Environment-friendly packaging bag and preparation method thereof

A packaging bag, environmental protection technology, applied in the field of packaging bags, can solve the problems of packaging bags that cannot meet high requirements, non-recyclable recycling costs, no shock absorption and buffering effect, etc., to meet market demand and reduce pollution. , the effect of fast drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

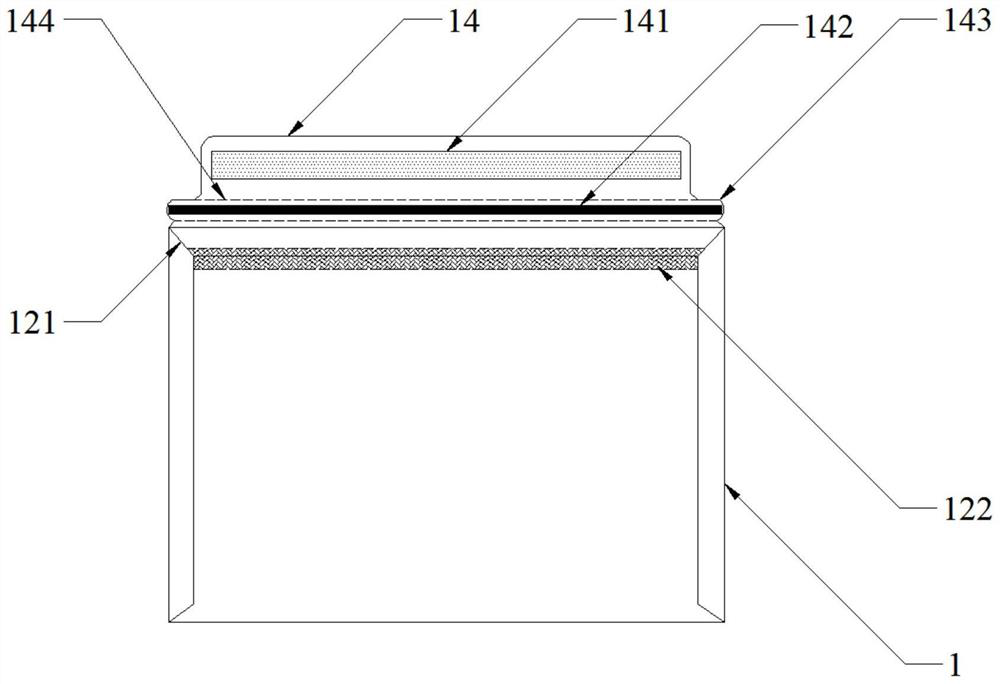

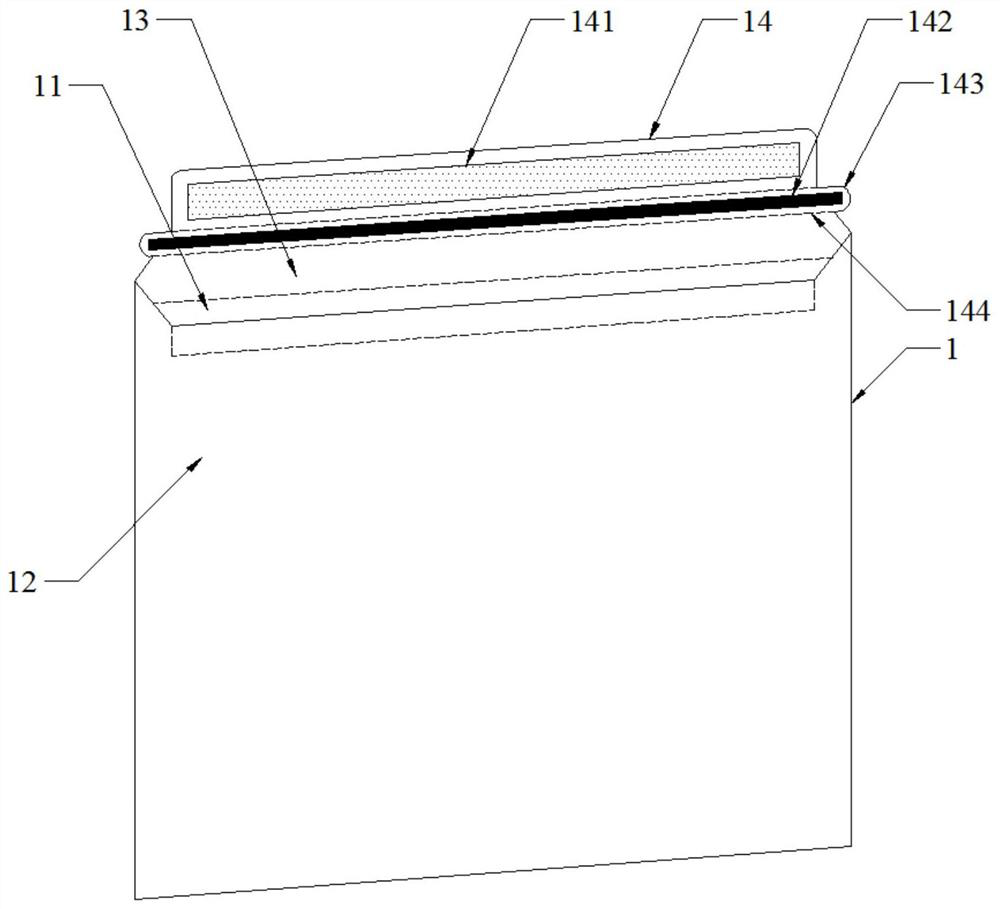

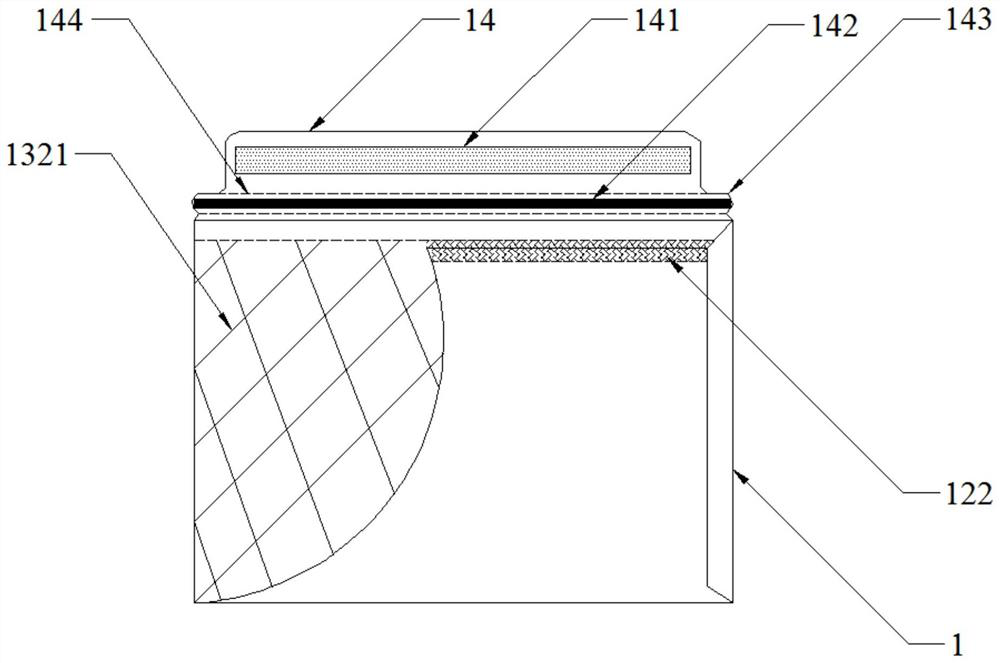

[0039] A method for preparing an environmentally friendly packaging bag, comprising a bag body 1, the material of the bag body 1 is a composite material composed of a face paper layer 131, a middle paper layer 133 and a bottom paper layer 132 arranged in sequence from outside to inside. Paper, the preparation method of this environment-friendly packaging bag comprises the steps:

[0040] 1) Rolling of the middle paper layer 133: the base paper is preheated and placed in the rolling device, and one side or both sides of the base paper layer are rolled into dots by rolling with buffer rollers in the rolling device. shaped cushioning protrusion 1331, and dry it at 120°C to obtain the middle paper layer 133; when preheating the base paper, triple preheaters are used for preheating, and the temperature for preheating is 85°C. The heating time is 0.6s;

[0041] 2) Die-cutting of the backing paper layer 132: a fully automatic cardboard die-cutting device is used to die-cut the surfa...

Embodiment 2

[0059] A method for preparing an environmentally friendly packaging bag, comprising a bag body 1, the material of the bag body 1 is a composite material composed of a face paper layer 131, a middle paper layer 133 and a bottom paper layer 132 arranged in sequence from outside to inside. Paper, the preparation method of this environment-friendly packaging bag comprises the steps:

[0060] 1) Rolling of the middle paper layer 133: the base paper is preheated and placed in the rolling device, and one side or both sides of the base paper layer are rolled into dots by rolling with buffer rollers in the rolling device. shaped cushioning protrusions 1331, and dry them at 135°C to obtain the middle paper layer 133; when the base paper is preheated, a triple preheater is used for preheating, and the temperature of the preheating is 88°C. The heating time is 0.63s;

[0061] 2) Die-cutting of the backing paper layer 132: a fully automatic cardboard die-cutting device is used to die-cut ...

Embodiment 3

[0080] A method for preparing an environmentally friendly packaging bag, comprising a bag body 1, the material of the bag body 1 is a composite material composed of a face paper layer 131, a middle paper layer 133 and a bottom paper layer 132 arranged in sequence from outside to inside. Paper, the preparation method of this environment-friendly packaging bag comprises the steps:

[0081] 1) Rolling of the middle paper layer 133: the base paper is preheated and placed in the rolling device, and one side or both sides of the base paper layer are rolled into dots by rolling with buffer rollers in the rolling device. shaped cushioning protrusion 1331, and dry it at 150°C to obtain the middle paper layer 133; when preheating the base paper, a triple preheater is used for preheating, and the temperature of the preheating is 90°C. The heat time is 0.675s;

[0082] 2) Die-cutting of the backing paper layer 132: a fully automatic cardboard die-cutting device is used to die-cut the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com