Compounding method of melt-blown cloth and composite melt-blown cloth prepared thereby

A melt-blown cloth and the resulting technology are applied in chemical instruments and methods, non-polymer organic compound adhesives, synthetic resin layered products, etc. Uniform coating and other problems, to achieve the effect of maintaining filtration efficiency and air resistance, improving composite strength, and easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

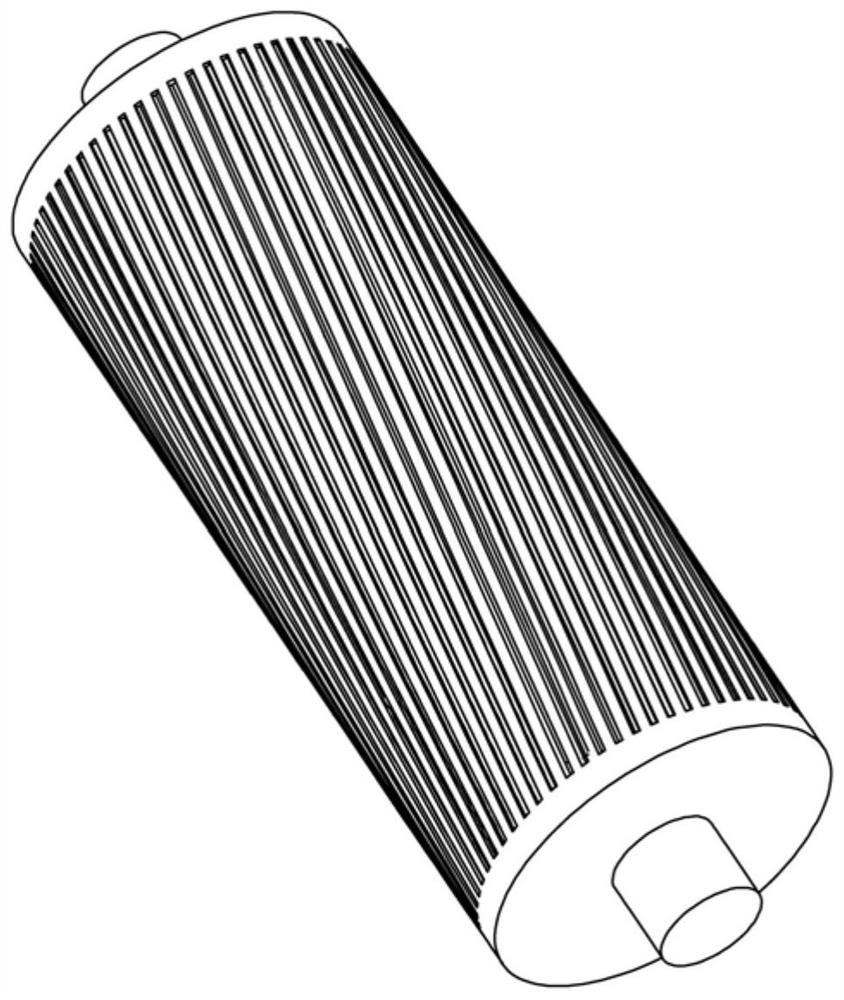

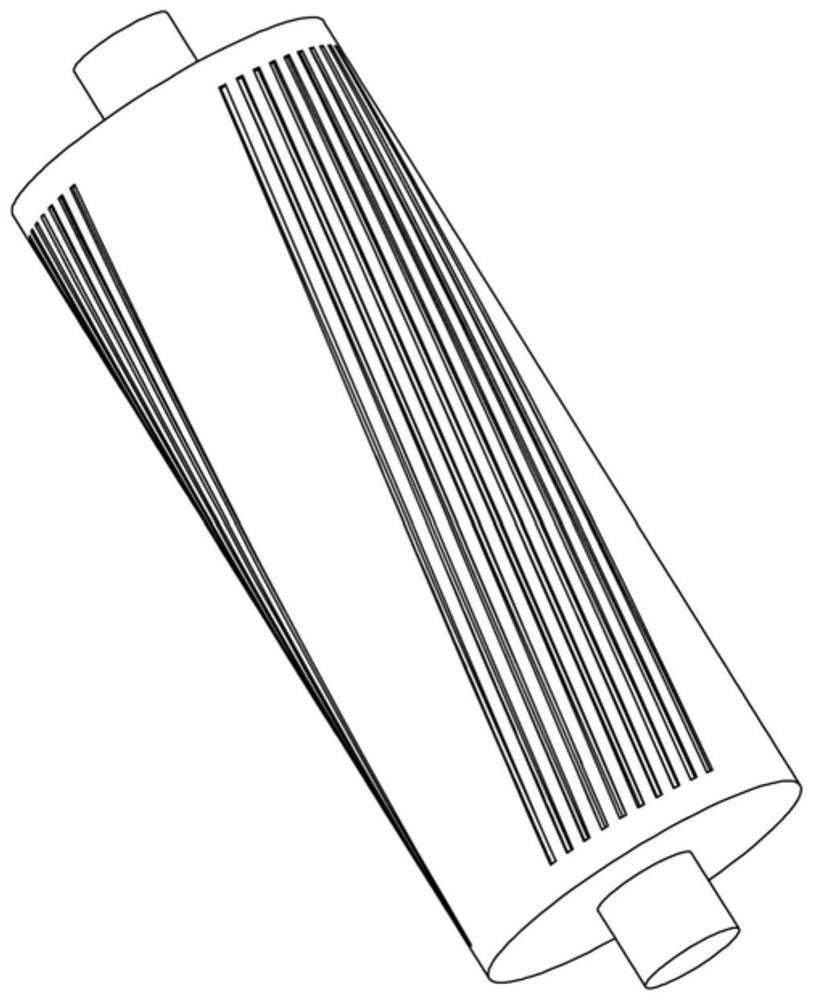

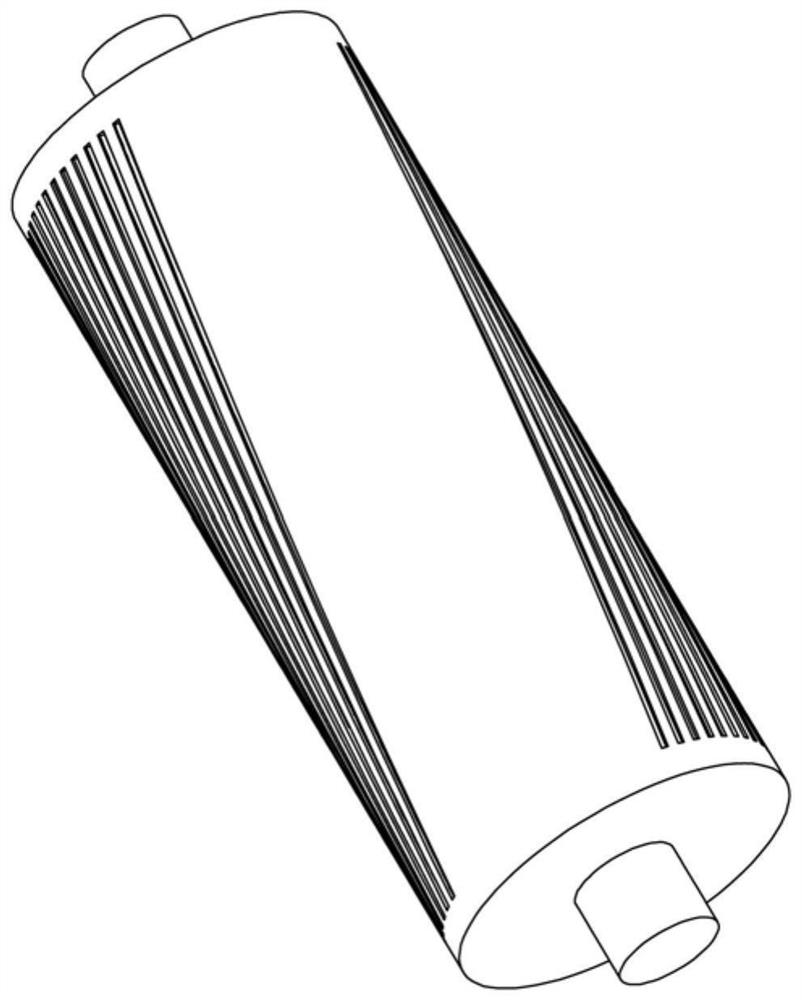

Image

Examples

Embodiment 1

[0046] According to the present invention, adopt following composite method to prepare composite meltblown cloth:

[0047] (1) Use a coating roller to roll-coat the water-based adhesive on the melt-blown cloth, and then use a pressure roller to superimpose it on the polypropylene non-woven fabric;

[0048] Wherein, the coating roller is provided with a plurality of parallel grooves extending to both ends of the roller in an evenly distributed manner on the surface of the roller, the depth of the grooves is 25 μm, the width of the notches is 70 μm, and the spacing is 0.6 mm , and the angle between the extension direction of the groove and the rotation direction of the coating roller is 45°,

[0049] Wherein, the water-based adhesive comprises 5% by weight of water-based acrylic acid, 2% by weight of polyethylene glycol 200 and 93% by weight of water, and its coating amount is 8g / m 2 , and the coating thickness is 3 μm.

[0050] (2) Dry the product of step (1) at 50° C. for 20...

Embodiment 2

[0052] According to the present invention, adopt following composite method to prepare composite meltblown cloth:

[0053] (1) Use a coating roller to roll-coat the water-based adhesive on the melt-blown cloth, and then use a pressure roller to superimpose it on the polypropylene non-woven fabric;

[0054] Wherein, the coating roller is provided with a plurality of parallel grooves extending to both ends of the roller in an evenly distributed manner on the surface of the roller, the depth of the grooves is 20 μm, the width of the notches is 75 μm, and the spacing is 0.3 mm , and the angle between the extension direction of the groove and the rotation direction of the coating roller is 60°,

[0055] Wherein, the water-based adhesive comprises 4% by weight of water-based acrylic acid, 3% by weight of polyethylene glycol 200 and 93% by weight of water, and its coating amount is 8g / m 2 , and the coating thickness is 4 μm.

[0056] (2) Dry the product of step (1) at 40° C. for 24...

Embodiment 3

[0058] According to the present invention, adopt following composite method to prepare composite meltblown cloth:

[0059] (1) Use a coating roller to roll-coat the water-based adhesive on the melt-blown cloth, and then use a pressure roller to superimpose it on the polypropylene non-woven fabric;

[0060] Wherein, the coating roller is provided with a plurality of parallel grooves extending to both ends of the roller in an evenly distributed manner on the surface of the roller, the depth of the grooves is 30 μm, the width of the notches is 60 μm, and the spacing is 1 mm. And the angle between the extending direction of the groove and the rotating direction of the coating roller is 30°,

[0061] Wherein, the water-based adhesive comprises 6% by weight of water-based acrylic acid, 1% by weight of polyethylene glycol 200 and 93% by weight of water, and its coating amount is 8g / m 2 , and the coating thickness is 2 μm.

[0062] (2) Dry the product obtained in step (1) at 60° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com