Rotary heat conduction oil boiler and tubular dryer integrated device

A heat-conducting oil boiler and dryer technology, which is applied in the fields of coal chemical industry, electric power and machinery, can solve the problem of lignite dehydration, drying technology that cannot meet the needs of the industry, the best quality improvement effect, and internal water that cannot be effectively removed in depth, etc. problems, to achieve the effect of reducing the cost of softening treatment, avoiding heat energy loss, and reducing long-term consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

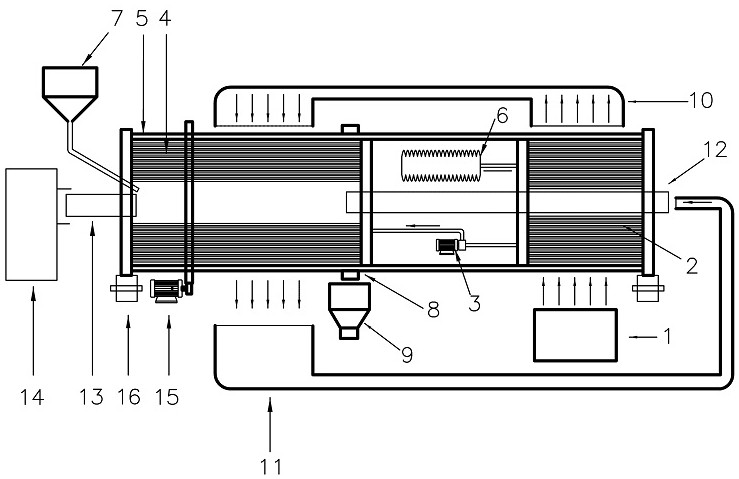

[0023] In order to understand technical characterictic of the present invention, below in conjunction with accompanying drawing figure 1 Specific embodiments of the present invention will be described.

[0024] The burner (1) used in the integrated device of the rotary heat-conducting oil boiler, tube and dryer can be any of pulverized coal, fuel oil and gas burners. Use the burner to generate high-temperature, high-speed oxygen-deficient flow to heat the heat-transfer medium heat-transfer oil in the tube bundle of the rotary heat-transfer oil boiler (2), and control the temperature of the heat-transfer oil within the optimal range of lignite dehydration between 280°C and 300°C. Use the heat transfer oil circulation pump (3) to directly inject high temperature heat transfer oil into the tube bundle of the tube dryer (4). The heat carried by the heat transfer oil is transferred to the lignite in the cylinder of the tube dryer (4) through the tube bundle of the tube dryer (4). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com