A washing machine and its control method

A technology of washing equipment and control method, which is applied to the control device of washing machine, washing device, other washing machines, etc., which can solve the problems of reducing the high-temperature washing efficiency of washing machine and the inability to realize the separation of water and electricity, so as to speed up the washing time and eliminate electrical safety hazards , use the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

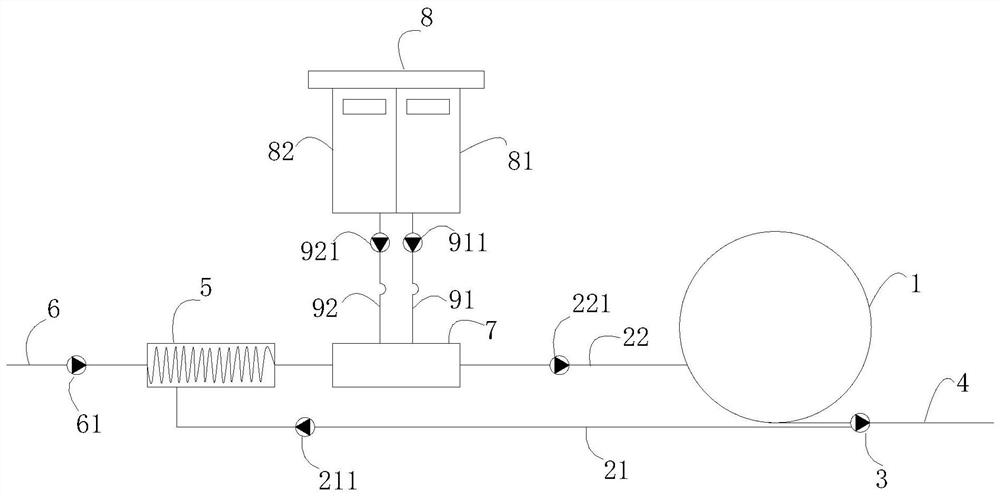

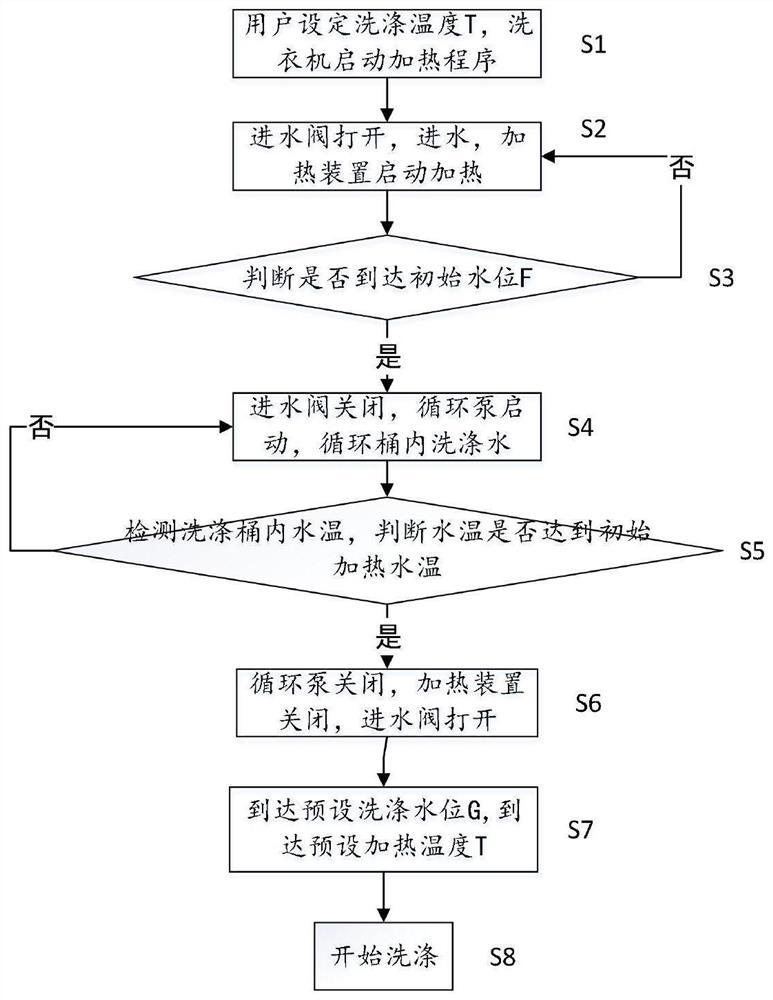

[0061] like figure 1 The shown detergent comprises a washing bucket 1, the water outlet at the bottom of the washing bucket 1 is connected to a circulation pipeline at the mouth of the washing bucket 1, and the circulation pipeline includes a circulation outlet pipe 21 and a circulation return pipe 22. The heating device 5 is connected between the water outlet pipe 21 and the circulating water return pipe 22 . The circulation outlet pipe 21 is provided with a control valve of the circulation outlet pipe 21 , and the circulation return pipe 22 is provided with a circulation return pipe control valve 221 and a circulation pump 3 . It also includes a water inlet pipeline 6, which is connected to the heating device 5, and a water inlet valve 61 is arranged on the water inlet pipeline 6. In addition, the washing bucket 1 also includes a dispenser box 8, the dispenser box 8 has a detergent chamber 82 and a softener chamber 81, and the detergent chamber 82 and the softener chamber 8...

Embodiment 2

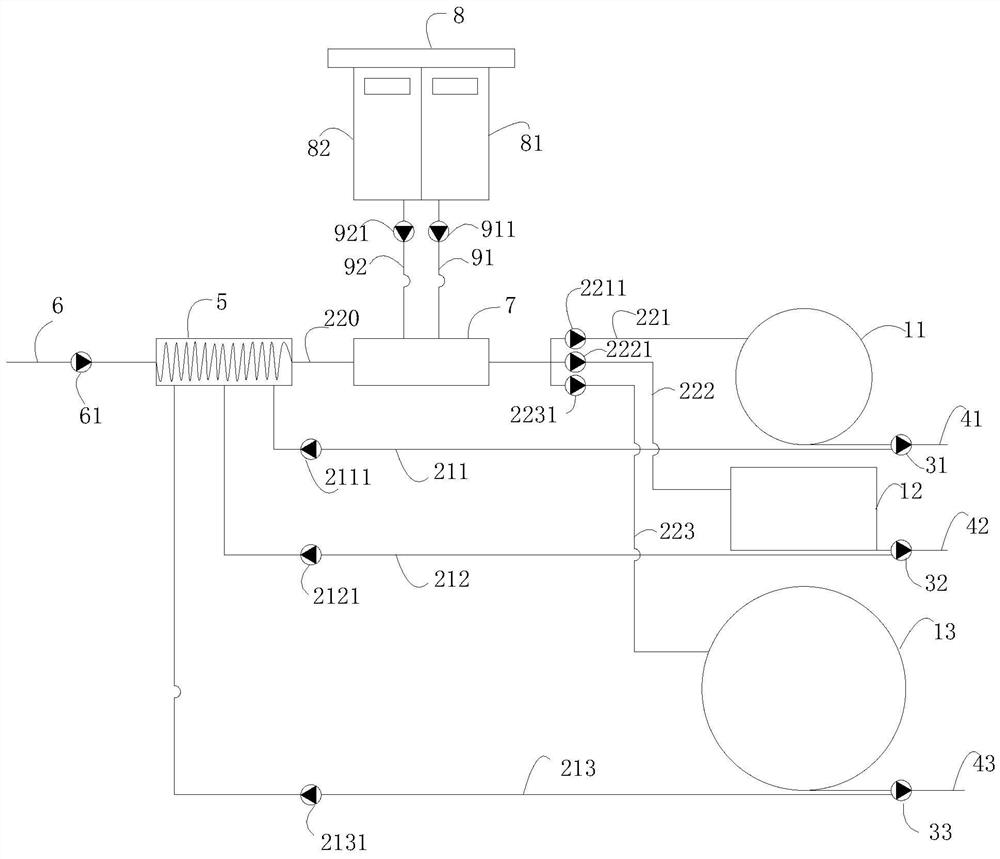

[0084] This embodiment discloses a washing device with multiple washing tubs on the basis of Embodiment 1. The circulating water circuit includes multiple circulating return pipes and multiple circulating return pipes, and the multiple circulating return pipes and multiple circulating return pipes The water pipes are connected to a plurality of washing tubs in one-to-one correspondence; each circulating water outlet pipe and circulating water return pipe are respectively connected to the heating device 5 .

[0085] like figure 2 The washing equipment shown includes a first washing tub 11 , a second washing tub 12 and a third washing tub 13 . It also includes a first circulation outlet pipe 211 and a first circulation return pipe 221 corresponding to the first washing tub 11; a second circulation outlet pipe 212 and a second circulation return pipe 222 corresponding to the second washing tub 12; The third circulating water outlet pipe 213 and the third circulating water retur...

Embodiment approach 1

[0100]Specific embodiment one, the initial water temperature C of the second washing tub 12 and the third washing tub 13 are different, the initial water temperature C corresponding to the second washing tub 12 is 70°C, and the initial water temperature corresponding to the second washing tub 12 is 90°C, then The water temperature of the second washing bucket 12 and the third washing bucket 13 can be heated to 70°C by circulating heating first, and then the circulating heating of the first washing bucket 11 and the second washing bucket 12 can be stopped, and the water inlet pipeline 6 and the second circulation can be controlled. The path of the return water pipe 222 is turned on, and the second washing tub 12 is filled with water up to the preset water level of 400L. At this time, the water temperature of the second washing tub 12 reaches 60°C; The path is turned on, and the third washing bucket 13 is cyclically heated, and the water temperature of the third washing bucket 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com