Modular wind tower with multi-stage prestressing

A prestressed, wind tower technology, applied in the installation/support of wind turbine configurations, towers, wind power generation, etc., can solve problems such as damage, large stress concentration, and difficulty in re-applying prestressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

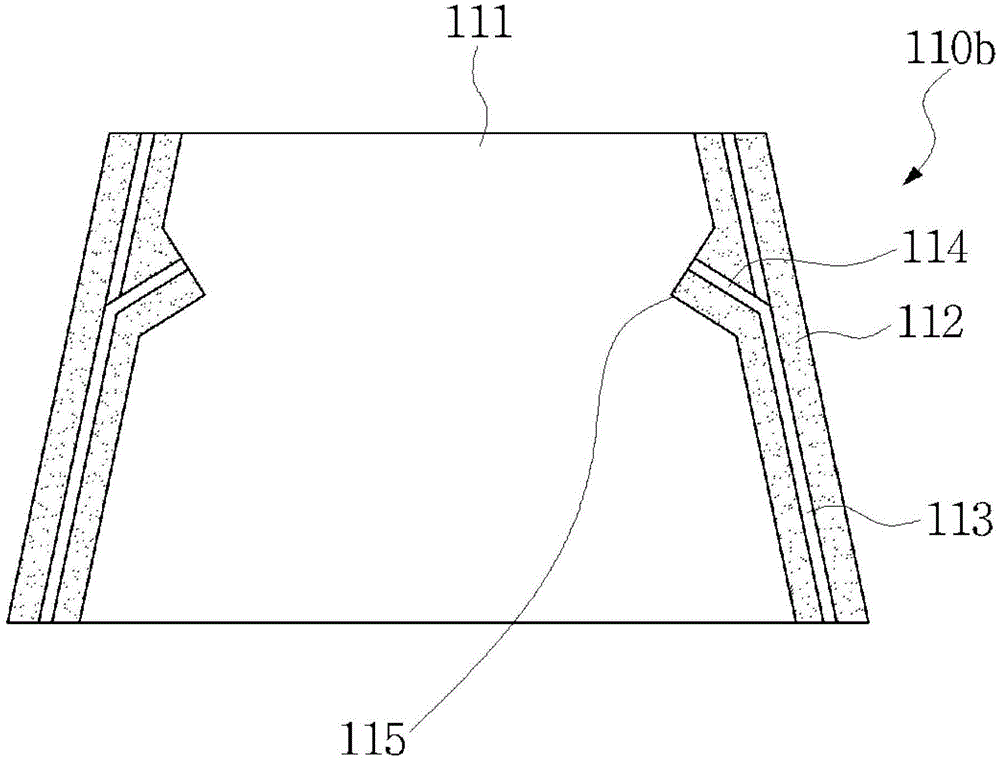

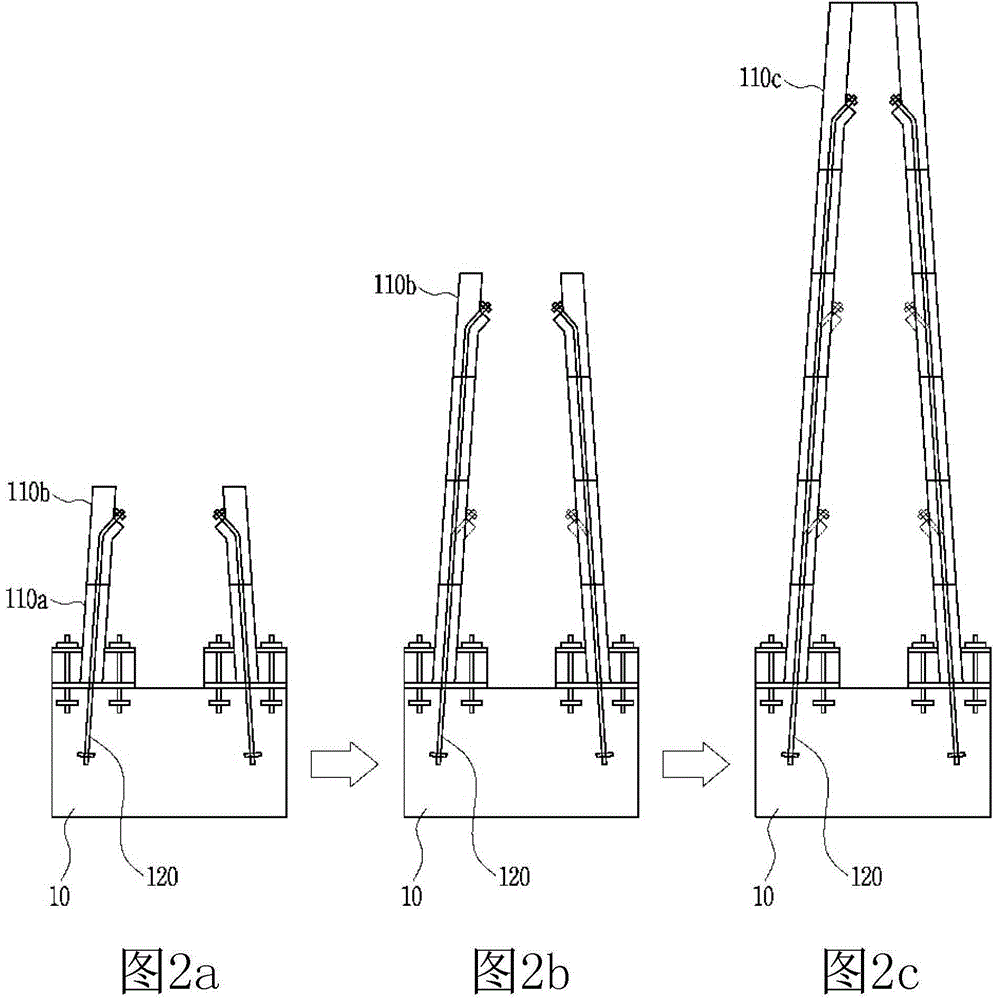

[0033] The present invention relies on the multi-stage prestressed modular wind power tower to be stacked and assembled into a wind power tower by a plurality of modules that are prestressed through internal prestressed tendons. The above modules include: a plurality of stacked modules with prestressed tendons running through Tendon; a plurality of stretching modules, having a stretching introduction part through which the prestressing tendon is penetrated and the prestressing tendon is stretched and placed.

[0034] That is, in the present invention, modules are stacked to form a wind tower and a plurality of tensile modules are arranged among the stacked modules, so that prestress is not only applied to the uppermost end, but also prestress is applied in a multi-stage manner to prevent stress from concentrating on a specific area. position for structural stability.

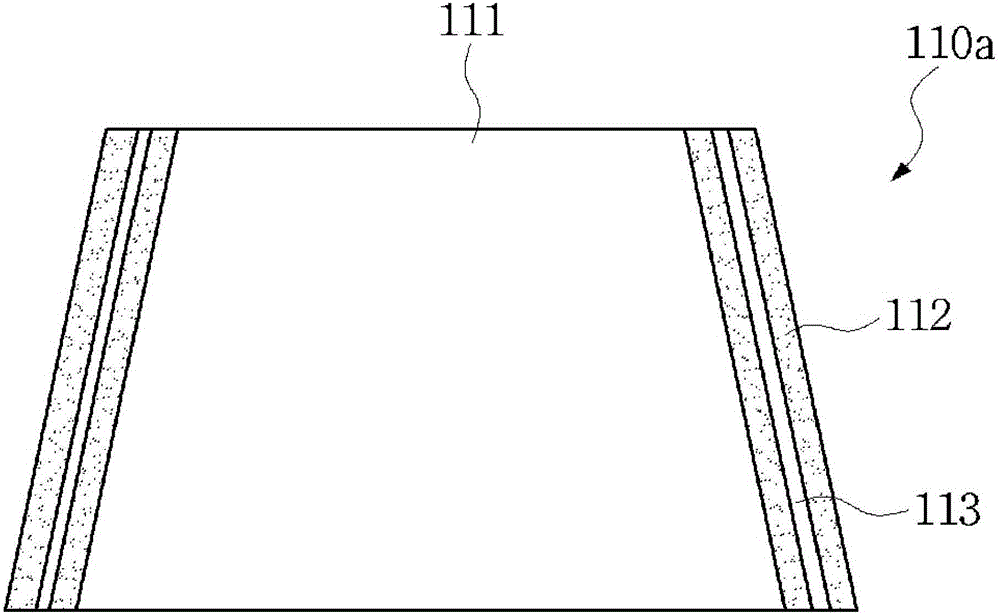

[0035] Moreover, the above-mentioned module includes a concrete part constituting the main body and a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com