A permanent magnet liquid-cooled retarder with multi-head structure

A retarder, permanent magnet fluid technology, applied in the direction of permanent magnet clutch/brake, etc., can solve the problems of retarder work failure, poor work reliability, easy to throw out magnets, etc., to achieve high safety performance, light rotor weight , the effect of small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

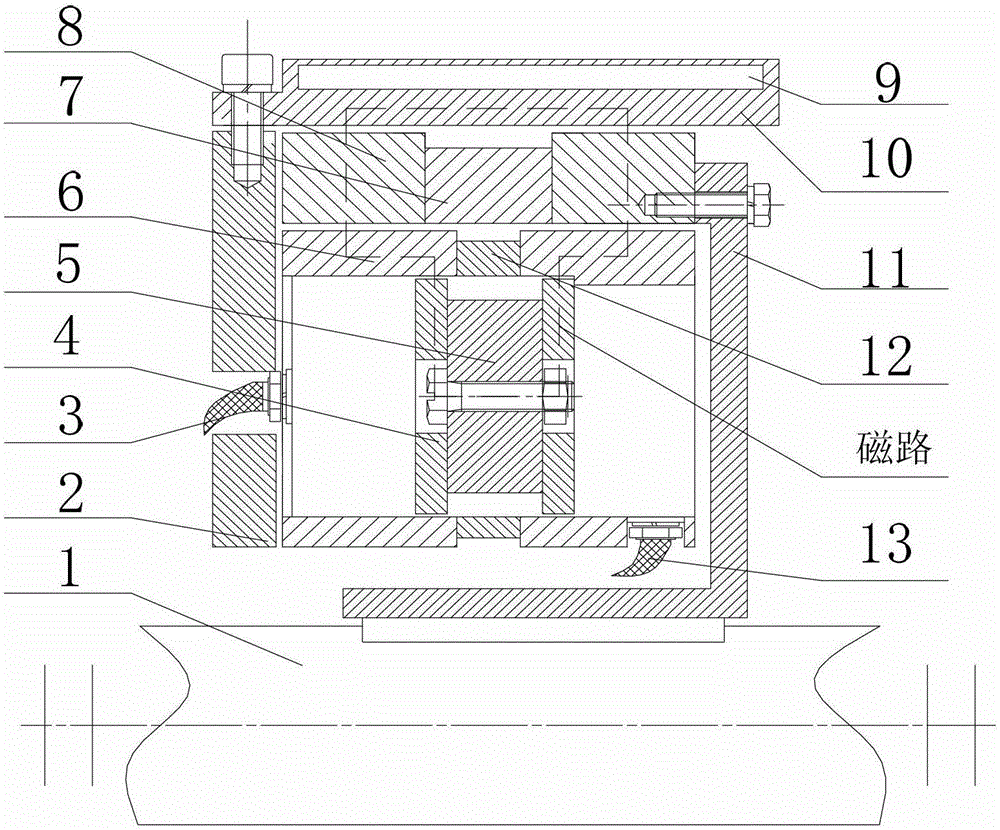

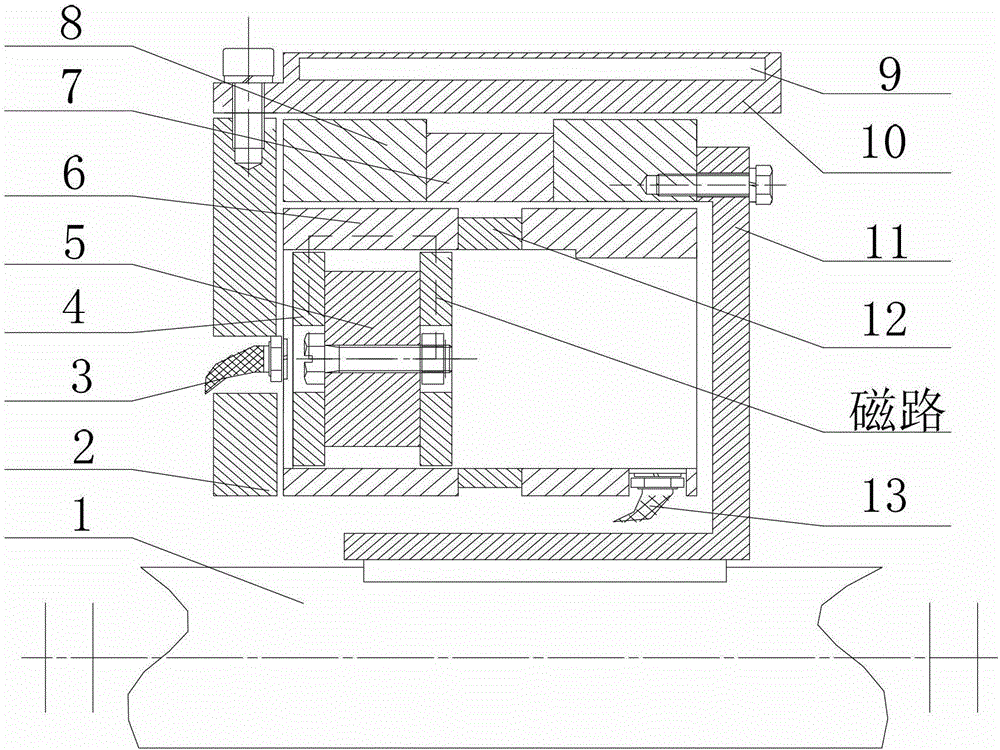

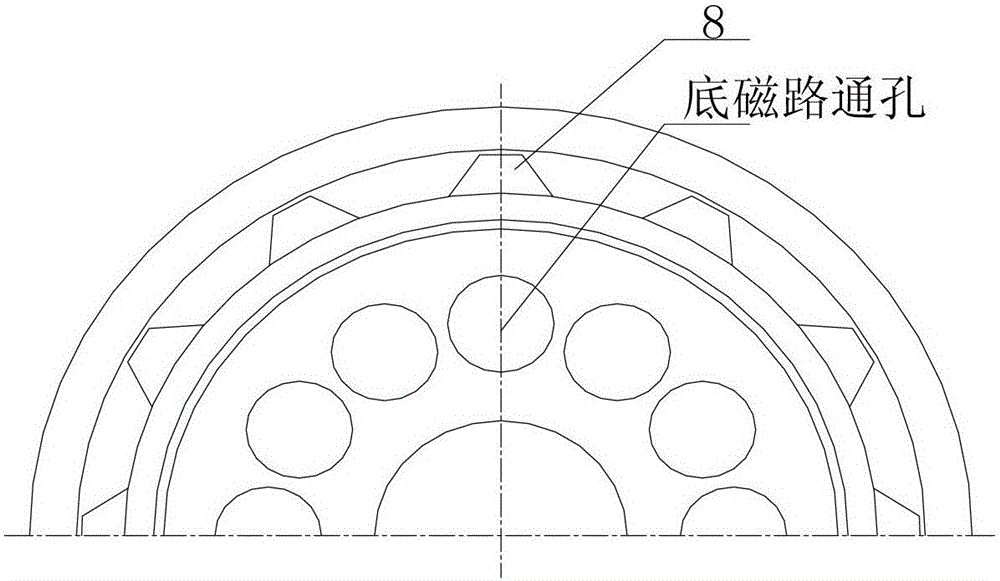

[0016] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. like figure 1 and figure 2 As shown, one end of the rotor arm 11 in the embodiment of the present invention is connected to the transmission shaft 1 through a key, and the other end of the rotor arm 11 is connected to the retarder rotor (including the two rotor salient poles 8 and the rotor non-magnetic conductive ring 7) through screws. A rotating part is formed; a number of permanent magnets 5 are evenly distributed in the through hole of the bottom magnetic circuit 6, the permanent magnet 5 can move axially in the through hole, and the cylindrical permanent magnet 5 and the magnetic conductive blocks 4 at both ends are connected by bolts. The connection can move along the axial direction with the permanent magnet 5 in the through hole of the bottom magnetic circuit 6; the upper air inlet 3 is installed on the left circular end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com