A kind of electronic material cutting cold processing fixed condensate and device

An electronic material and condensate technology, which is applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of difficulty in meeting the diversification of the size of the cut products, the temperature rise of the solidified layer of the cutting tool, and the unstable fixation. Achieve the effect of ensuring processing quality, reducing processing costs, and meeting the needs of energy conservation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the fixed condensate adopts dimethyl sulfoxide and 10 -6 mol / L thiocyanate, when cutting electronic ceramic materials, the electronic components will not be damaged due to the shaking of the plate during processing, and the scrap rate is low.

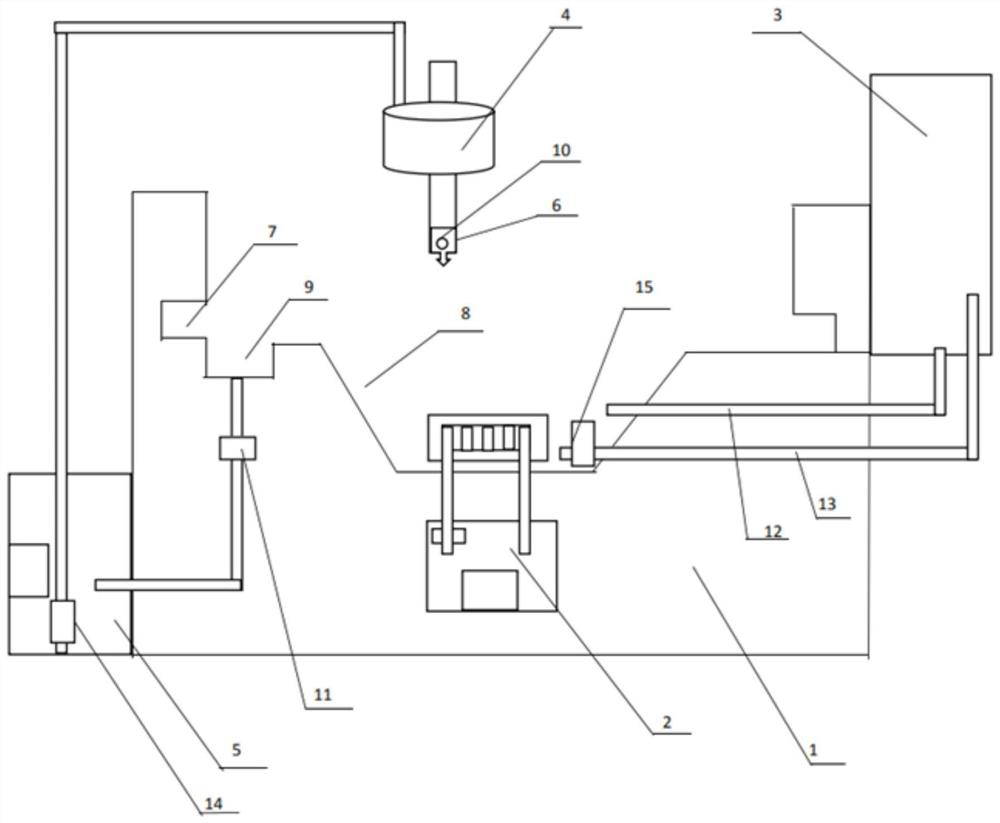

[0031] Lay the electronic material to be cut into the processing tank 7, and inject the condensate solution into the avoidance tank 8 through the fixed condensate storage device 3 when the temperature is higher than the condensation temperature. The condensate solution covers the surface of the electronic material, and the temperature adjustment device 2 is activated. , so that the fixed condensate is cooled below the condensation temperature (14-19°C), the solution is solidified, and the electronic material is cut after the cutter head is aligned accurately; while processing, cooling water is used to cool the cutter at 1-8°C The circulating cooling water of the cutter head can effectively avoid the problem th...

Embodiment 2

[0035] In the present embodiment, the fixed condensate adopts glacial acetic acid and dimethyl sulfoxide and 10 -6 mol / L 2-mercapto-5-methyl-1,3,4-thiadiazole, wherein the mixing ratio of dimethyl sulfoxide and glacial acetic acid is 90:1, and its machining process is as in Example 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com