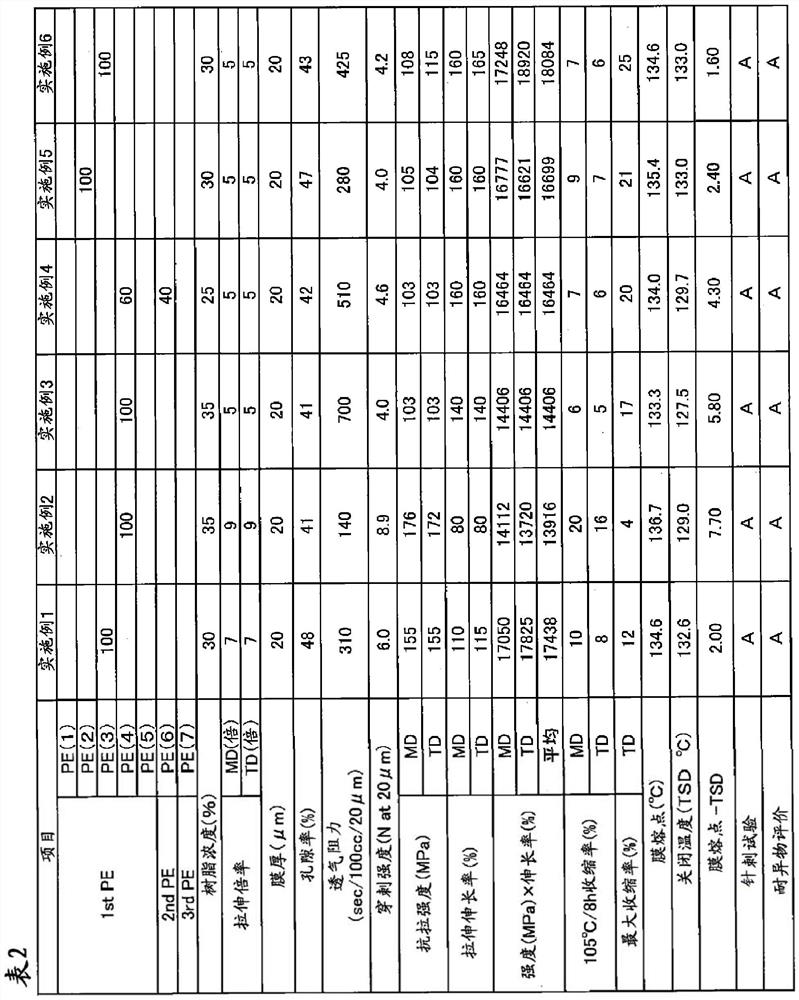

Embodiment 2~6

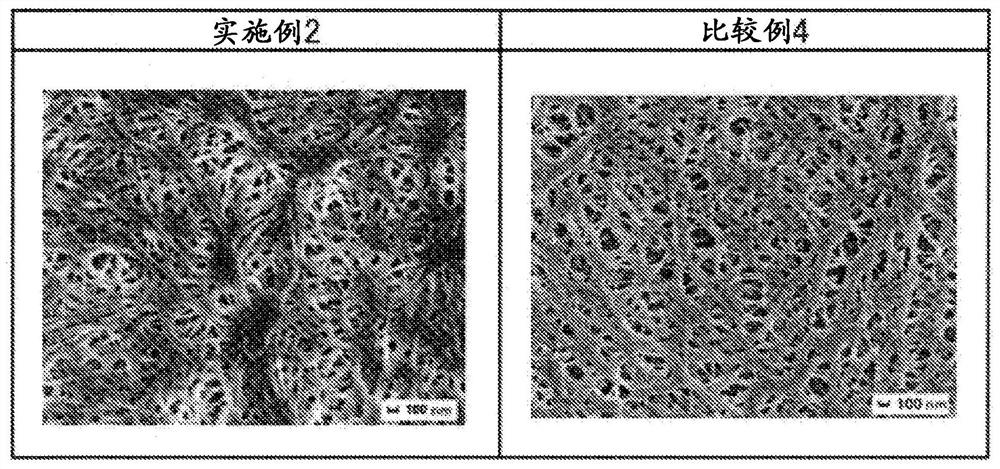

[0176] A polyolefin microporous membrane was produced in the same manner as in Example 1, except that the raw material described in the raw material characteristics (Table 1) of the polyolefin microporous membrane was changed as shown in Table 2. Table 2 shows the evaluation results of the obtained polyolefin microporous membrane.

Embodiment 5

[0188] In Example 5, since the molecular weight of the raw material was increased compared with Example 1, it is considered that although it has high toughness, the density of linking molecules is increased, the movement of crystals is suppressed, and as a result, the shutdown temperature is increased. However, since a raw material lower than the melting point of the raw material used in Example 1, such as 133° C., was used in addition to the entanglement control of the amorphous portion using the ethylene / 1-hexene copolymer, a low shutdown temperature was maintained. , has good porosity and needle penetration test and foreign body resistance.

[0189] In Comparative Example 1, a good porosity was obtained by using a raw material with a high melting point, but the use of relatively small molecular weight HDPE was stretched at a high ratio, so it was highly oriented, and as a result, the elongation decreased due to high strength. to good toughness. In addition, as a result of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com